Cleaning type anti-mixing butterfly valve with single butterfly plate

A butterfly plate and butterfly valve technology, applied in the field of single butterfly plate cleaning type anti-mixing butterfly valve, can solve the problems of sealing leakage, secondary pollution, pollution and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

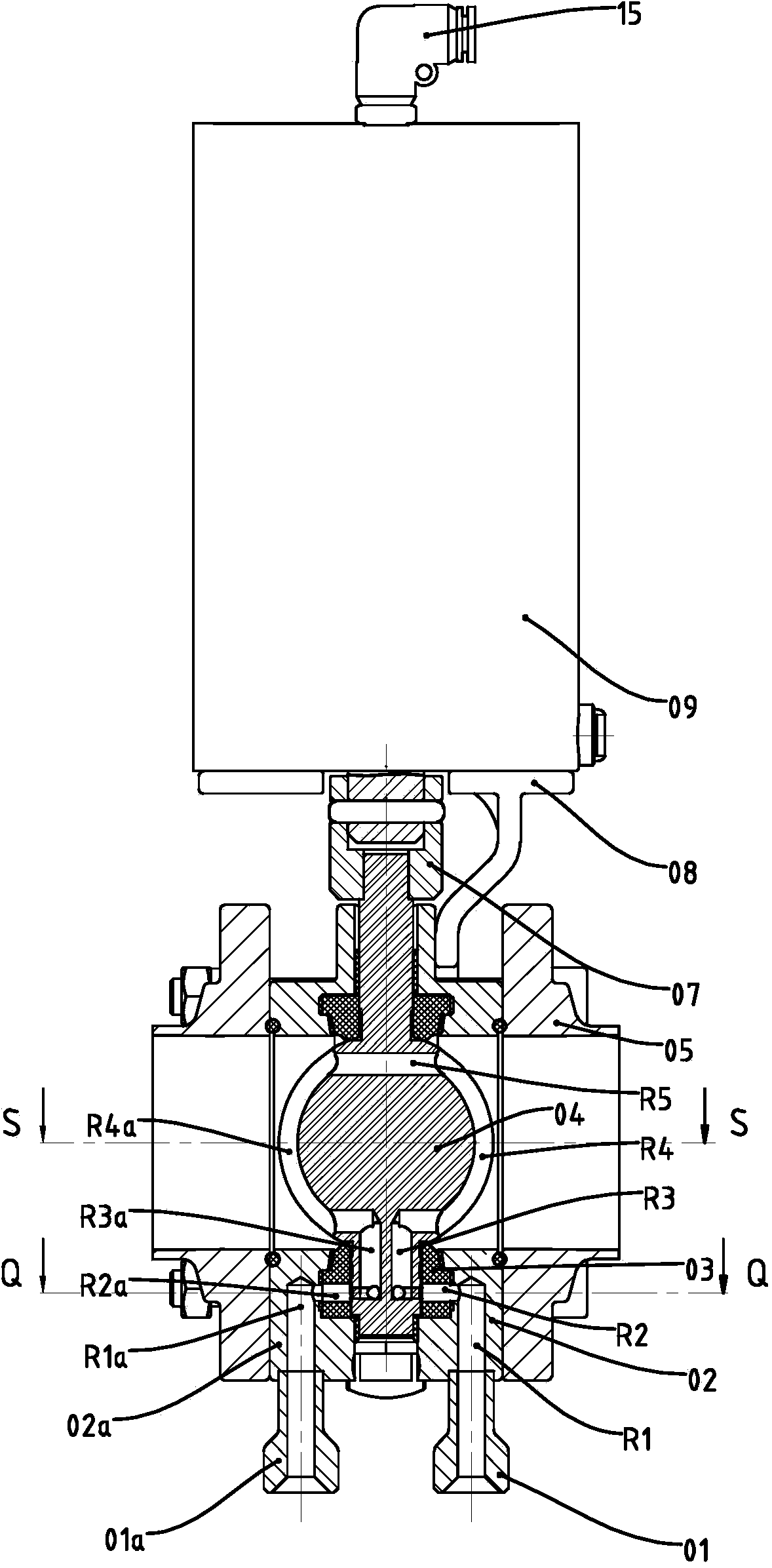

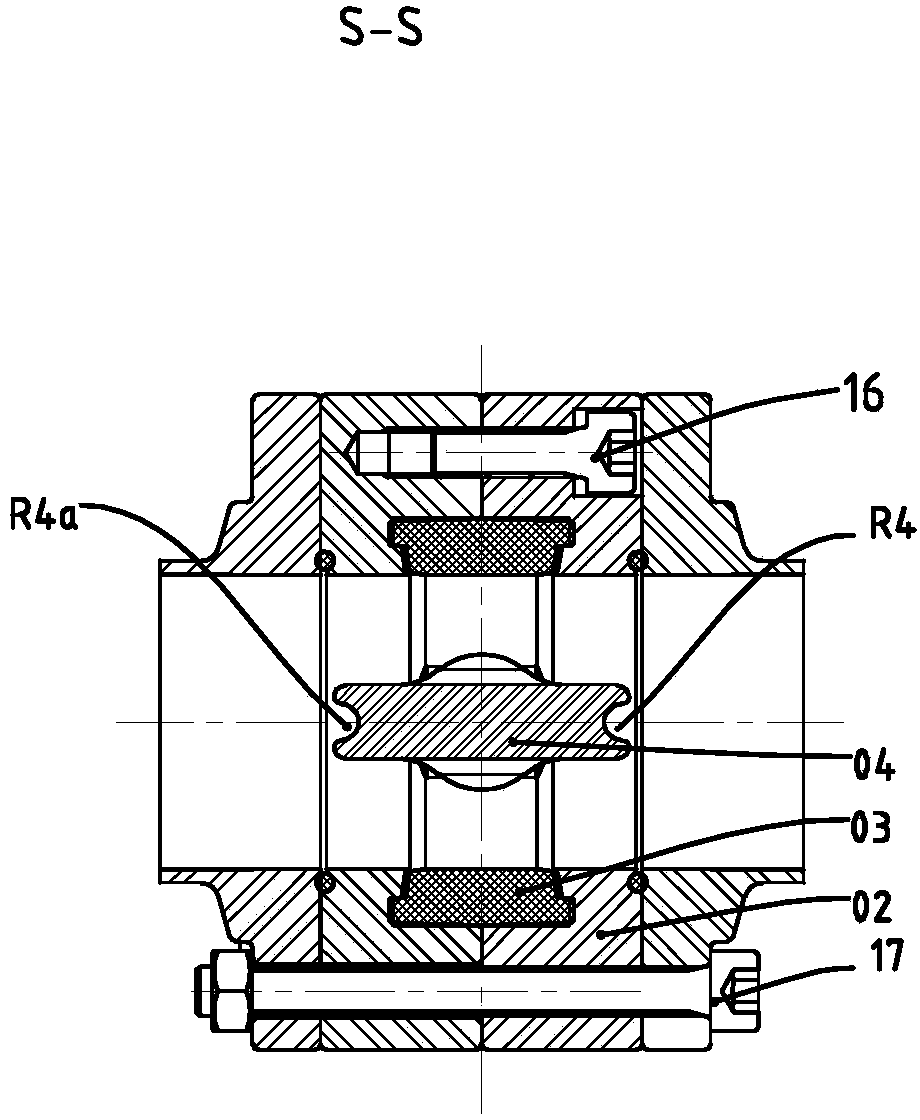

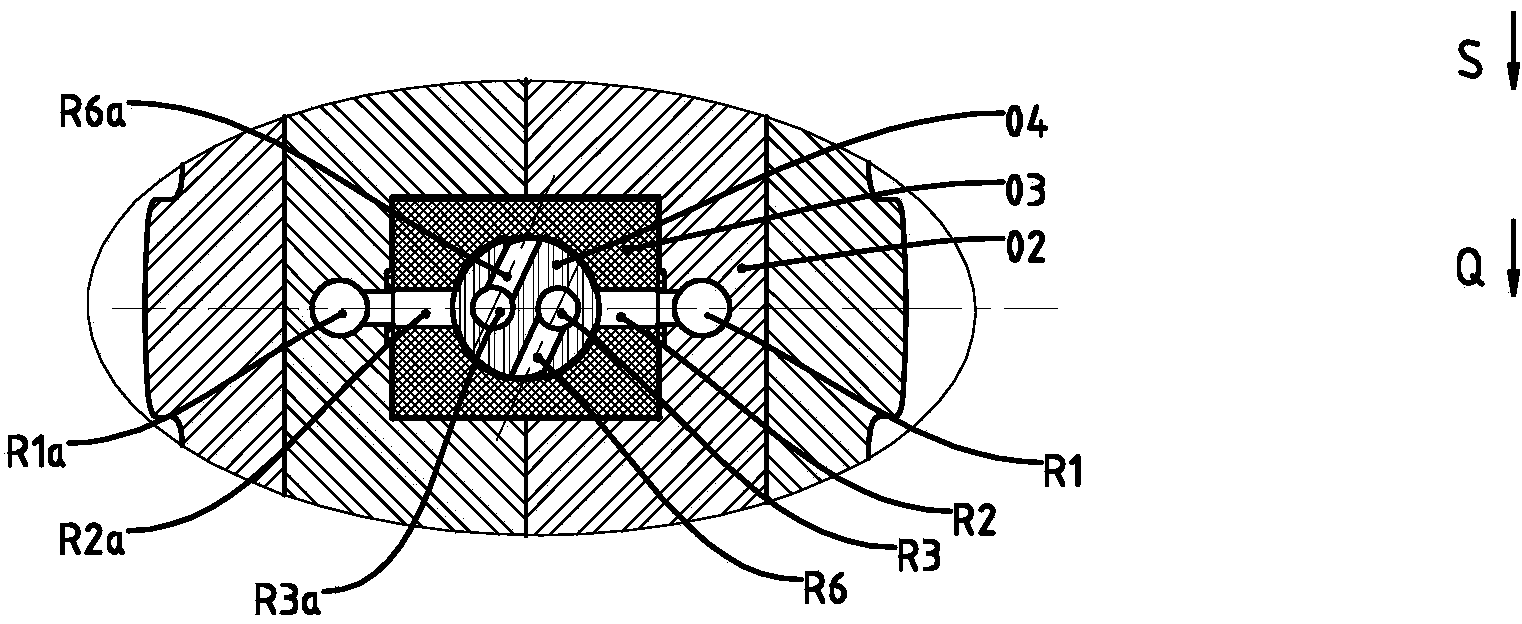

[0022] The present invention is mainly composed of a butterfly plate 04, two valve bodies 02, 02a, a sealing ring 03, an inlet cleaning pipe 01 and an outlet cleaning pipe 01a, the first bolt 16 fixes the upper device together, and the second bolt 17 connects the upper The device and the connecting body 05 are fixed together, and the two connecting bodies 05 only play the role of connecting pipes in this device. The connecting shaft 07 drives the butterfly plate 04 with the energy from the cylinder 09, and the pneumatic bracket 08 is used to fix the cylinder Figure 1.1-Figure 1.3 . There are arc-shaped grooves on the outer edge of the single butterfly plate 4 of the anti-mixing butterfly valve. R6a connection, so that the butterfly plate itself forms a channel. Once the channel forms a closed condition, it will form a circulation channel, and the cleaning fluid will pass through it for cleaning. Figure 3.1-Figure 3.5 .

[0023] The sealing ring 03 of the anti-mixing butter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com