Method for simulating influence of heating technology on premelting and melting of crystal boundaries by aid of crystal phase-field process

A technology of crystal phase field and simulated heating, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve problems such as unquantifiable research on pre-melted layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

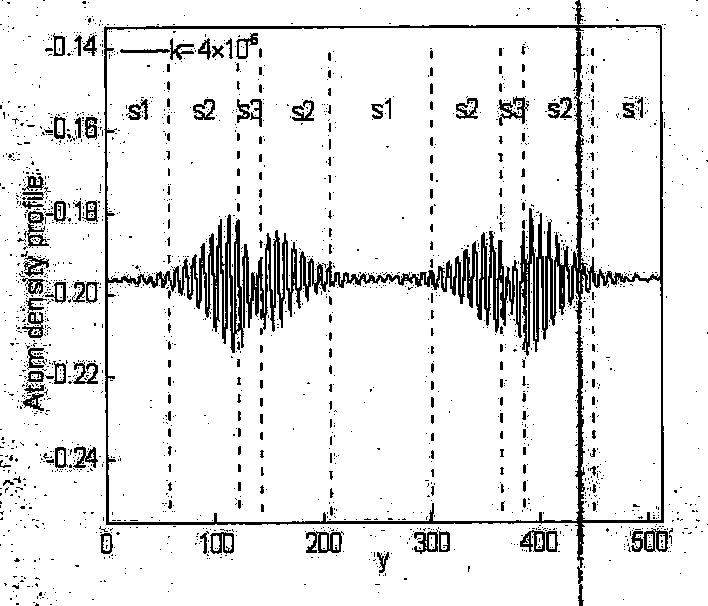

[0042] A method for simulating the influence of a heating process on grain boundary premelting and melting by using a crystal phase field method, specifically comprising the following steps:

[0043] (1) Establish the crystal phase field model:

[0044] The crystal phase field model is constructed based on the idea of the traditional phase field method, and the periodic function form is introduced into the model. The order parameter adopts the periodic local time-averaged atomic density. Here, the density is written in a dimensionless form, the simplest dimensionless free The energy functional equation can be written as

[0045] F = ∫ d r → { ρ 2 [ - ϵ + ( ▿ 2 + 1 ) 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com