Shaping mechanism of wire harness crimping machine

A wire harness terminal, crimping machine technology, applied in the direction of connection, circuit/collector parts, electrical components, etc., can solve the frequent use of automatic crimping machine failure, thick copper wire is easy to deform, bend, and increase product waste. rate and other problems, to achieve the effect of good shaping effect, reducing production cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

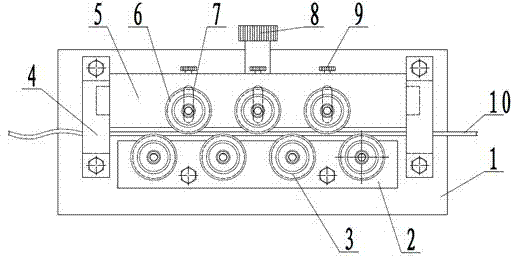

[0011] Depend on figure 1 It is known that a wire harness terminal crimping machine shaping mechanism consists of a frame 1, a fixed plate 2, a fixed bearing 3, a track 4, a movable plate 5, an adjustment bearing 6, a waist hole 7, a quick adjustment knob 8, a fine adjustment knob 9, cable 10, the fixed plate 2 is fixed on the frame 1, the fixed bearing 3 is fixed on the fixed plate 2, the adjusting bearing 6 is fixed on the movable plate 5, and the movable plate 5 is fixed together with the frame 1 through the track 4, so The bottom of the frame 1 described above is provided with a fixed plate 2, and the upper part is fixed with the movable plate 5 through the track 4, four rows of fixed bearings 3 are fixed on the horizontal line of the fixed plate 2, and three rows of adjusting bearings 6 are fixed on the horizontal line of the movable plate 5. The fixed bearing 3 and the adjusting bearing 6 are respectively provided with an upper shaping wheel and a lower shaping wheel, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com