Thread anti-bending mechanism

An anti-bending and threading technology, which is applied in the direction of threaded fasteners, nuts, bolts, etc., can solve problems such as uneven axial load distribution, cylindrical fatigue, fracture, etc., achieve flexible and controllable position and degree, and reduce bending , Weaken the effect of the force on the annular surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

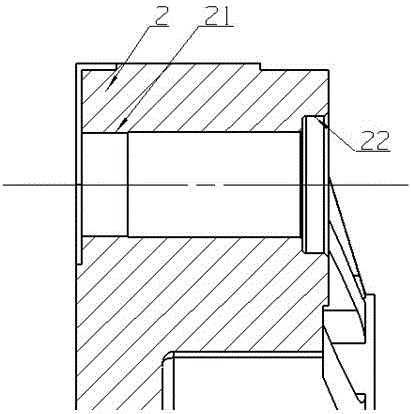

[0026] The present invention will be further described below with reference to the embodiments of the drawings, taking the threaded anti-bending mechanism as a pull rod mechanism as an example, and applying the pull rod mechanism to an injection molding machine head template.

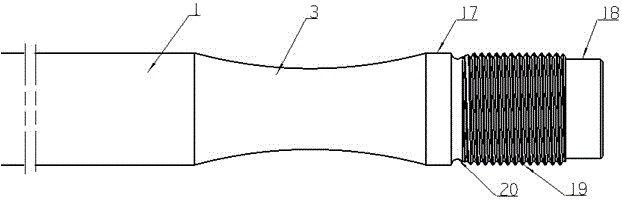

[0027] like figure 1 As shown, a threaded section 19 is provided at the head of the tie rod 1 of the injection molding machine, and a fulcrum section 17 and a fulcrum section 18 are provided in the front and rear regions adjacent to the threaded section 19 .

[0028] An undercut 20 is also provided between the above-mentioned fulcrum section 17 and the thread section 19 to facilitate machining.

[0029] The above-mentioned fulcrum section 17 , fulcrum section 18 , undercut 20 and thread section 19 are coaxial.

[0030] An unloading groove 3 is also provided on the tie rod 1, and the bending of the tie rod 1 is controlled by the shape and position.

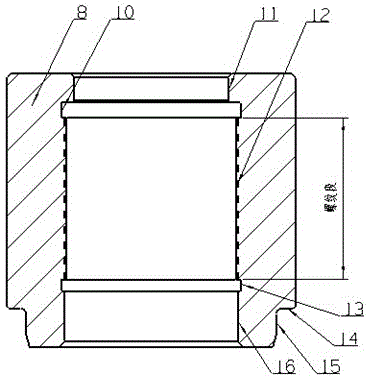

[0031] like figure 2 As shown, a support sleeve se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com