150-DEG C irradiation cross-linking anti-blocking halogen-free flame-retardant insulating material and preparation method thereof

An insulating material and anti-adhesion technology, which is applied to insulators, insulated conductors, insulated cables, etc., can solve the problems of wire insulation layers sticking together, wires cannot be used normally, and cannot be separated normally, and achieves superior heat resistance and high resistance. Good flammability and resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

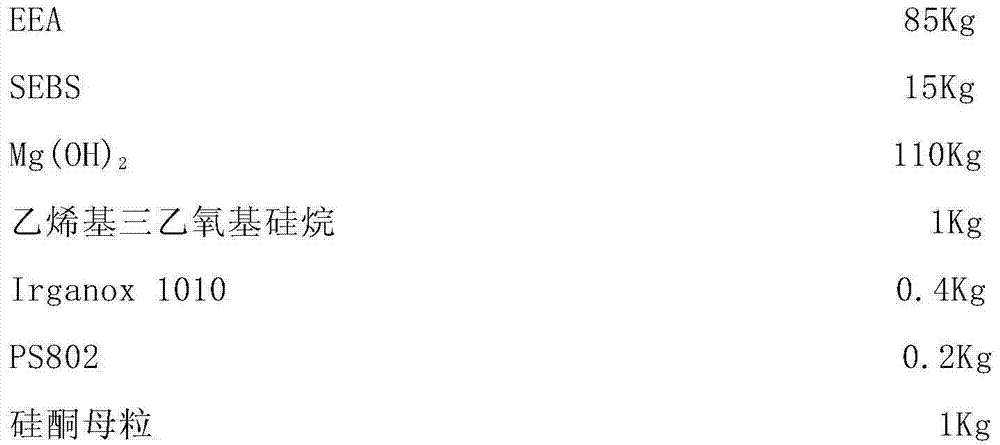

[0023] This example relates to a 150°C radiation cross-linking anti-blocking halogen-free flame-retardant insulating material. The names and parts by weight of the components contained in it are as follows:

[0024]

[0025] The preparation method of the above-mentioned invention comprises the following processing steps:

[0026] Mix magnesium hydroxide, vinyltriethoxysilane, Irganox 1010, and PS802 in proportion until the temperature reaches 70°C±5°C, leave the material out, and extrude and granulate with other components in proportion.

[0027] The product in Example 1 was tested for performance testing, and the performance values are shown in Table 1.

Embodiment 2

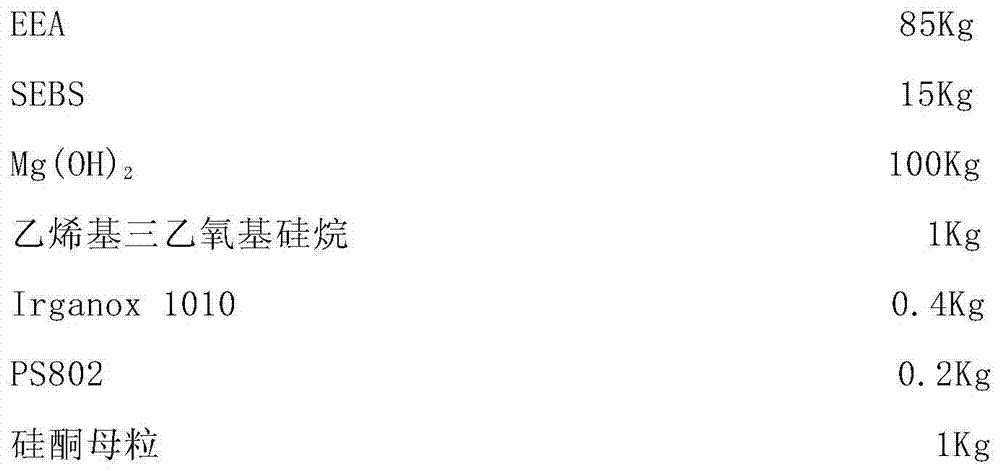

[0029] This example relates to a 150°C radiation cross-linking anti-blocking halogen-free flame-retardant insulating material. The names and parts by weight of the components contained in it are as follows:

[0030]

[0031] The preparation method of above-mentioned material is identical with embodiment 1

[0032] The product in Example 2 was tested for performance testing, and the performance values are shown in Table 1.

Embodiment 3

[0034] This example relates to a 150°C radiation cross-linking anti-blocking halogen-free flame-retardant insulating material. The names and parts by weight of the components contained in it are as follows:

[0035]

[0036] The preparation method of the above materials is the same as in Example 1.

[0037] The product in Example 3 was tested for performance testing, and the performance values are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com