Six-shaft stereo carving machine

A three-dimensional engraving machine, six-axis technology, applied in decorative arts, processing models, etc., can solve a large number of problems, damage the machine, and cannot be applied, and achieve the effects of high precision, flexible CNC electric spindle, and increased use range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

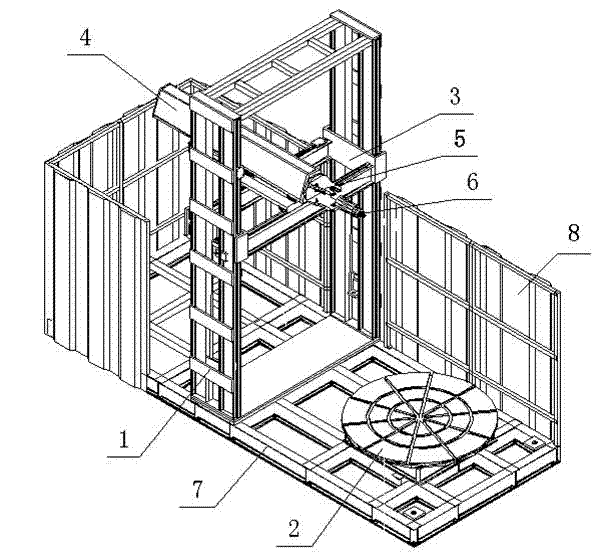

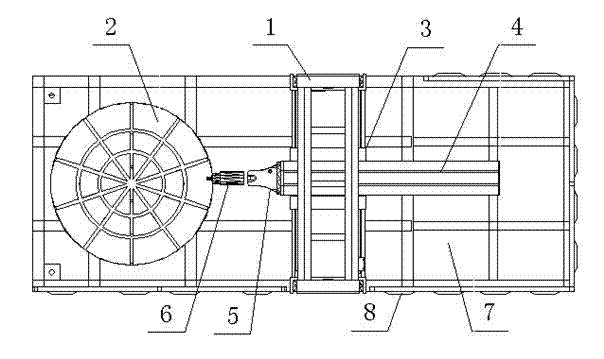

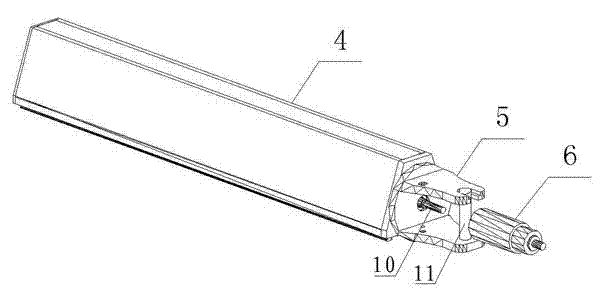

[0016] Such as figure 1 , figure 2 and image 3 As shown, a six-axis three-dimensional engraving machine includes a working machine table 2 for carrying and fixing objects to be carved, and two first shafts 1 arranged symmetrically on the left and right. A second shaft 3 is connected between the two first shafts 1. A first drive mechanism is provided between the first shaft 1 and the second shaft 3, so that the second shaft 3 can walk up and down in a straight line based on the first shaft 1, and a third shaft 4 is provided on the second shaft 3, so A second drive mechanism and a third drive mechanism are provided between the second axis 3 and the third axis 4, so that the third axis 4 can walk in a straight line from side to side and vertically from front to back based on the second axis 3. The third axis 4 The end corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com