Auto-power-off explosion-proof conducting wire welding device and use method thereof

A technology of automatic power-off and welding equipment, applied in auxiliary equipment, welding equipment, metal processing, etc., can solve the problems of inability to meet the needs of mass production, inaccurate temperature control, low work efficiency, etc., and achieve simple structure and increased effective time , The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

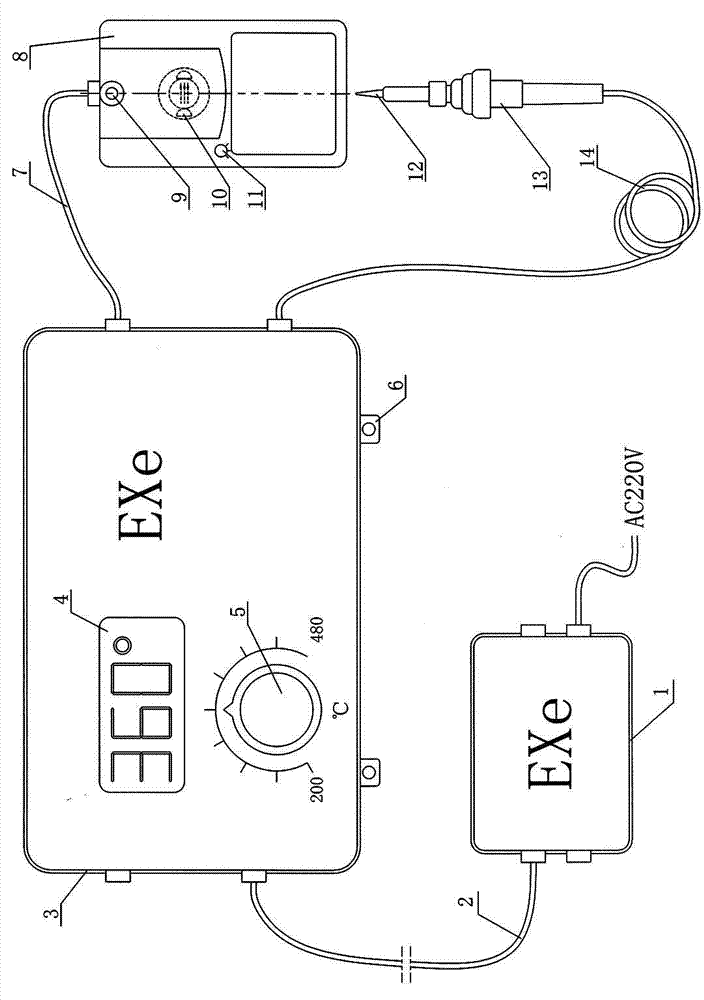

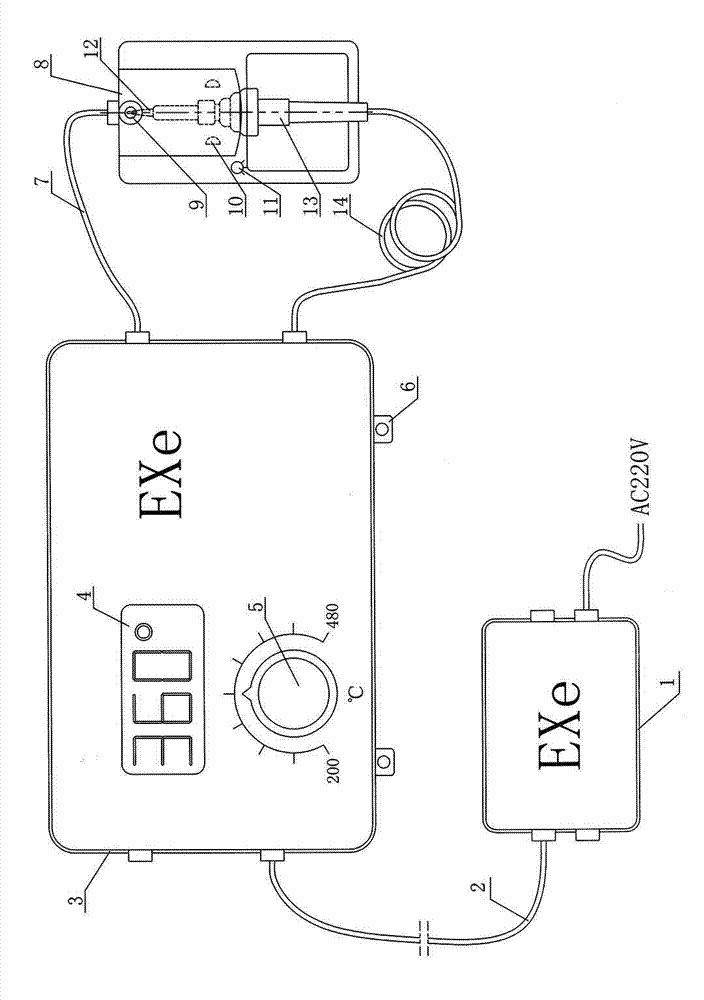

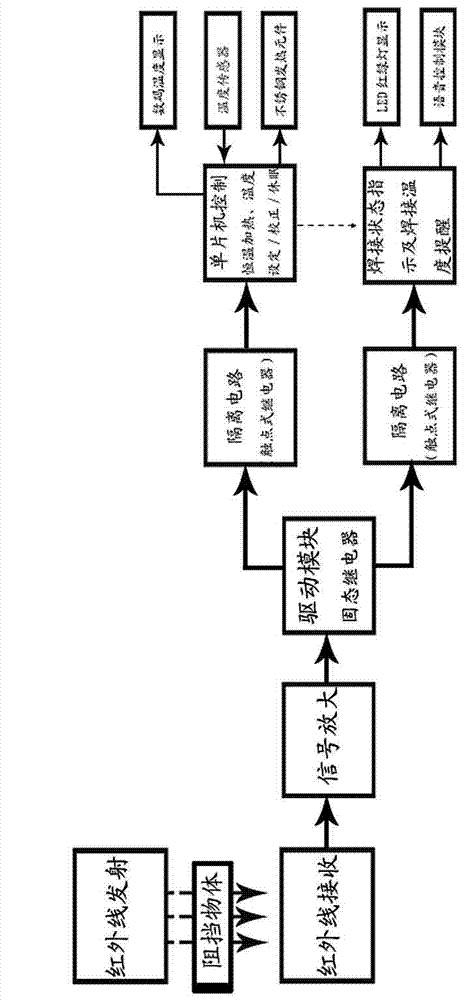

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the automatic power-off explosion-proof wire welding device of the present invention includes an explosion-proof isolated power supply 1, an explosion-proof control box 3, a soldering platform 8, an infrared emitting and receiving module 10, a soldering iron head 12, and a soldering iron handle 13; an explosion-proof isolated power supply 1 It is connected with the explosion-proof control box 3 through the armored cable 2; the explosion-proof isolated power supply 1 uses 220V input power, and is transformed by the built-in isolation transformer to output two safe voltages of 9V and 24V; these two safe voltages are respectively provided for the explosion-proof control box 3 Control power supply and heating power supply; the 9V control power supply is converted into a DC power supply by the rectifier module in the explosion-proof control box 3; the welding platform base 8 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com