Free forging oil press rack

A technology for hydraulic presses and racks, applied in forging/pressing/hammering machinery, forging/pressing/hammer devices, manufacturing tools, etc., can solve the problems of complex internal structure, easy generation of waste, long construction period, etc. The effect of short manufacturing cycle and shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

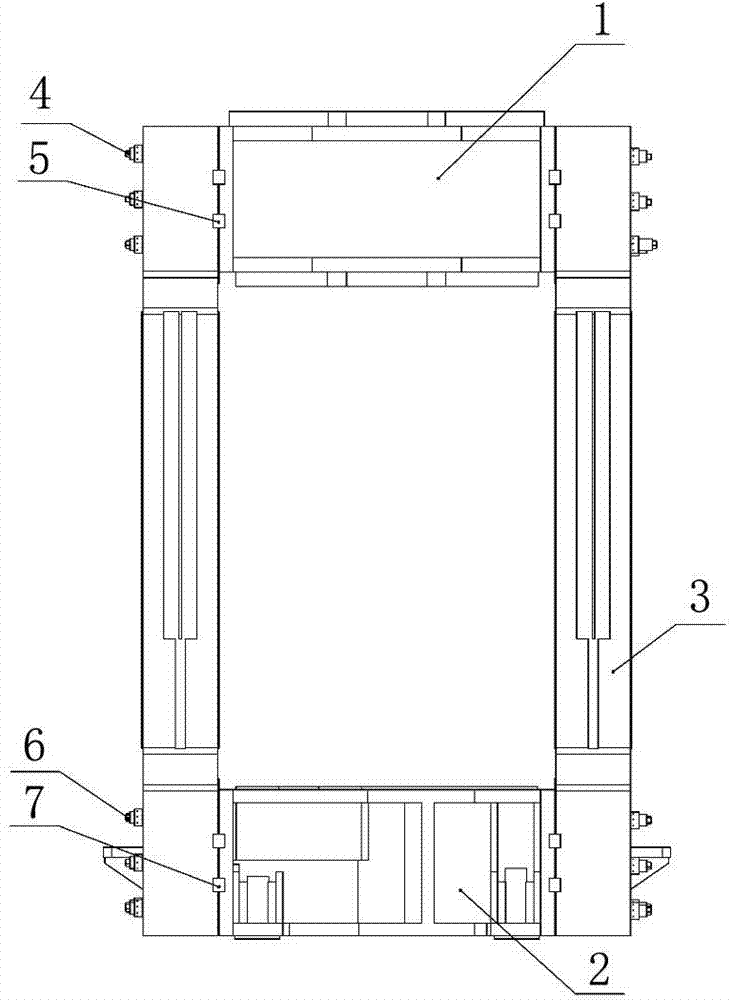

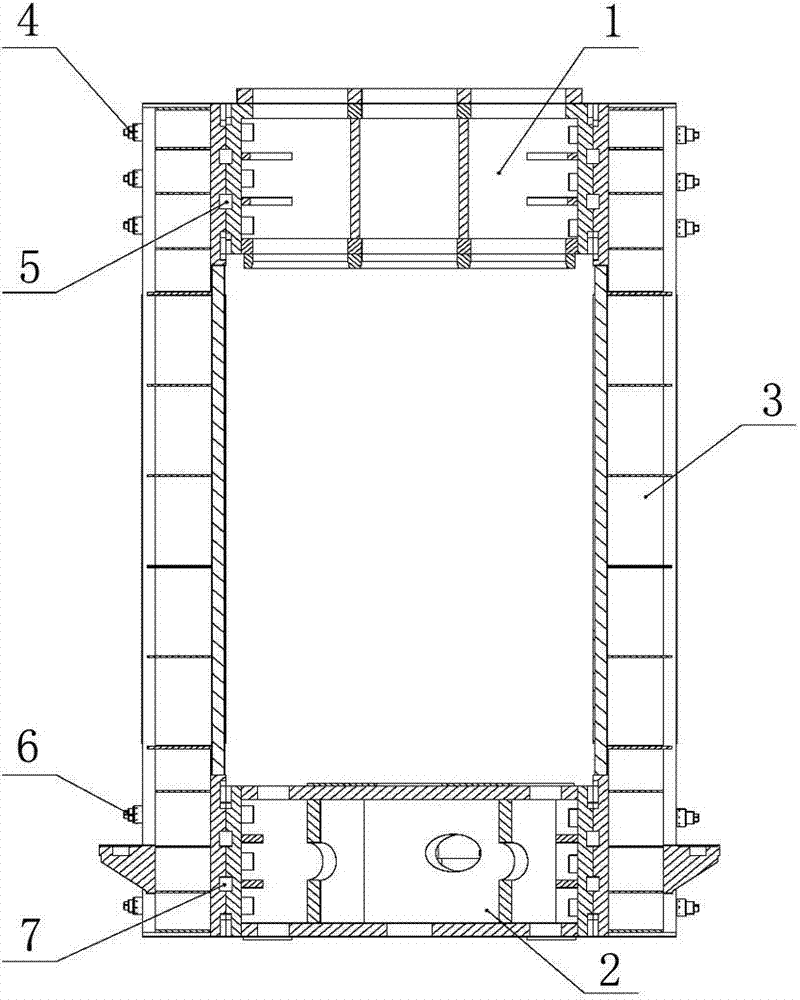

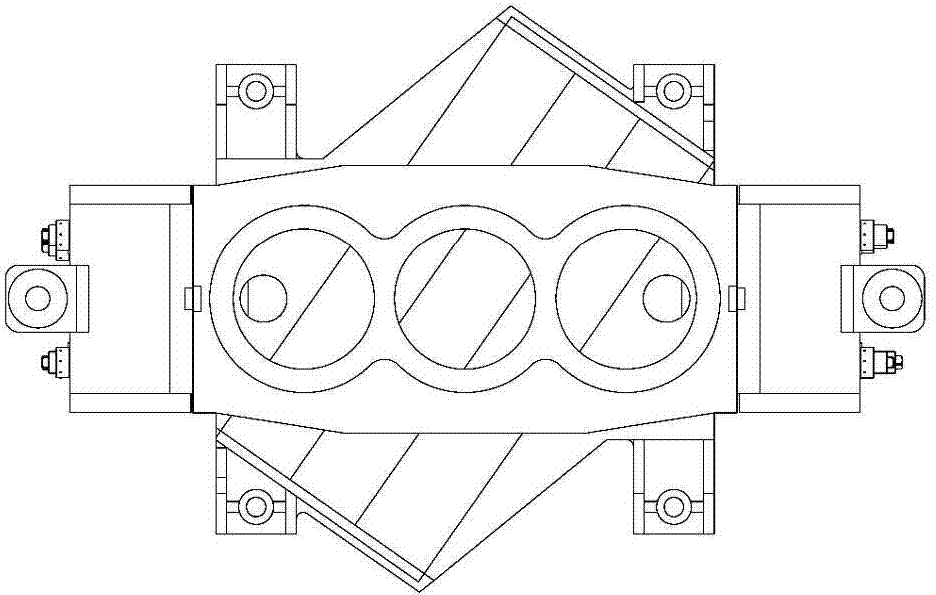

[0017] First, the technical solution provided by the present invention is applied to the frame of the 40MN free forging hydraulic press. As mentioned above, the frame includes an upper beam 1, a lower beam 2 and two columns 3 made by welding, and the upper beam 1. The shape and structure of the lower crossbeam 2 and the upright column 3 are basically similar to those of the parts of the frame obtained by casting. Wherein, the two columns 3 are vertically arranged symmetrically on both sides of the frame, the upper beam 1 is placed on the top of the frame and between the two columns 3, and the upper beam 1 is preloaded by the upper beam pull rod 4 Assembled together, a plurality of upper beam rectangular keys 5 are embedded in the rectangular key grooves reserved at the upper ends of the upper beam 1 and the two columns 3 . The lower crossbeam 2 is placed at the bottom of the frame and also between the two uprights 3, and is preloaded and assembled together by the lower beam ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com