Ultrasonic cleaning device for zippers

A cleaning device and ultrasonic technology, applied in cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problem that the zipper cloth is easy to be stained, affects the quality and appearance of the finished zipper, and is prone to oiling and other problems, to achieve the effect of guaranteeing service life, easy repair and sufficient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

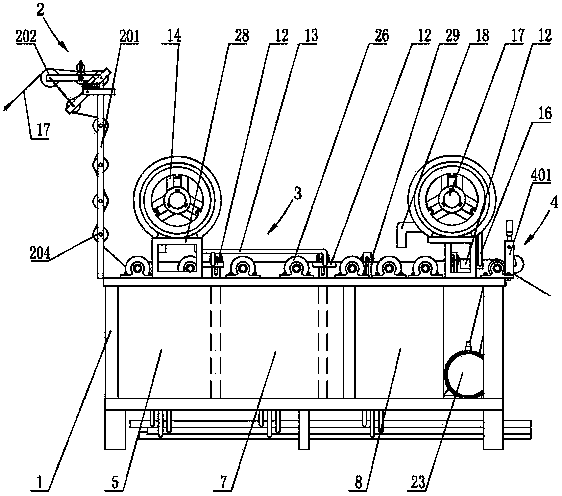

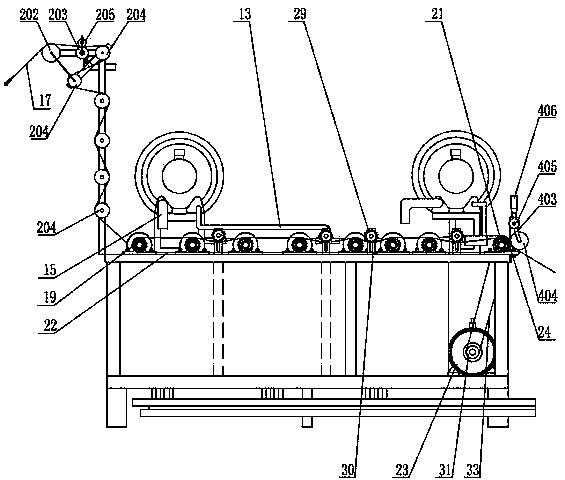

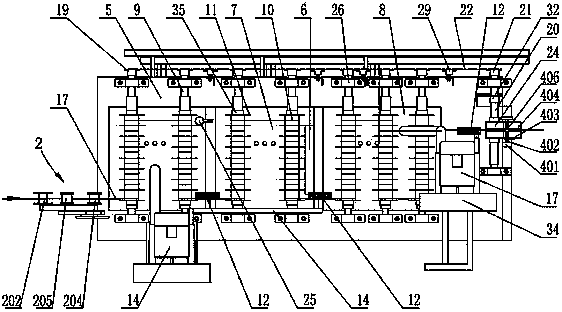

[0022] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0023] See figure 1 , figure 2 , image 3 , Figure 4 The zipper ultrasonic cleaning device disclosed in the preferred embodiment of the present invention comprises a frame 1, on which an inlet chain guide mechanism 2, a cleaning mechanism 3 and an outlet chain guide mechanism 4 are sequentially arranged on the frame 1, and the inside of the frame 1 is provided with a horizontal A plurality of water tanks arranged in sequence, the plurality of water tanks include a water tank one 5 with cleaning agent, a water tank two 7 equipped with an ultrasonic generating device 6 and a water tank three 8 equipped with clean water, and each of the water tanks is distributed through a pipeline. Equipped with water inlet pipe, water outlet pipe and overflow pipe; at least one transmission shaft 9 is arranged along the longitudinal direction of each w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com