Method for preparing carbon nano tube through electron beam induced deposition

A technology of electron beam induction and carbon nanotubes, which is applied in the direction of carbon nanotubes, nanocarbons, nanotechnology, etc., can solve the problems of high impurity content, multiple structural defects, difficult control of arc discharge process, etc., and achieve the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

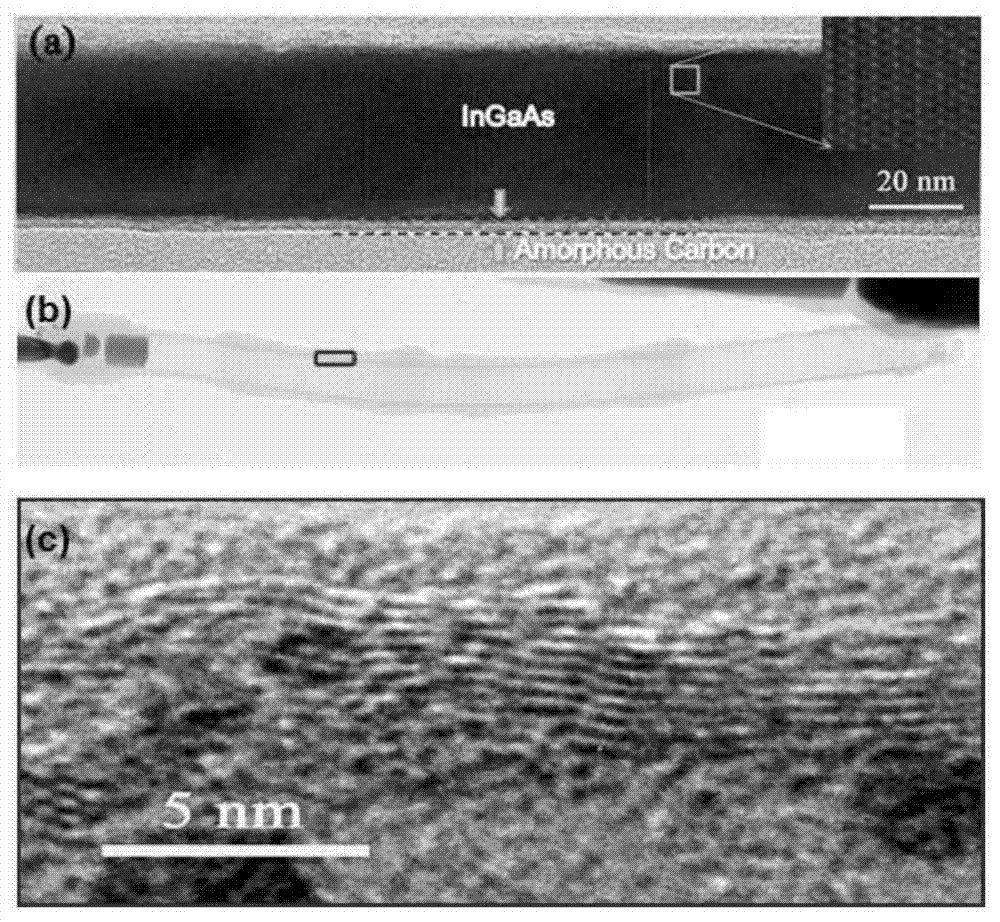

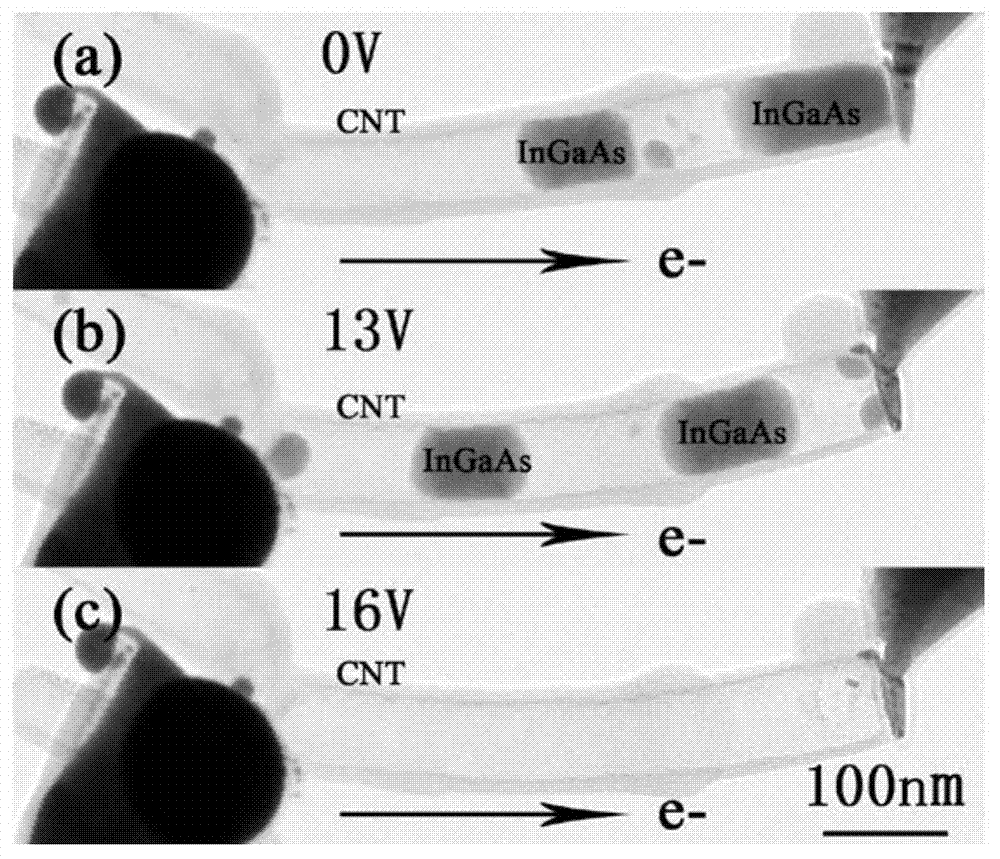

[0033] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and an example. InGaAs nanowires are used in the examples.

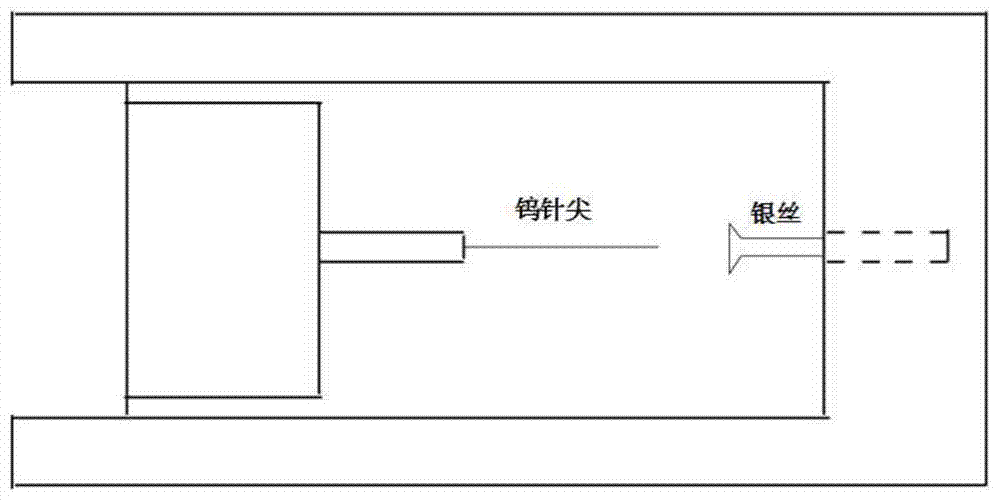

[0034] 1. Place the tungsten needle tip and the silver wire coated with InGaAs nanowires on the positive and negative electrodes of the electrical test platform, such as figure 1 As shown, put it into a high-resolution transmission electron microscope, and pump the vacuum; a piezoelectric ceramic sheet fixed at one end is connected to the electrical test platform, and the unfixed end of the piezoelectric ceramic sheet is used to place the tungsten needle tip, and the fixed end is externally connected with two The drive wire is externally connected to the drive power supply, and the piezoelectric ceramic sheet can be controlled by software to adjust the tungsten needle tip connected to it to move in three directions of x, y, and z. At the same time, the electrical test platform can be ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com