Dual modified, dual cure epoxy acrylate coating

An epoxy acrylate, dual curing technology, applied in the field of coatings, can solve the problems of poor impact resistance, high hardness of the paint film, poor flexibility, etc., and achieve the effect of good impact resistance, good flexibility, and fast curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

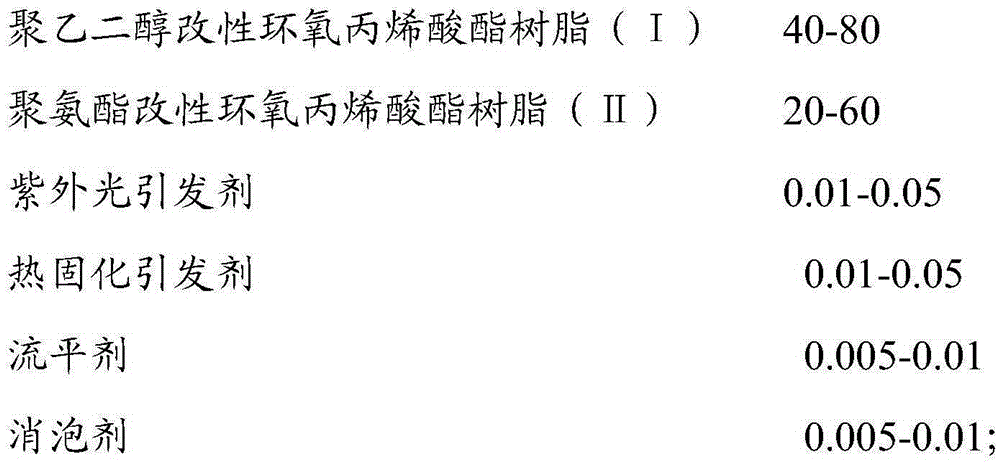

[0050] A kind of double modified, double cured epoxy acrylate coating of the present embodiment, comprises the raw material of following weight portion:

[0051]

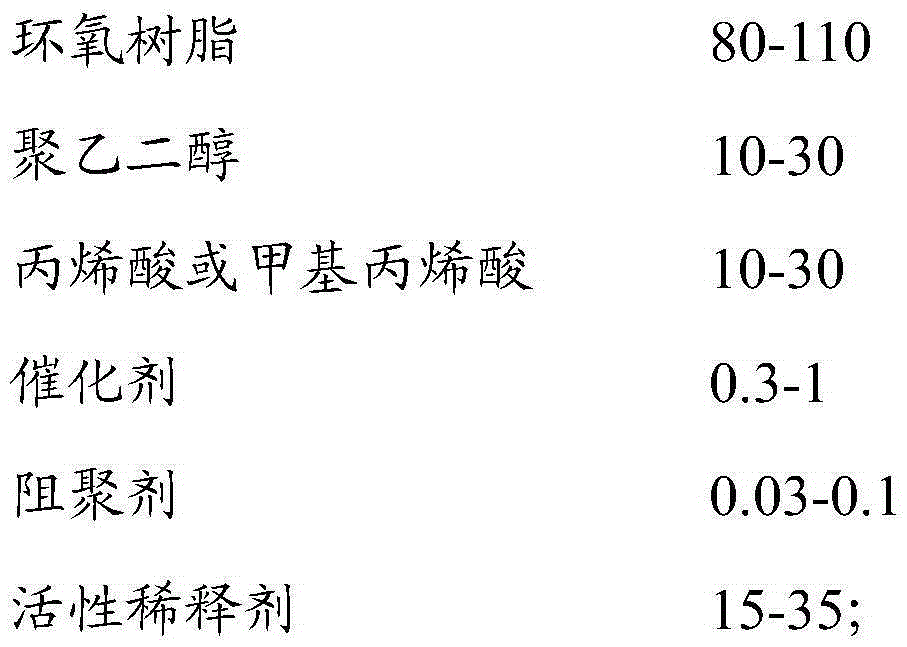

[0052] The polyethylene glycol modified epoxy acrylate resin (I) is prepared from the following raw materials in parts by weight:

[0053]

