Soft magnetic NiCuZn ferrite material with characteristics of wide temperature range, low temperature coefficient, high frequency and low loss, and preparation method thereof

A low temperature coefficient, ferrite material technology, applied in the direction of inorganic material magnetism, can solve the problems of small magnetic permeability and difficult linear change of positive value, and achieve the effect of small temperature change, low loss and low temperature coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

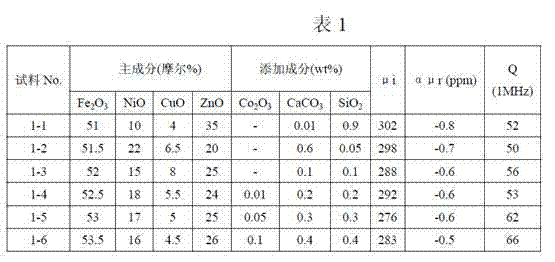

[0027] The main components and subcomponents were mixed in predetermined amounts as shown in Table 1.

[0028] The preparation method is:

[0029] a. Primary ball milling: Mix the components of the main component according to the ratio, and pass the obtained mixture through wet primary ball milling. The average particle size of the granular material after the primary ball milling is 0.8-1.5 μm.

[0030] b. Pre-burning: Pre-burn the pellets after the primary ball milling in the air. The pre-burning temperature is controlled at 750°C and kept for 4 hours.

[0031] c. Secondary ball milling: perform wet secondary ball milling on the calcined granules together with the auxiliary components. The average particle size of the granules after the secondary ball milling is 0.8-1.2 μm.

[0032] d. Forming and sintering: dry the granules after secondary ball milling, add a polyvinyl alcohol solution with a concentration of 15wt% of 11wt% of the pre-fired material, mix evenly, spray granu...

Embodiment 2

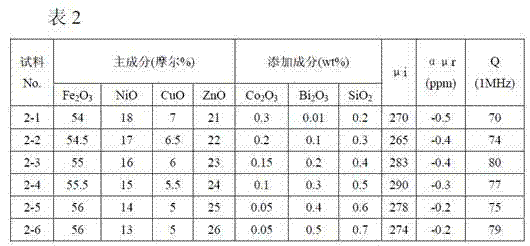

[0044] The main components and subcomponents were mixed in predetermined amounts as shown in Table 2.

[0045] The preparation method is:

[0046]a. Primary ball milling: Mix the components of the main component according to the ratio, and pass the obtained mixture through wet primary ball milling. The average particle size of the granular material after the primary ball milling is 0.8-1.5 μm.

[0047] b. Pre-burning: Pre-burn the pellets after primary ball milling in the air, the pre-burning temperature is controlled at 1050°C, and the temperature is kept for 0.5 hours.

[0048] c. Secondary ball milling: perform wet secondary ball milling on the calcined granules together with the auxiliary components. The average particle size of the granules after the secondary ball milling is 0.8-1.2 μm.

[0049] d. Molding and sintering: dry the granules after secondary ball milling, add a polyvinyl alcohol solution with a concentration of 10wt% of 13wt% of the weight of pre-fired mater...

Embodiment 3

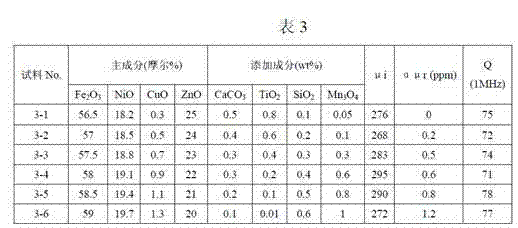

[0063] The main components and subcomponents were mixed in predetermined amounts as shown in Table 3.

[0064] The preparation method is:

[0065] a. Primary ball milling: Mix the components of the main component according to the ratio, and pass the obtained mixture through wet primary ball milling. The average particle size of the granular material after the primary ball milling is 0.8-1.5 μm.

[0066] b. Pre-burning: Pre-burn the pellets after primary ball milling in the air. The pre-burning temperature is controlled at 910°C and kept for 2.5 hours.

[0067] c. Secondary ball milling: perform wet secondary ball milling on the calcined granules together with the auxiliary components. The average particle size of the granules after the secondary ball milling is 0.8-1.2 μm.

[0068] d. Molding and sintering: dry the granules after secondary ball milling, add a polyvinyl alcohol solution with a concentration of 12wt% of the pre-fired material weight 12wt%, mix evenly, spray gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com