System for controlling dioxin emission in flue gas in real time and working method thereof

A real-time control and flue gas technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve problems such as endangering the health of surrounding residents, dioxin super-standard emission, and the inability of online real-time monitoring of activated carbon adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

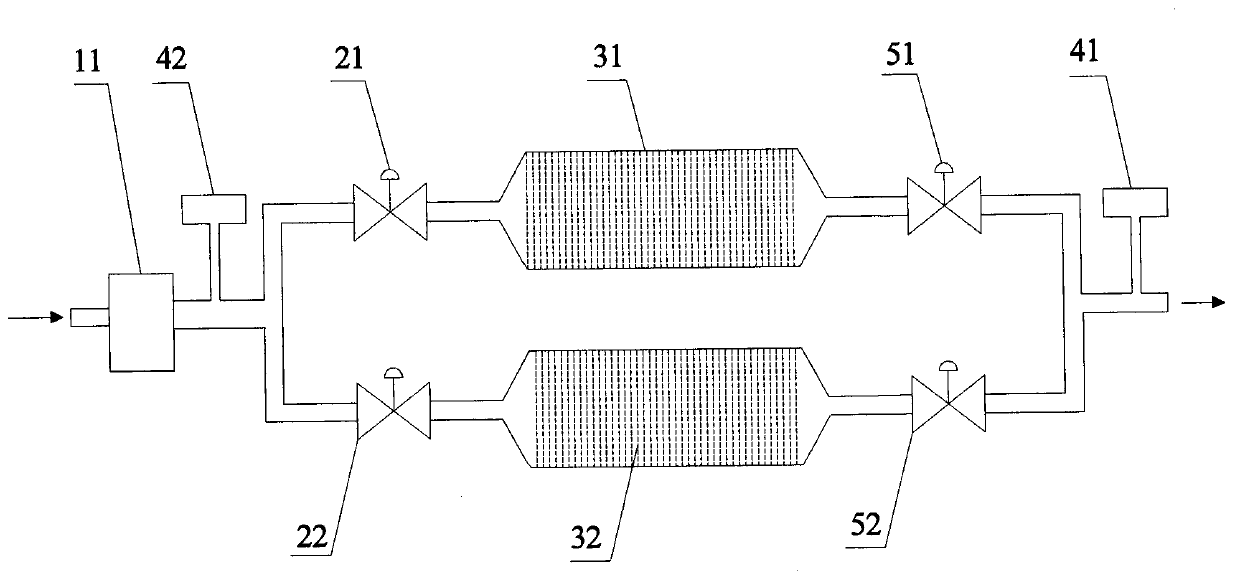

[0034] figure 1 Schematically provides a simplified structural diagram of a system for real-time control of dioxin emissions in flue gas according to an embodiment of the present invention, as figure 1 As shown, the system includes:

[0035] A pretreatment device 11, the pretreatment device 11 is used to remove dust, acidity, and odorous gases in the flue gas; the pretreatment device 11 is a prior art in the art, and will not be repeated here;

[0036] Switching components 21, 22, the switching components 21, 22 are used to selectively connect the outlet of the pretreatment device to any one of the two-way dioxin removal devices; the switching components are specifically: two valves are set, The flow path switching is realized by opening and closing the valve;

[0037] Two road dioxin removal devices, each road dioxin removal device includes: catalytic reactors 31, 32, the catalytic reactors are used to remove dioxins in flue gas, the structure and working principle of the r...

Embodiment 2

[0052] The system for removing dioxins in flue gas online in the embodiment of the present invention is different from Embodiment 2 in that: in each dioxin removal device, a first detector is arranged between the switching part and the reactor, and the reactor and the reactor Second detectors are arranged between the valves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com