Steel belt coiling machine

A steel coil and rack technology, applied in the field of equipment for processing steel strips into coils, can solve the problems of unguaranteed product quality, errors, time-consuming and labor-intensive efficiency, etc., so as to improve production efficiency, avoid errors, and ensure product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

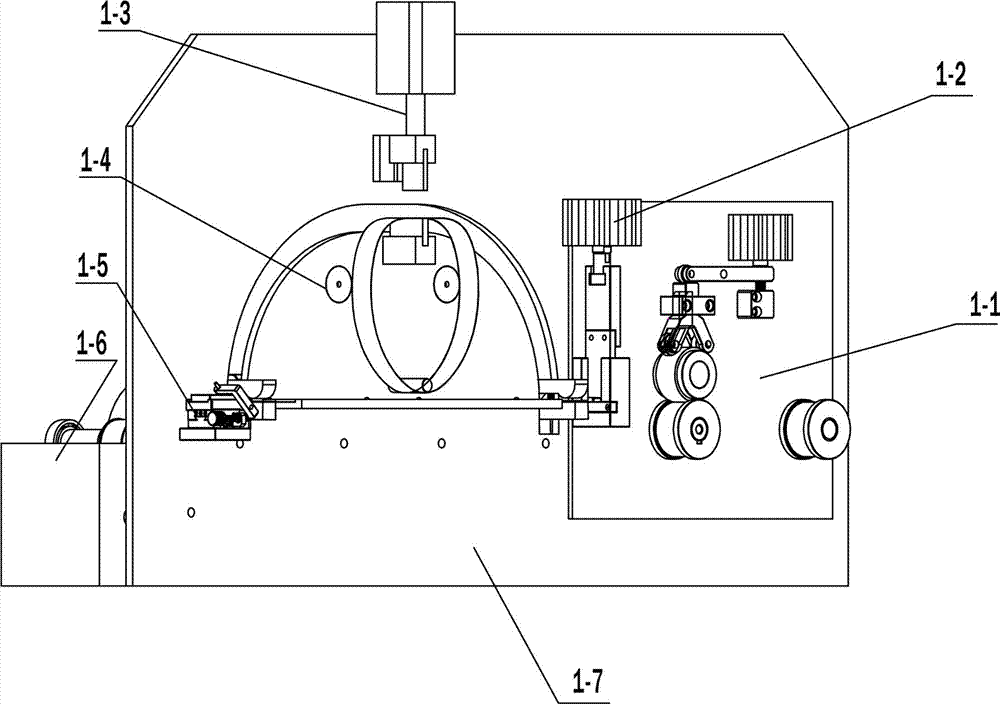

[0019] The structure of the present invention is as figure 1 As shown, a coiling steel strip machine includes a frame 1-7, and a feeding device 1-1, a clamping and shearing steel strip device 1-2, and a coiling device 1-4 are installed on the frame 1-7 , joint spot welding machine 1-3, unloading device 1-5 and transmission device 1-6.

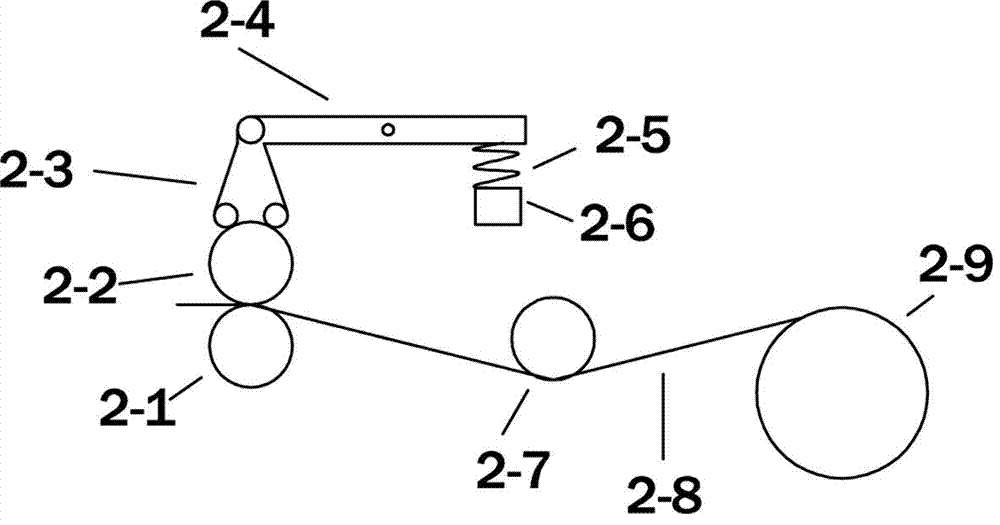

[0020] The feeding device 1-1 in the present invention is a double-roller feeding device, comprising an upper feeding roller 2-1 and a lower feeding roller 2-2 matched with the upper feeding roller 2-1, an upper feeding roller 2-1 and an upper feeding roller 2-1. The rollers 2-1 are all installed on the working plate, the upper feeding roller 2-1 is in contact with the pressing bracket 2-3, the pressing bracket 2-3 is connected with one end of the lever 2-4, and the other end of the lever 2-4 is connected with the fixed The spring 2-5 on the fixed support 2-6 is connected, and a straightening roller 2-7 is also provided in the feeding device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com