freezer

A freezer and cabinet shell technology is applied in the field of frost blocking devices for freezers. Effects of frost cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

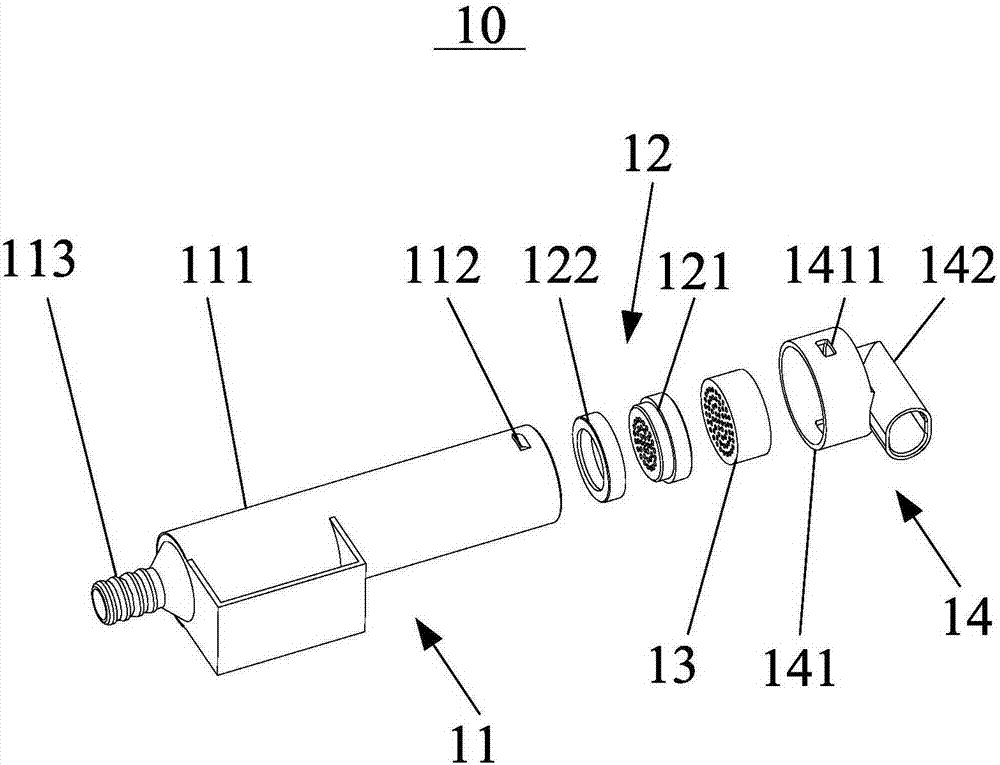

[0038] According to a preferred embodiment of the present invention, Figure 1~Figure 9 Represents a refrigerator, the refrigerator has a frost-proof device 1, and the frost-proof device 1 includes: a dehumidification pipe 10, a cabinet mouth connector 20, a cabinet shell connector 30, and a device connected between the cabinet mouth connector 20 and the cabinet shell connector 30 The hose 40.

[0039] The dehumidification pipe 10 is located in the foam layer, and includes a pipe body 11, a dehumidification filter screen 12, a filter screen 13 and a pipe cover 14. The pipe body 11 is a long cylindrical shape penetrating along the axial direction, and includes a main body 111 with a larger diameter and a One end of the main body 111 is continuously provided with an externally threaded pipe 113 with a smaller diameter than the main body 111 protruding in the axial direction, and a pair of Protrusion 112.

[0040] The dehumidification filter screen 12 is arranged on the inner s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com