Automotive methanol gasoline M40-M85 and preparation method thereof

A M40-M85, methanol technology for vehicles, applied in the petroleum industry, liquid carbon-containing fuels, fuel additives, etc., to achieve the effects of overcoming blockage of oil pipelines and fuel injection pipes, reducing pollution, and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

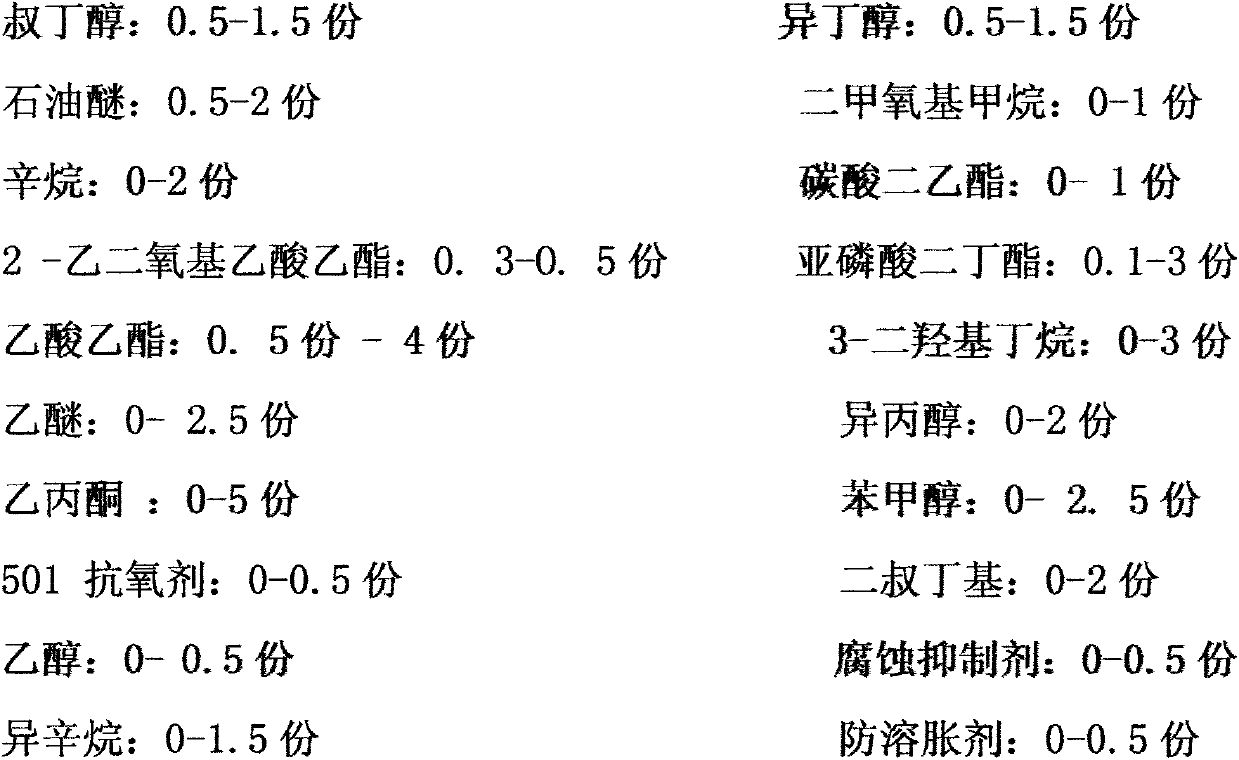

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of M40 methanol gasoline for vehicles is as follows. First, 6 kg of tert-butanol, 1 kg of isobutanol, 5 kg of petroleum ether, 0.2 kg of dimethoxymethane, 0.15 kg of octane, 1 kg of diethyl carbonate, 1 kg of isooctyl 1 kg of alkane, 3 kg of ethyl 2-ethylenedioxyacetate, 1 kg of dibutyl phosphite, 5 kg of ethyl acetate, 0.1 kg of 3-dihydroxybutane, 0.15 kg of ether, 2 kg of isopropanol, 1 kg of acetone, 1 kg of benzyl alcohol, 0.2 kg of 501 antioxidant, 0.2 kg of di-tert-butyl, 1 kg of ethanol, 0.5 kg of corrosion inhibitor, and 0.5 kg of anti-swelling agent are mixed in the container and stirred to obtain 30 kg of M40 additive , then this 30 kilograms of M40 additives and 370 kilograms of methyl alcohol, 600 kilograms of common national standard gasolines are put into the synthetic tank, inject finished product tank after mixing successfully, obtain 1000 kilograms of product M40 methanol gasoline for vehicles.

Embodiment 2

[0037] The preparation method of M60 methanol gasoline for vehicles is as follows. First, 2 kg of tert-butanol, 4 kg of isobutanol, 2 kg of petroleum ether, 0.15 kg of dimethoxymethane, 0.15 kg of octane, 0.5 kg of diethyl carbonate, isooctyl 0.5 kg of alkane, 2 kg of ethyl 2-ethylenedioxyacetate, 1 kg of dibutyl phosphite, 3 kg of ethyl acetate, 0.15 kg of 3-dihydroxybutane, 0.15 kg of ether, 1 kg of isopropanol, Mix 0.5 kg of acetone, 0.5 kg of benzyl alcohol, 0.2 kg of 501 antioxidant, 0.2 kg of di-tert-butyl, 1 kg of ethanol, 0.5 kg of corrosion inhibitor, and 0.5 kg of anti-swelling agent into the container and stir to obtain 20 kg of M60 additive , then this 20 kilograms of M60 additives and 580 kilograms of methyl alcohol, 400 kilograms of ordinary national standard gasolines are put into the synthetic tank, inject finished product tank after mixing successfully, obtain 1000 kilograms of product M60 methanol gasoline for vehicles.

Embodiment 3

[0039] The preparation method of M75 methanol gasoline for vehicles is as follows. First, 3 kg of tert-butanol, 1 kg of isobutanol, 1 kg of petroleum ether, 0.15 kg of dimethoxymethane, 0.5 kg of diethyl carbonate, 2-ethylenedioxyacetic acid 1 kg of ethyl ester, 1 kg of dibutyl phosphite, 3 kg of ethyl acetate, 0.2 kg of 3-dihydroxybutane, 0.15 kg of ether, 1 kg of isopropanol, 0.5 kg of ethyl acetone, 0.5 kg of benzyl alcohol, 501 anti 0.35 kg of oxygen agent, 0.2 kg of di-tert-butyl, 1 kg of ethanol, 0.65 kg of corrosion inhibitor, and 0.7 kg of anti-swelling agent are mixed in the container and stirred to obtain 15 kg of M75 additive, and then the 15 kg of M75 additive is mixed with 735 kg of Methanol and 250 kilograms of ordinary national standard gasoline enter the synthesis tank, and after successful mixing, they are injected into the finished product tank to obtain 1000 kilograms of the product M75 methanol gasoline for vehicles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com