Fire-retardant polyurethane foam and preparation method thereof

A technology of polyurethane foam and flame retardant, which is applied in the field of flame-retardant polyurethane foam and its preparation, can solve problems such as unsatisfactory effects, and achieve the effects of improving flame retardancy and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

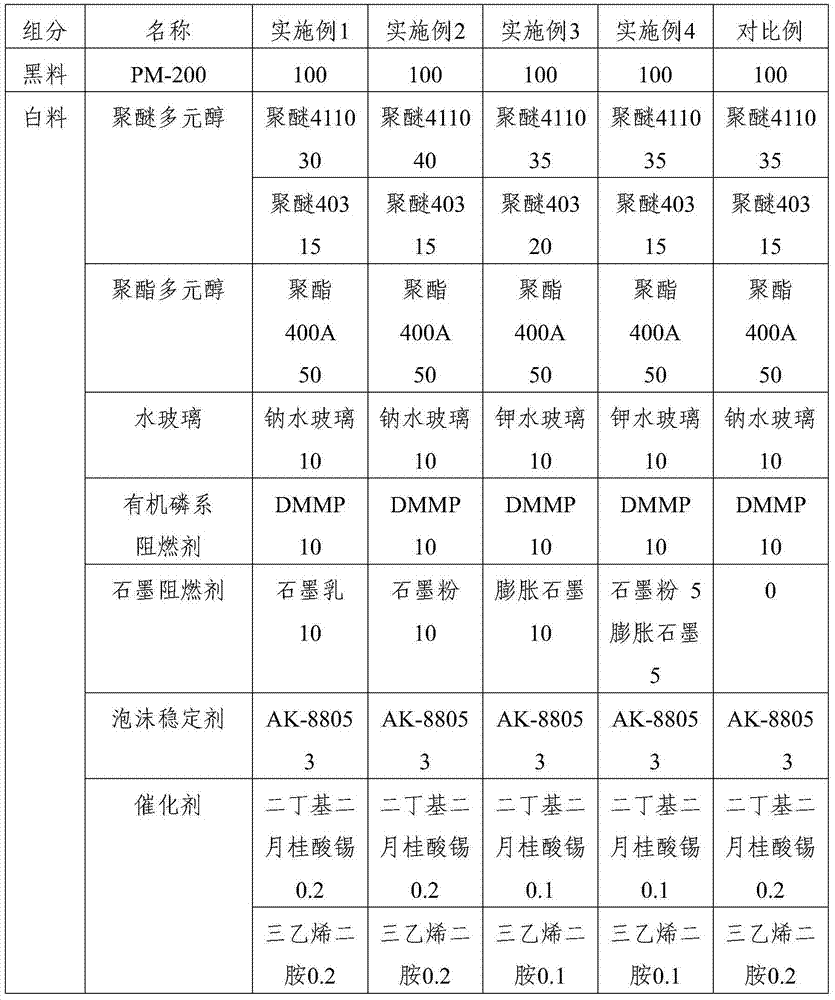

[0034] Polyurethane foam, the specific formula is shown in Table 1.

[0035] At room temperature, a certain amount of polyether polyol 4110, polyether polyol 403, polyester polyol 400A, sodium silicate, flame retardant DMMP, graphite milk, foam stabilizer AK-8805, dibutyl dilauric acid Put tin and triethylenediamine in a container and mechanically mix and stir for 20-30 minutes to form a uniform polyether system, which is white material.

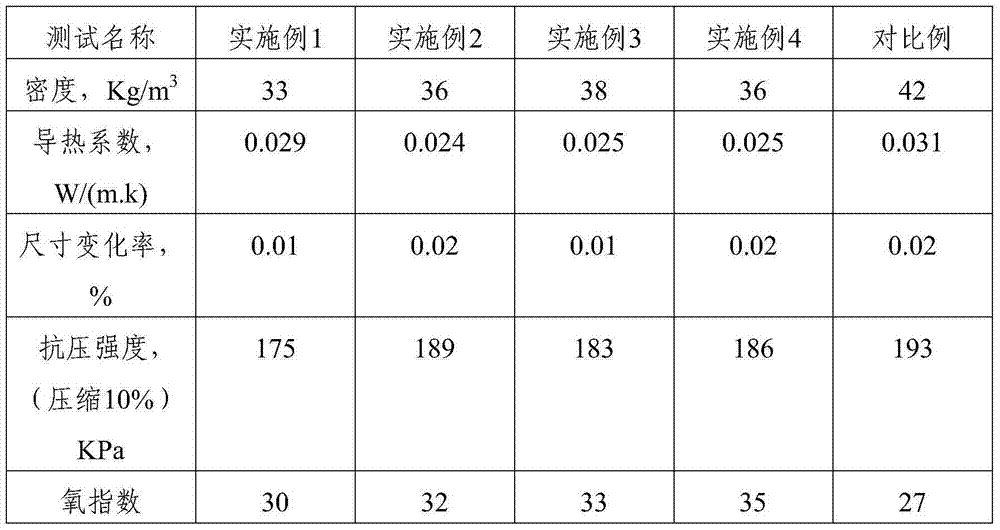

[0036] Then mix and react the white material with polymethylene polyphenyl polyisocyanate (PAPI) PM-200 at room temperature, stir at 1500r / min for 10s, then pour it into a constant temperature vertical climbing mold for foaming and solidification. After the foam is matured, This was removed from the mold to obtain a polyurethane foam. Carry out pattern cutting in accordance with the requirements of the national standard, and measure various properties of the foam body, see Table 2.

Embodiment 2

[0038] Polyurethane foam was prepared according to the method of Example 1. The specific formula is shown in Table 1.

[0039] Wherein, the stirring time is 5s; the stirring speed is 1800r / min.

Embodiment 3

[0041] Polyurethane foam was prepared according to the method of Example 1. The specific formula is shown in Table 1.

[0042] Wherein, the stirring time is 20s; the stirring speed is 1200r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com