Electric water heater water boiling and anti-dry-heating control method

The technology of an electric water heater and a control method, which is applied to fluid heaters, lighting and heating equipment, etc., can solve the problems of increasing the cost of heating elements, accelerated oxidation of the surface of the heating plate, and high production costs, and achieve the effect of eliminating dry burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

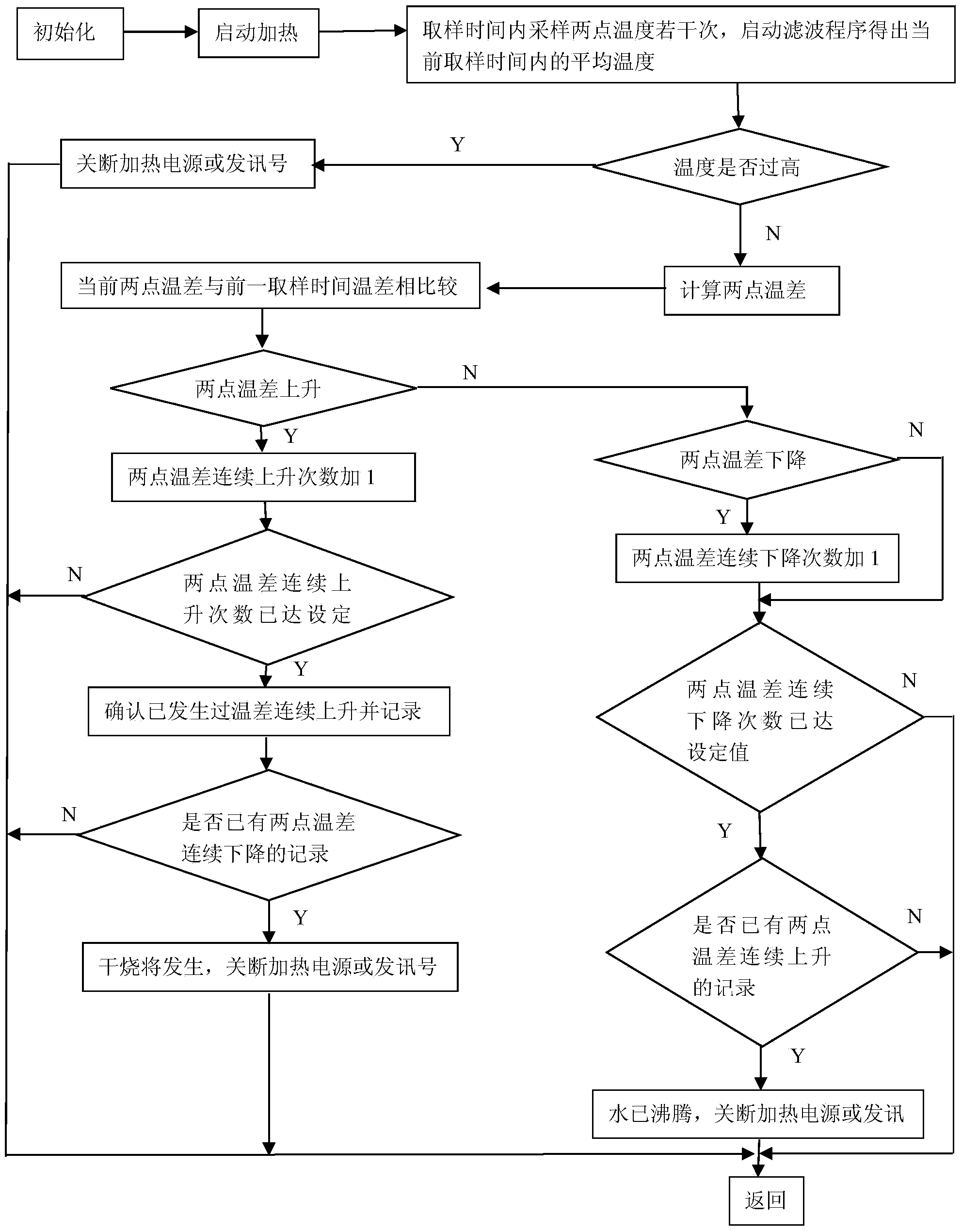

Image

Examples

Embodiment 1

[0035]Embodiment 1: An electronic kettle is equipped with a control circuit board with a microprocessor chip as the core component. Two temperature sensors are installed on the back side of the chassis of the heating plate, and one of them is installed on the heating plate. The edge of the plate (it can also be installed in the center of the heating plate), this point is in the early stage of the end of water boiling, the temperature is lower, and the other is installed near the middle of the heating plate heating wire (but not close to it), this point is at the end of the water In the early stage of boiling, the temperature is higher. (in order to reduce the influence of kettle inclination, two temperature sensors are preferably contained on the same diameter position of the garden type heating plate). After power-on and initialization, the microprocessor detects the temperature of two points through the temperature sensor, and can calculate the average value per second after...

Embodiment 2

[0036] Embodiment two: an electronic water kettle is equipped with a control circuit board with a microprocessor as the core component, a temperature sensor is contained in the middle part of the heating wire near the heating plate (but not next to it), and another temperature sensor is placed in the water. Compared with the first embodiment, this embodiment only has a different placement position of a temperature sensor, and the judging state and control process and method are the same as the first embodiment.

Embodiment 3

[0037] Embodiment 3: The electric steamer of the pan bottom structure, the bottom of the pan and the contact part of the water are flat, unlike some steamers with protrusions on the bottom (the protrusions are embedded with temperature sensors to detect dry burning), nor are they like some There is a temperature sensor at the bottom of the electric water heater and the like that is in contact with the water. The temperature sensor of this electric steamer is placed on the backside of the bottom of the heating plate, one of which is installed near the opening of the heating wire near the edge of the heating plate. This point is in the early stage of water boiling, and the temperature is low, and the other is installed near the middle of the heating wire of the heating plate. (But not in contact with the heating wire), this point is at the early stage of water boiling, and the temperature is higher. Likewise, a control circuit board with a microprocessor chip as the core compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com