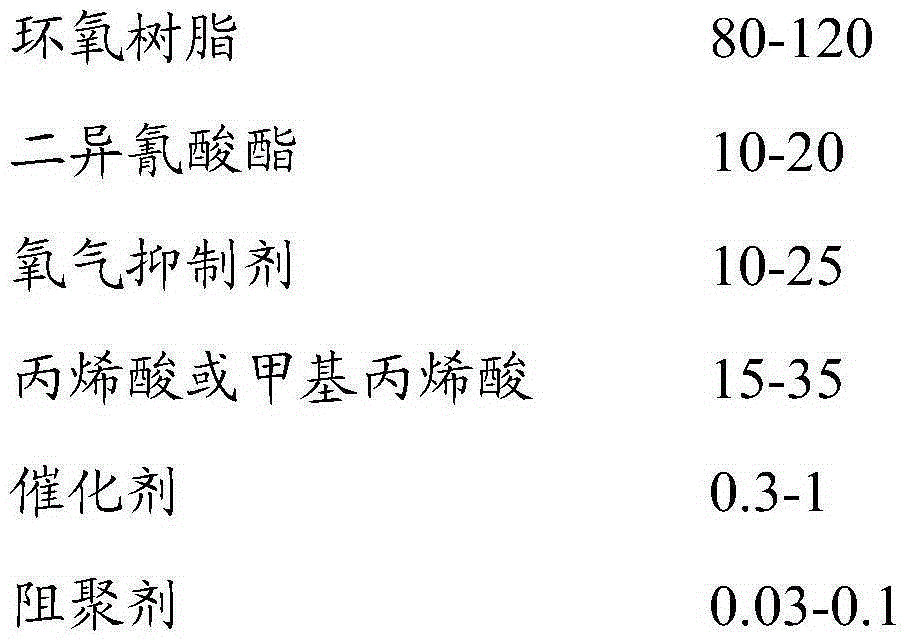

[0054] The polyurethane-modified epoxy acrylate resin (II) is prepared from the following raw materials in parts by weight:

[0055]

[0056] The preparation method of the epoxy acrylate paint of above-mentioned double modification, double curing, comprises the steps:

[0057] (1) Preparation of polyethylene glycol modified epoxy acrylate resin (I):

[0058] A, 80 parts by weight of epoxy resin E-42 and 10 parts by weight of polyethylene glycol with a molecular weight of 600 are added to reactor 1, while 0.3 parts by weight of triphenylphosphine (catalyst) and 0.03 parts by weight of Add hydroquinone (inhibitor) to Reactor 1 after mixing, and react at 95°C for 4 hours;...

Embodiment 2

[0070] A kind of double modified, double cured epoxy acrylate coating of the present embodiment, comprises the raw material of following weight portion:

[0071]

[0072] The polyethylene glycol modified epoxy acrylate resin (I) is prepared from the following raw materials in parts by weight:

[0073]

[0074] The polyurethane-modified epoxy acrylate resin (II) is prepared from the following raw materials in parts by weight:

[0075]

[0076] The preparation method of the epoxy acrylate paint of above-mentioned double modification, double curing, comprises the steps:

[0077] (1) Preparation of polyethylene glycol modified epoxy acrylate resin (I):

[0078] A. Add 90 parts by weight of epoxy resin E-44, E-51 (1:1 mass ratio) and 20 parts by weight of polyethylene glycol 600 into the reactor 1, while adding 0.5 parts by weight of triethylamine and 0.05 parts by weight of p-hydroxyanisole were mixed and added to Reactor 1, and reacted at 90°C for 3 hours;

[0079] B....

Embodiment 3

[0090] A kind of double modified, double cured epoxy acrylate coating of the present embodiment, comprises the raw material of following weight portion:

[0091]

[0092] The polyethylene glycol modified epoxy acrylate resin (I) is prepared from the following raw materials in parts by weight:

[0093]

[0094] The polyurethane-modified epoxy acrylate resin (II) is prepared from the following raw materials in parts by weight:

[0095]

[0096]

[0097] The preparation method of the epoxy acrylate paint of above-mentioned double modification, double curing, comprises the steps:

[0098] (1) Preparation of polyethylene glycol modified epoxy acrylate resin (I):

[0099] A. Add 100 parts by weight of epoxy resin E-42, E-51 (1:1 mass ratio) and 30 parts by weight of polyethylene glycol 400 into the reactor 1, and add 0.7 parts by weight of tetraethyl bromide Ammonium chloride and 0.07 parts by weight of p-hydroxyanisole were mixed and then added to the reaction kettle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com