Booster for a hydraulic system

A technology of hydraulic system and booster device, applied in the direction of fluid pressure converter, mechanical equipment, etc., can solve the problems of insufficient use of oil, consumption, increase system volume and cost, etc., achieve convenient structure, reduce cost, Volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

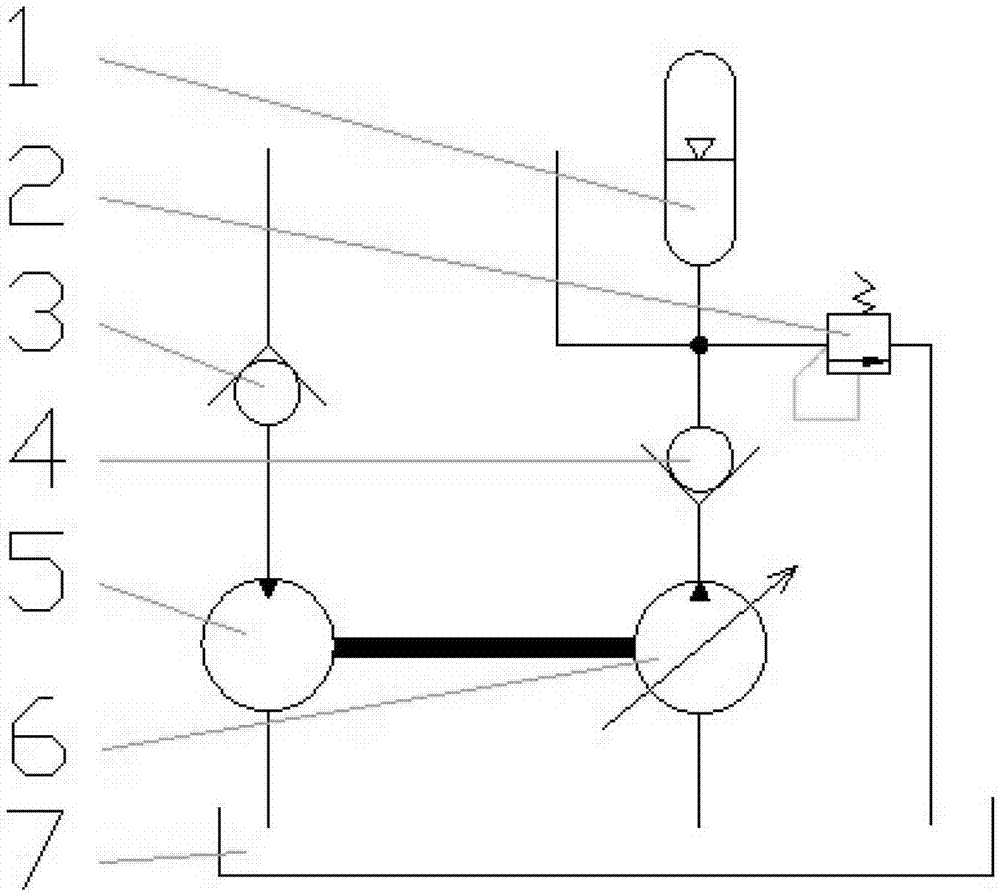

[0012] The invention discloses an energy recovery and boosting device for a hydraulic system, which includes a hydraulic motor 5, a hydraulic pump 6, an oil tank 7 and an accumulator 1. The oil flows from the pipeline to the hydraulic motor to drive the hydraulic motor to rotate; After absorbing the oil, pump the oil to the accumulator, which is characterized in that the accumulator 1 is pre-charged with a certain pressure, the output shaft of the hydraulic motor is connected with the input shaft of the hydraulic pump, and the rotation of the hydraulic motor drives the rotation of the hydraulic pump , the displacement of the hydraulic motor is greater than the displacement of the hydraulic pump, so that the low-pressure liquid flow from the pipeline drives the small-displacement hydraulic pump through the large-displacement hydraulic motor, realizing the conversion of low pressure to high pressure, and conversion to high pressure The oil is stored in the accumulator. Therefore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com