Eddy current retarder with torsional vibration reduction function

A technology of eddy current retarder and torsional vibration reduction, which is applied in springs/shock absorbers, motors, electric vehicles, etc., and can solve the problem of large fluctuations in rear axle gear load, large vibration and noise, and affecting the service life of rear axles, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

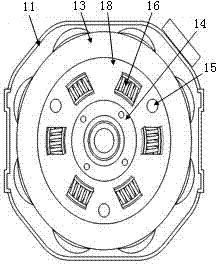

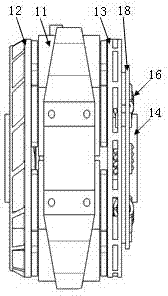

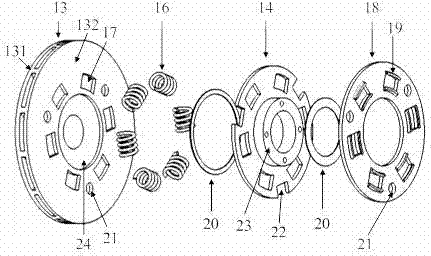

[0021] Examples of eddy current retarders with torsional vibration damping, such as Figure 1-3 As shown, the eddy current retarder with torsional vibration damping function includes a stator 11, an upstream rotor 12 and a downstream rotor 13, the upstream rotor 12 is used for connecting with the vehicle gearbox, and the downstream rotor 13 is used for connecting with the front end drive shaft of the rear axle of the vehicle connect. In addition, the downstream rotor 13 is provided with a vibration damping device for connecting with the drive shaft at the front end of the rear axle of the vehicle.

[0022] In this embodiment, the downstream rotor 13 is composed of an inner disk 131 and an outer disk 132 fixed together. There is a gap between the inner and outer disks, and the two are connected together by some connecting ribs at the edges. It is transmitted from the upstream rotor 12 to the outer disk 132 through the inner disk 131 . The shock absorbing and buffering device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com