Non-overshoot LED linear constant current drive circuit

A linear constant current drive and constant current drive technology, which is applied in the layout of electric lamp circuits, electric light sources, lighting devices, etc., can solve the problems of reducing the working efficiency of the LED drive scheme, increasing the power consumption of the line circuit, and increasing the power consumption of the system. The effect of reducing design cost, improving efficiency and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail now in conjunction with accompanying drawing.

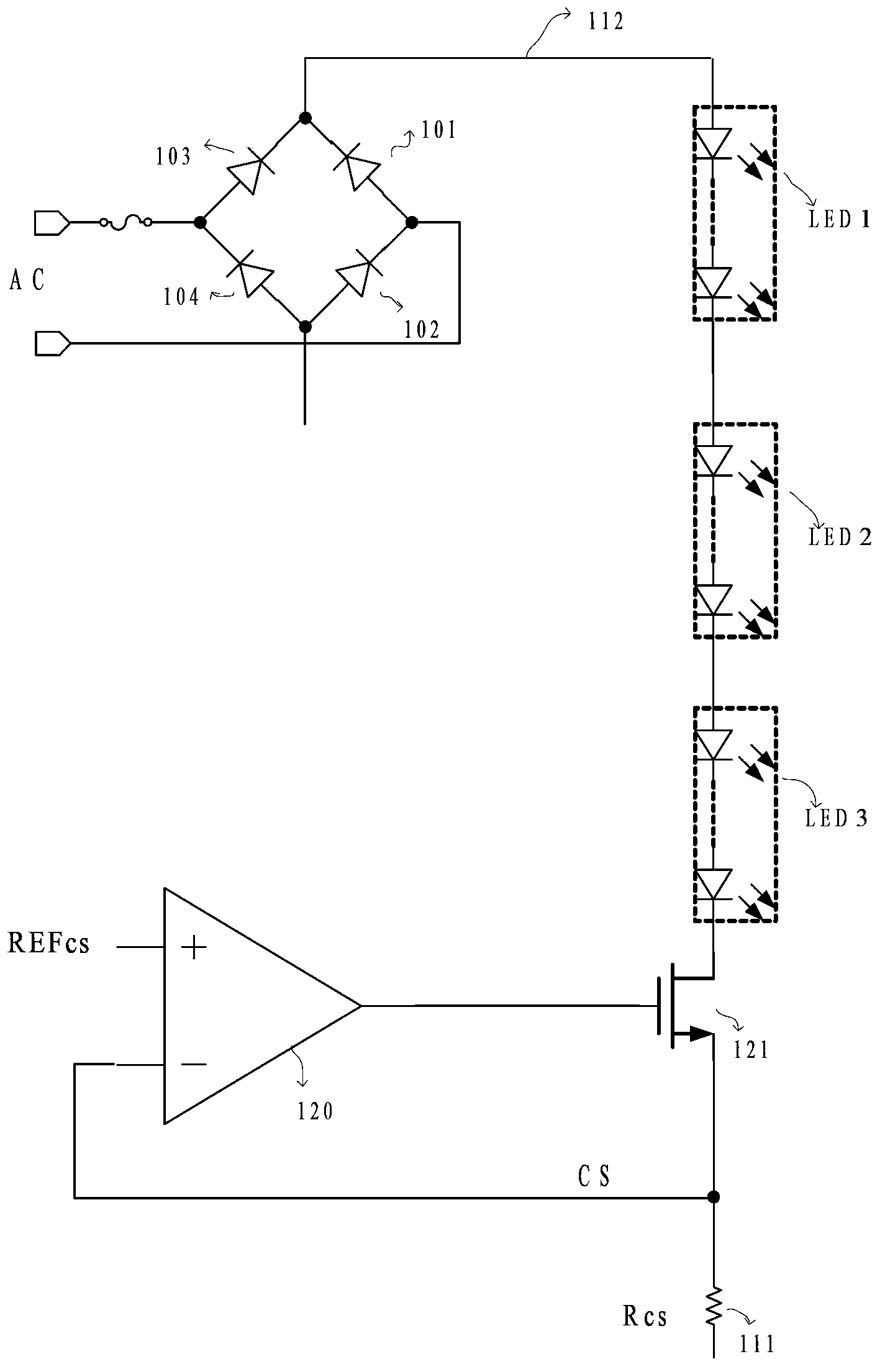

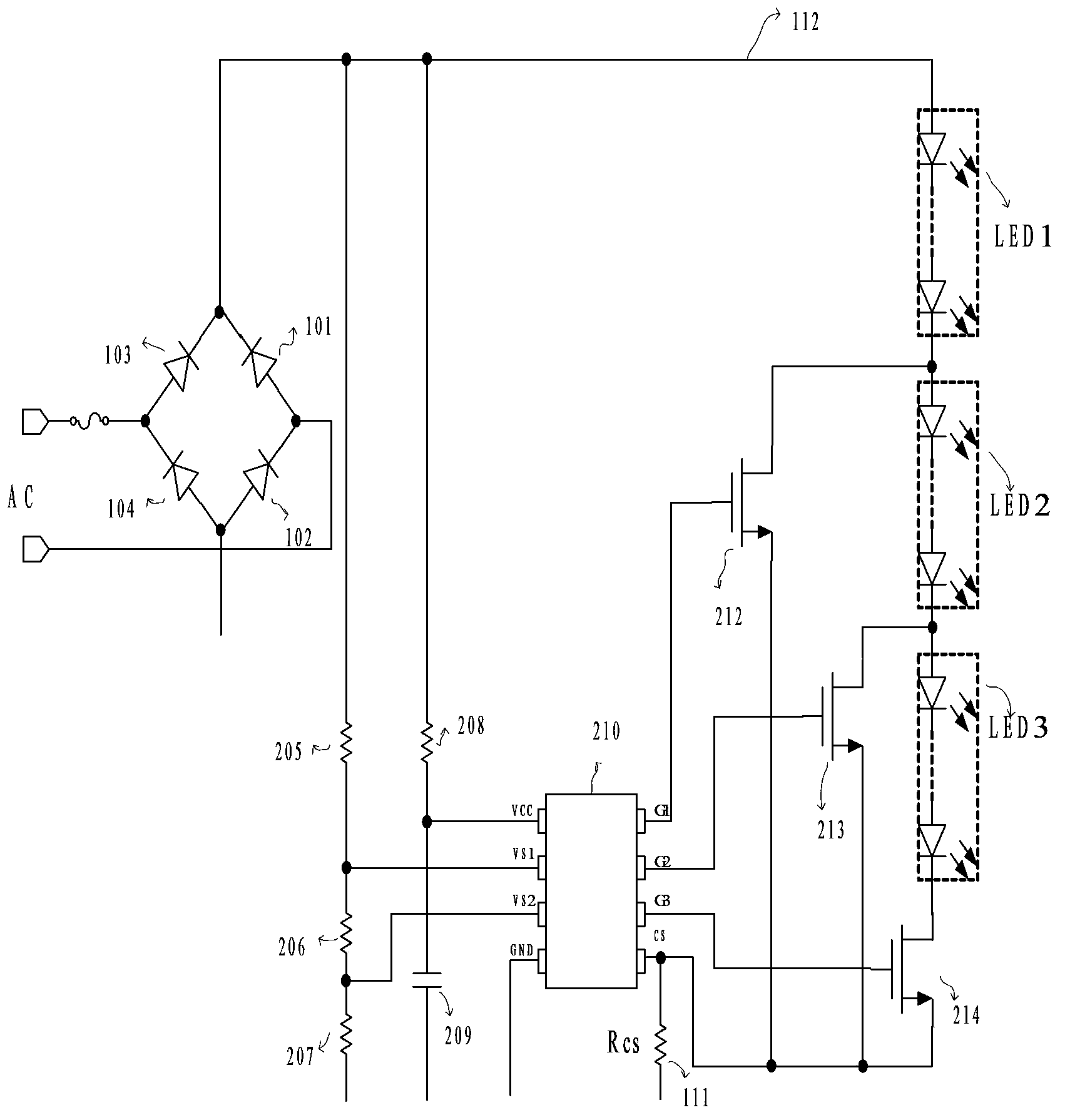

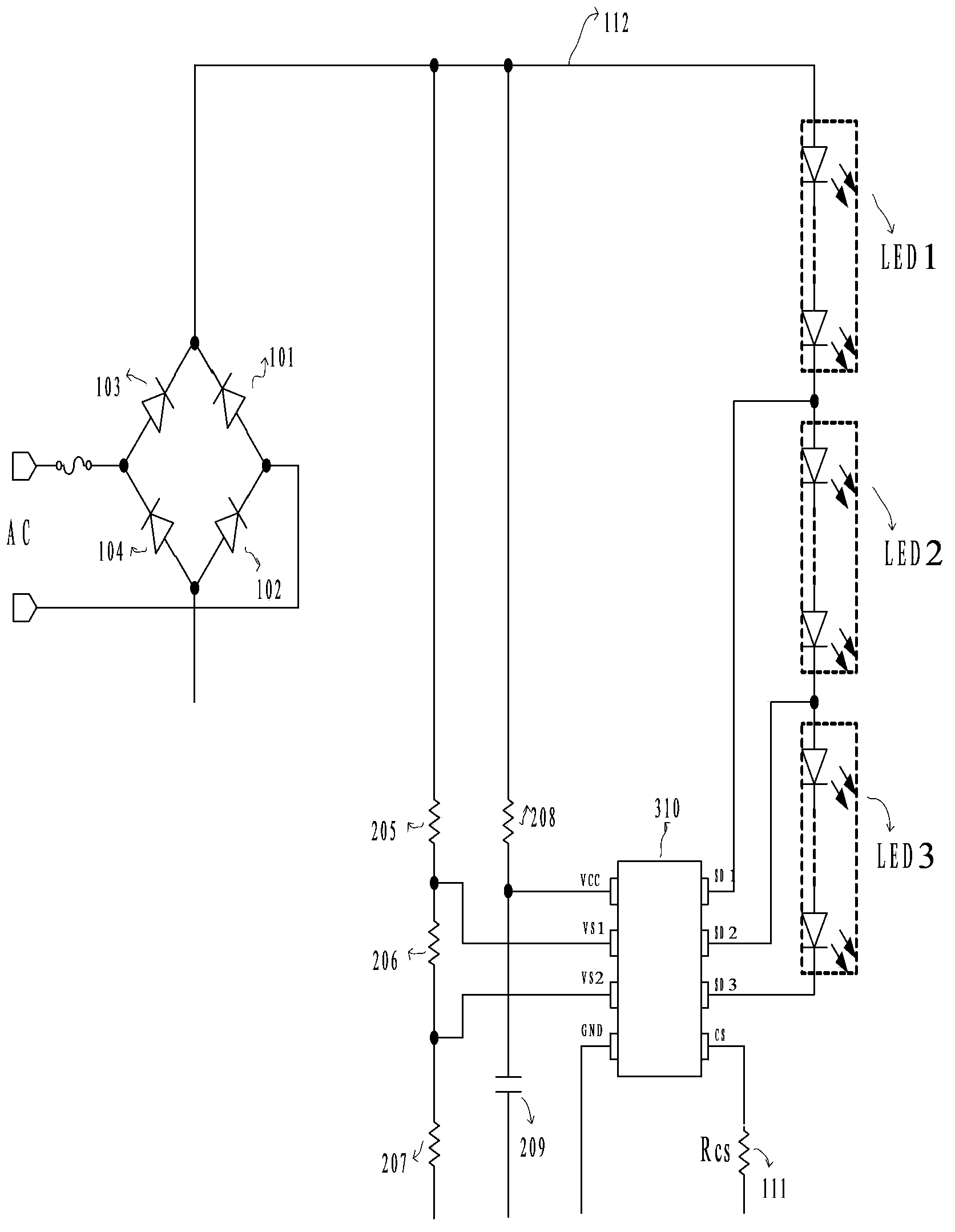

[0026] Such as figure 2 As shown, a non-overshoot LED linear constant current drive circuit. In the figure, rectifier diodes 101, 102, 103, 104 form an AC input rectifier bridge; LED light strings include three groups of LED1, LED2 and LED3, and each group of LEDs is composed of multiple LEDs, LED1, LED2 and LED3 are connected in series in sequence, and LED1’s The anode is connected to the output of the bridge rectifier. Resistors 205, 206 and 207 are connected in series to form an input voltage detection network. The core control unit of the LED constant current drive circuit uses the control IC 110, which is the core module of the high voltage LED linear constant current drive circuit, and is used to generate control signals for the LED control switches 212, 213, 214. The power supply network composed of the resistor 208 and the capacitor 209 provides power for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com