An insulating cap for a high-current high-voltage circuit breaker

A high-voltage circuit breaker and insulating cap technology, which is applied to insulators, air switch parts, etc., can solve the problems of insufficient insulation distance of the insulating cylinder, unable to meet the requirements of use, low insulation capacity, etc., to improve the insulation effect, good insulation performance, The effect of increasing the discharge distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

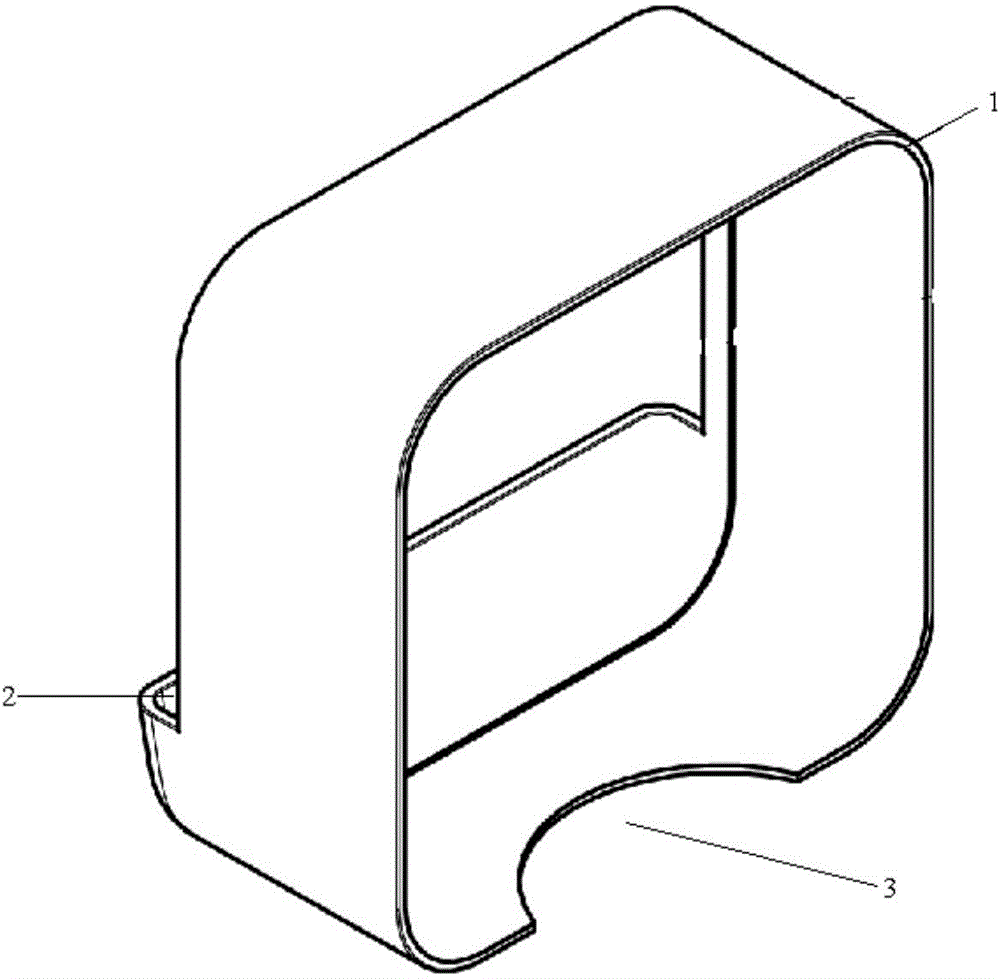

[0010] Embodiment 1: as figure 1 As shown, an insulating cap of a high-current high-voltage circuit breaker is prepared by heating epoxy resin solid material to a liquid state and injecting it into a mold. It is a square hollow cap, and the inner wall of the hollow cap is provided with an insulating layer 1. The lower side of the hollow cap is provided with a limit step 2, an opening is opened on the hollow cap on the upper part of the limit step 2, and a card slot 3 is provided on the opposite side of the limit step 2, the thickness of the insulating layer 1 is 1mm, and the top of the insulating layer 1 The angle of inclination between the surface and the horizontal plane is 15°, and the slot 3 is a semicircular structure that is recessed to the inside of the hollow cap, and its diameter is the same as the outer diameter of the target insulating cylinder.

[0011] There is a large opening on the upper part of the insulating cap to facilitate heat dissipation; in order to incr...

Embodiment 2

[0013] Example 2: An insulating cap for a high-current high-voltage circuit breaker is prepared by heating epoxy resin solid material to a liquid state and injecting it into a mold. It is a square hollow cap, and the inner wall of the hollow cap is provided with an insulating layer 1 , the inner lower side of the hollow cap is provided with a limit step 2, an opening is opened on the hollow cap on the upper part of the limit step 2, and a card slot 3 is provided on the opposite side of the limit step 2, the thickness of the insulating layer 1 is 2 mm, and the insulating layer 1 The inclination angle between the top surface and the horizontal plane is 18°, and the clamping groove 3 is a hollow semicircular structure recessed to the inside of the hollow cap, and its diameter is the same as the outer diameter of the target insulating cylinder.

Embodiment 3

[0014] Example 3: An insulating cap for a high-current high-voltage circuit breaker is prepared by heating epoxy resin solid material to a liquid state and injecting it into a mold. It is a square hollow cap, and the inner wall of the hollow cap is provided with an insulating layer 1 , the inner lower side of the hollow cap is provided with a limit step 2, an opening is opened on the hollow cap at the upper part of the limit step 2, and a card slot 3 is provided on the opposite side of the limit step 2, the thickness of the insulating layer 1 is 3mm, and the insulating layer 1 The inclination angle between the top surface and the horizontal plane is 20°, and the clamping groove 3 is a hollow semicircular structure recessed to the inside of the hollow cap, and its diameter is the same as the outer diameter of the target insulating cylinder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com