Wastewater zero discharge method in manufacturing process of island superfine fiber synthetic leather

A technology of ultra-fine fiber and manufacturing process, applied in chemical instruments and methods, neutralized water/sewage treatment, animal processing wastewater treatment, etc., to achieve zero discharge of wastewater, reduce water resource consumption, and improve technical level and status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

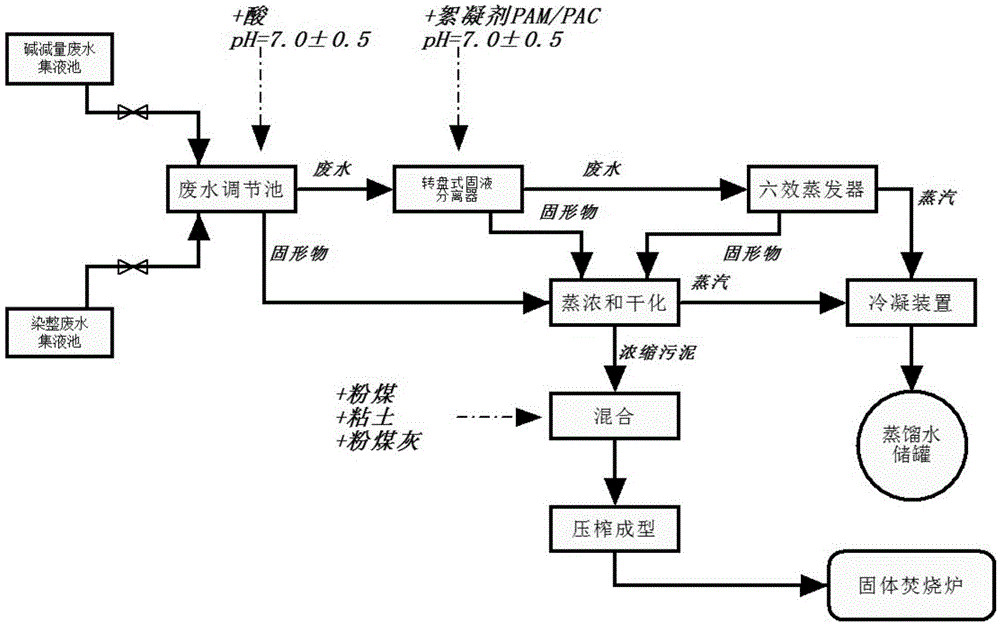

Image

Examples

Embodiment 1

[0054] For a Dingdao-type microfiber synthetic leather factory with an output of 75,000 m / day, the production of alkali-reduced sewage is about 1,500 tons / day, and 360,000 tons of distilled water can be recycled every year. The cost of distilled water manufacturing is calculated at 5 yuan / ton, only For distilled water, the annual cost savings is 1.8 million yuan. The waste water treatment cost of the present invention is about 0.56 yuan per meter of product, and the sewage treatment cost of the traditional technology is about 0.8 yuan per meter of product, and the invention reduces the cost of pollution. This embodiment takes the treatment of alkali weight reduction wastewater as an example to introduce a specific production method.

[0055] (1) Wastewater collection:

[0056] Build an alkali reduction wastewater collection pool and a wastewater adjustment pool; collect 1,500 tons of alkali reduction wastewater generated every day in the alkali reduction wastewater collection...

Embodiment 2

[0067] For a Dingdao type microfiber synthetic leather factory with an output of 75,000 m / day, the production of alkali-reduced sewage is about 1,500 tons / day, dyeing and finishing wastewater is 2,000 tons / day, and 840,000 tons of distilled water can be recovered each year. The production cost of distilled water Calculated at 5 yuan / ton, only distilled water is used, and the annual cost savings is 4.2 million yuan. The waste water treatment cost of the present invention is about 1.3 yuan per meter of product, and the sewage treatment cost of the traditional technology is about 1.5 yuan per meter of product, and the invention reduces the pollution cost. This embodiment introduces specific production methods by taking the treatment of alkali reduction wastewater and dyeing and finishing wastewater as examples.

[0068] (1) Wastewater collection:

[0069] Construct the alkali reduction waste water collection pool and the dyeing and finishing waste water collection pool respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com