Powder sticking machine

A technology of sticking and dipping powder, applied in food forming, food science, food coating and other directions, can solve the problems of excessive bacterial detection, unsuitable for mass production, unsanitary artificial powder sticking, etc., to ensure hygiene The effect of improving production efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

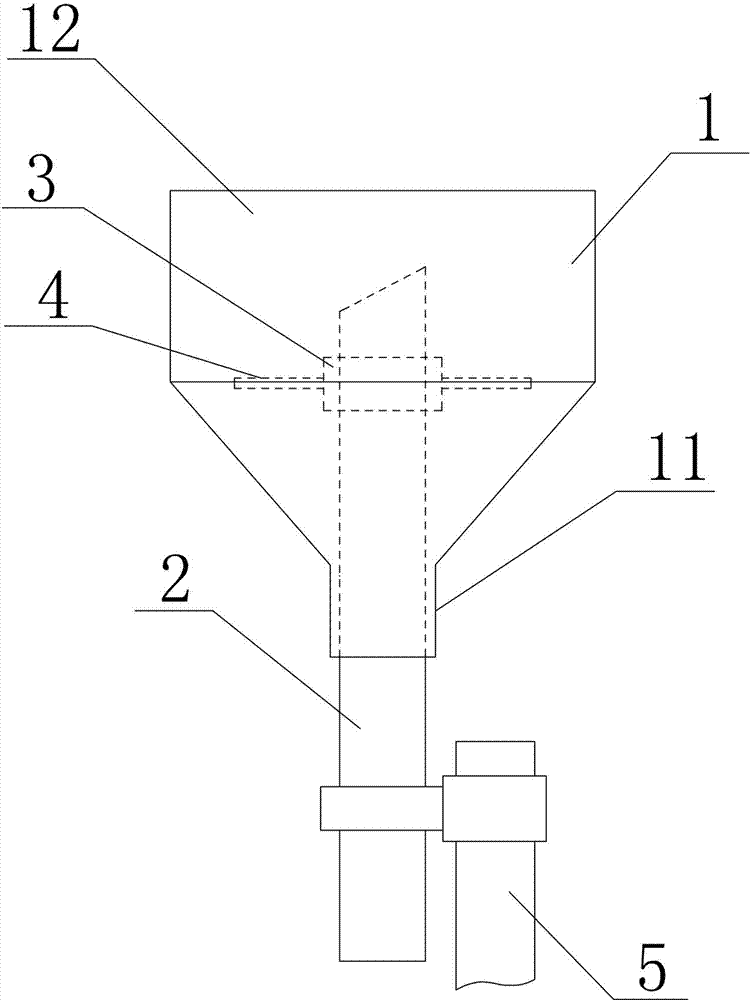

[0010] refer to figure 1 , a powder sticking machine, including a separation tube and a vertically suspended funnel 1, the funnel includes a funnel head 12 and a funnel neck 11, the funnel head 12 has a funnel mouth, the funnel mouth is the material and powder inlet, food materials and powder Enter the cavity of the funnel head 12 from the funnel mouth.

[0011] The separation pipe 2 is a stainless steel pipe, and the inner diameter of the separation pipe 2 is the same as that of the food material. The separation pipe 2 is inserted into the chamber of the funnel head 12 along the funnel neck 11 . The opening of the end of the separation tube 2 inserted into the funnel head 12 is an inclined plane, and a tube clip 3 is provided on the outer wall of the tube. A stirring blade 4 is fixed horizontally and annularly on the pipe clamp 3, and the stirring blade 4 is in the shape of a rectangular sheet.

[0012] The body of the separation pipe 2 located outside the funnel 1 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com