Mud shale brittle nature experimental device and experimental analysis method thereof

An experimental device and mud shale technology, which is applied in the direction of measuring device, analysis material, strength characteristics, etc., can solve the problems affecting the analysis accuracy, sample residue, large difference, etc., and achieve short test period, easy operation and easy application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

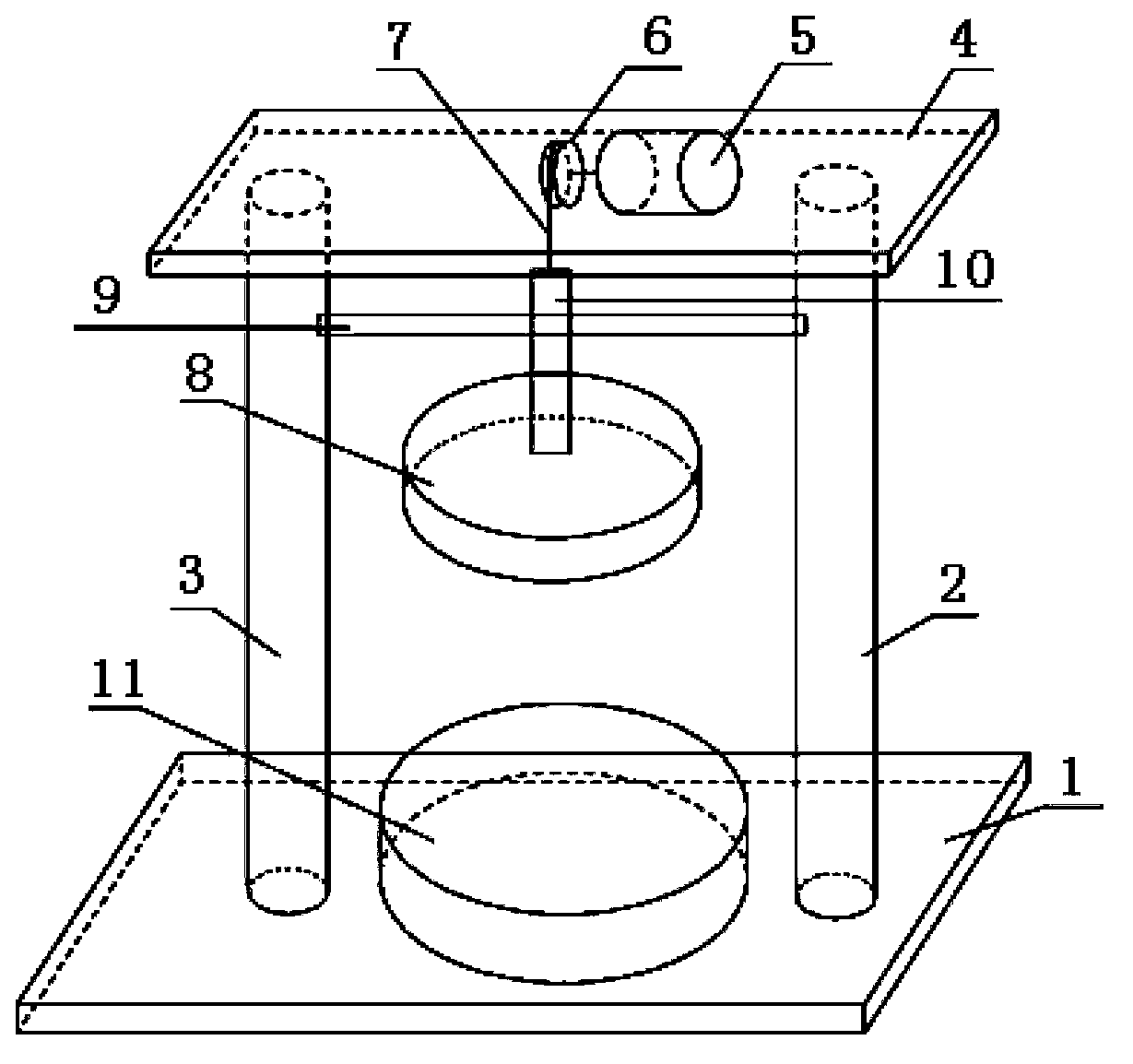

[0090] Such as image 3 , Figure 4 As shown, an experimental device for the brittleness of shale, including a base 1, a first guide column 2, a second guide column 3, a top plate 4, a motor 5, a pulley 6, a traction rope 7, a drop weight 8, and a horizontal guide Rod 9, longitudinal guide rod 10 and sample tray 11.

[0091] The base 1 is a steel plate with a thickness of 2 cm, and the center of the base 1 is provided with a groove matching the outer diameter of the sample disk 11. The groove is a circular groove with a depth of 3 mm, and the sample disk 11 is embedded in the groove. The material of the sample plate 11 is steel, and a shale sample is placed in the center thereof.

[0092] The drop hammer 8 is a steel cylinder with a flat bottom, which is arranged directly above the sample pan 11, and the quality of the drop hammer 8 is 5 kg.

[0093] The first guide column 2 and the second guide column 3 are vertically arranged on the base 1 respectively, and the side walls...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com