A signal processing method for non-contact detection of rotating body

A signal processing and signal detection technology, applied in the measurement of the geometric parameters of the contour of a rotating body, and the analysis and processing of the contour signal of a rotating body by a computer, which can solve the problems of large error, slow measurement speed, and inaccurate measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below.

[0021] The invention provides a processing method for a non-contact detection signal aiming at the outline size of a rotating body. The overall input of this method is the matrix signal collected by the optical sensor, and the overall output is various geometric parameters of the profile of the measured object.

[0022] The signal processing process is divided into seven steps, which are described in detail below

[0023] In the first step S1, the original signal is obtained from the optical sensor. The type of the original signal is a numeric matrix, and each element in the matrix is a non-negative integer representing the signal strength at that location. Typically, the target object location has a strong signal and the background has a weak signal.

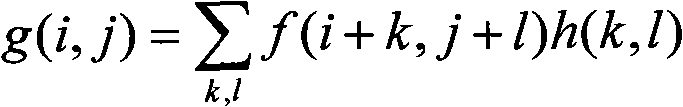

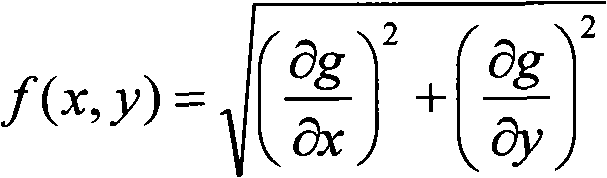

[0024] In the second step S2, each element value in the original signal matrix is mapped according to certain rules. The mapping rules described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com