Composite steel pipe

A steel pipe and pipe body technology, applied in the field of pipeline conveying equipment, can solve the problems of short life, high cost and low strength, and achieve the effects of long life, cost saving and overall performance improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

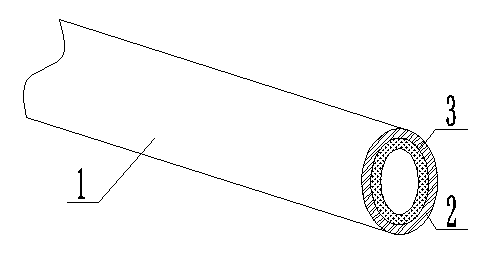

[0010] Such as figure 1 It is a structural schematic diagram of the present invention, a synthetic steel pipe, including a pipe body 1, and the pipe body 1 is composed of a stainless steel layer 2 and a PE resin layer 3. The stainless steel layer 2 is located on the outer layer of the pipe body 1, and the PE resin layer 3 is located on the inner layer of the pipe body 1.

[0011] The pipe body 1 is designed as a composite structure of two materials. The stainless steel layer 2 is located on the outer layer of the pipe body 1, and the PE resin layer 2 is located on the inner layer of the pipe body 1. The two materials complement each other, which not only retains the excellent characteristics of the stainless steel layer 2, but also The advantages of the PE resin layer 3 in anti-corrosion, anti-aging, and long life are brought into play, which not only improves the overall performance of the pipe body 1, but also saves costs, and meets the needs of the working environment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com