Cold extrusion mold for blind hole inner spline

A technology of internal splines and cold extrusion, applied in the direction of metal extrusion dies, etc., can solve the problems of low production efficiency of slotting process, unsuitable for mass production, high production cost, etc., and achieve compact structure, high production efficiency, extrusion good pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

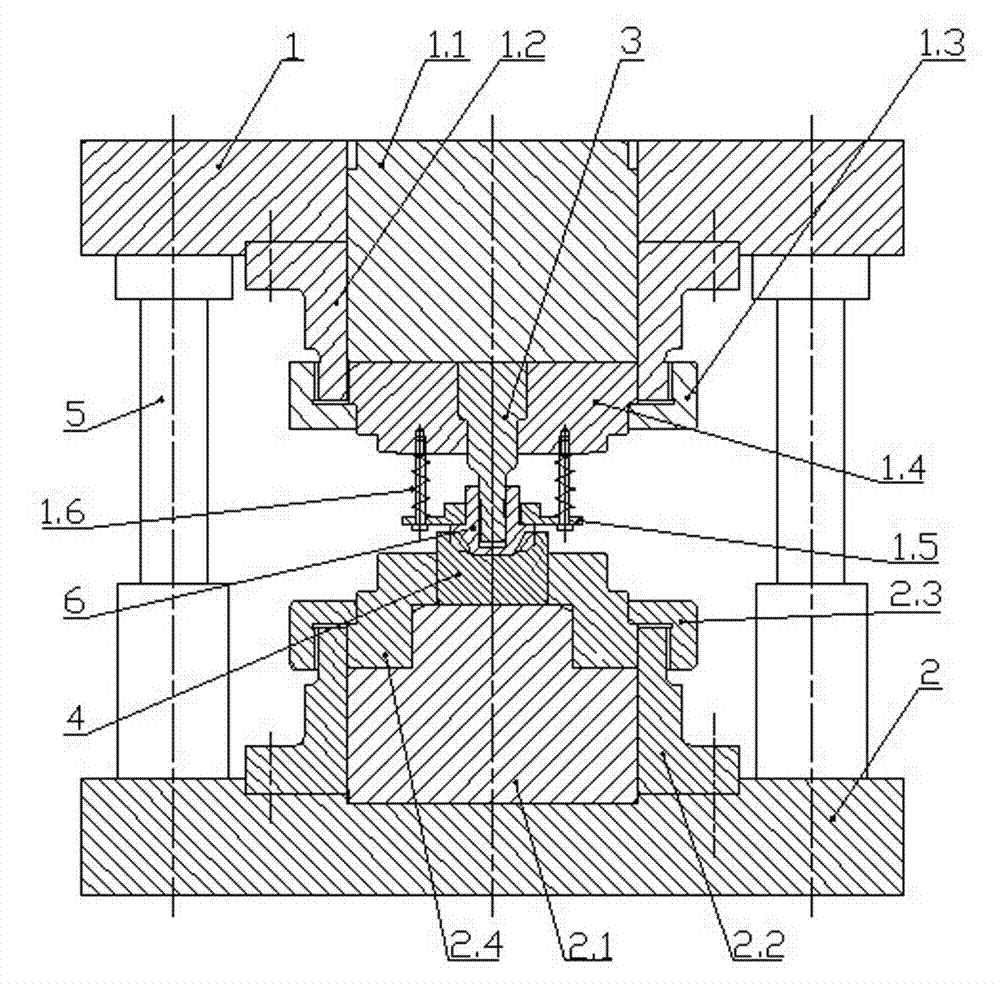

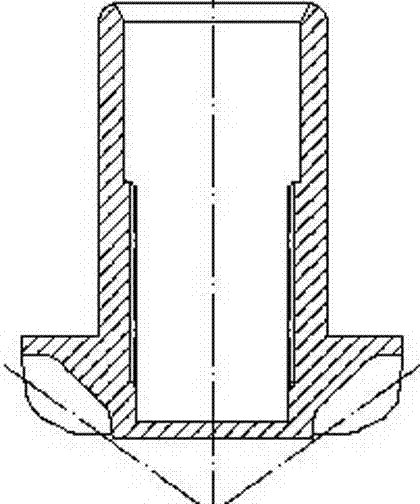

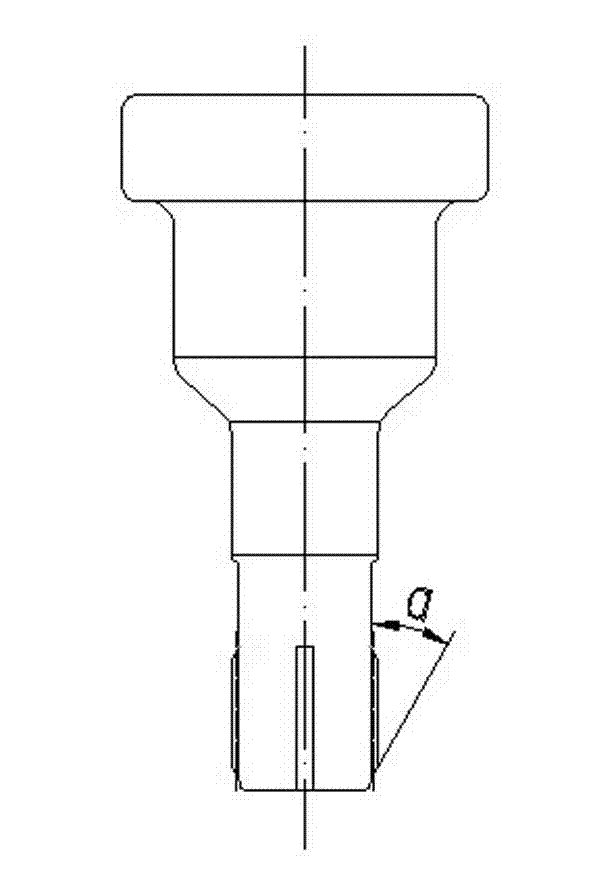

[0015] figure 1 The shown blind hole internal spline cold extrusion die includes a patrix and a bottom die, and the four corners between the patrix and the bottom die are connected by guide struts 5 to form a mold frame that can be relatively positioned and slid. The upper mold is located on the upper part of the mold base, and is directly controlled by the pressure head of the supporting press. The template 1 above the upper mold and the upper positioning sleeve 1.2 are used as the carrier for positioning and installing the upper spacer 1.1, the upper mold base 1.4 and the upper locking ring 1.3. The mouth of the upper locking ring 1.3 and the positioning sleeve 1.2 is a spiral connection structure, and the spiral structure is locked. Make the built-in upper cushion block 1.1 and the upper die base 1.4 into one. The lower mold uses t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com