Equipment for processing synthetic silk threads

A technology of equipment and silk thread, applied in the field of equipment for processing synthetic silk thread, can solve the problem of time-consuming operation process, and achieve the effect of avoiding insulating materials and avoiding heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

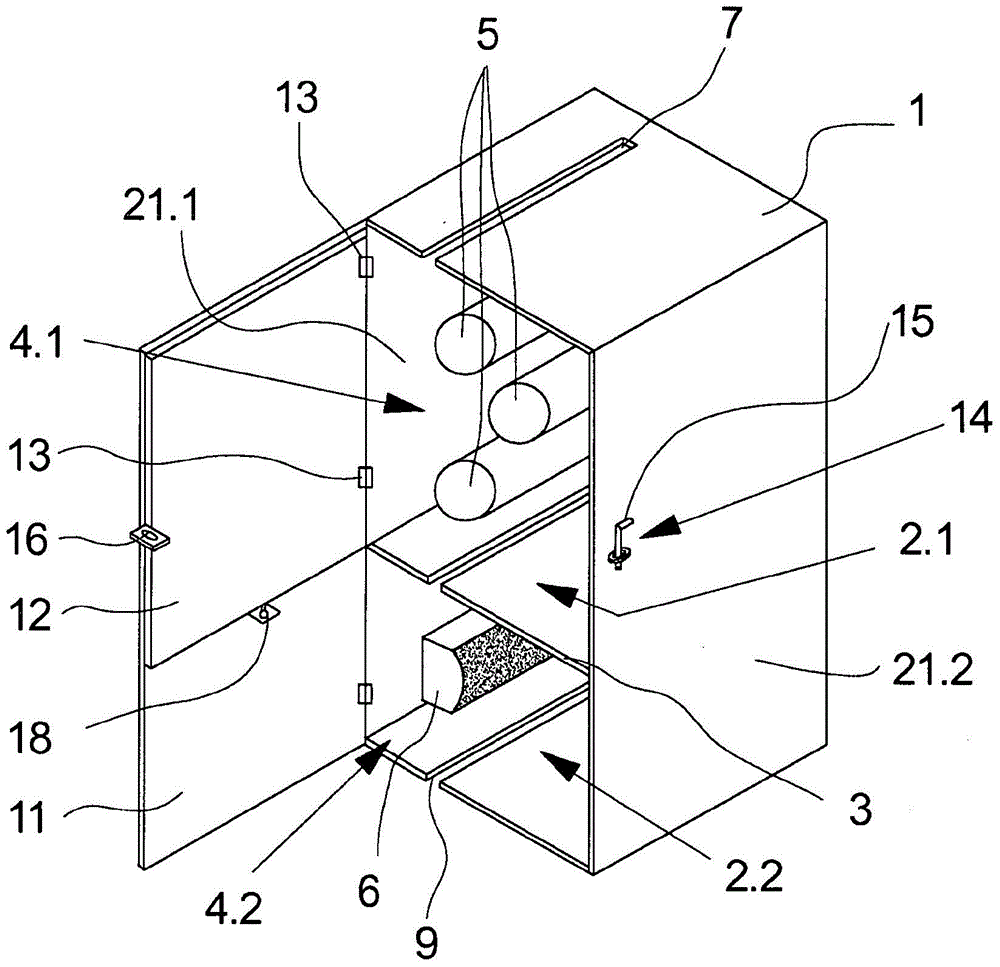

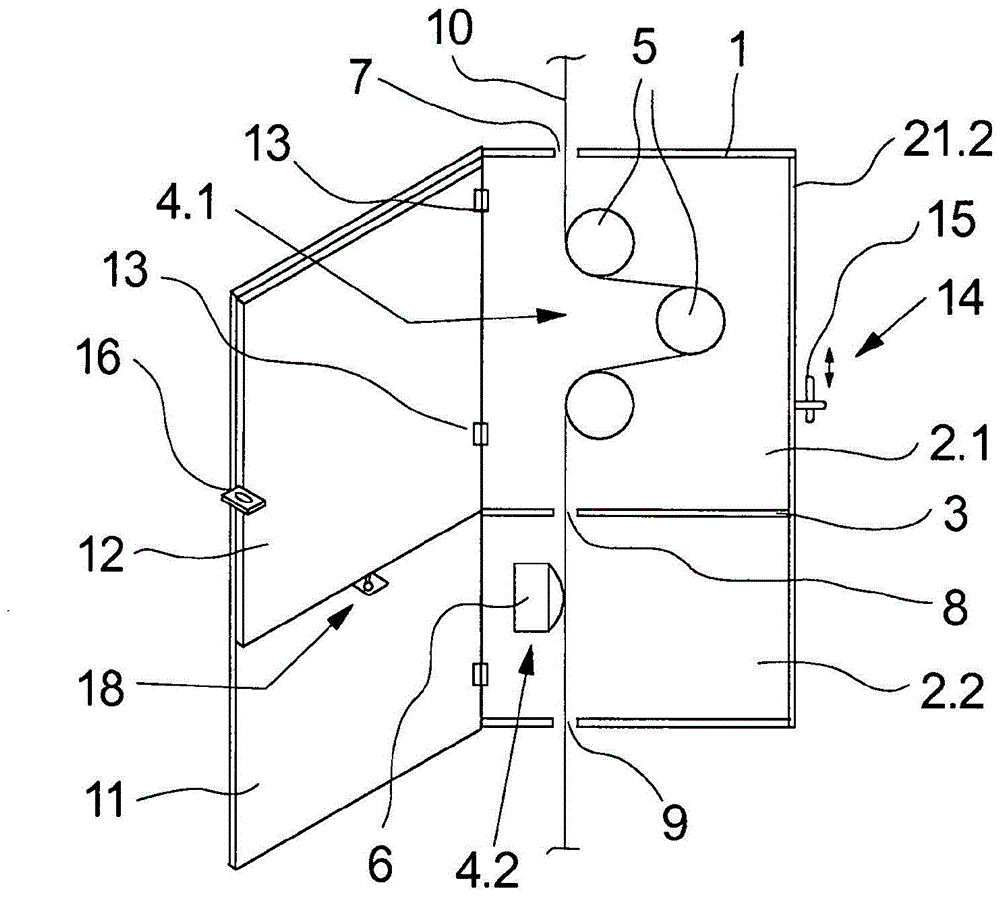

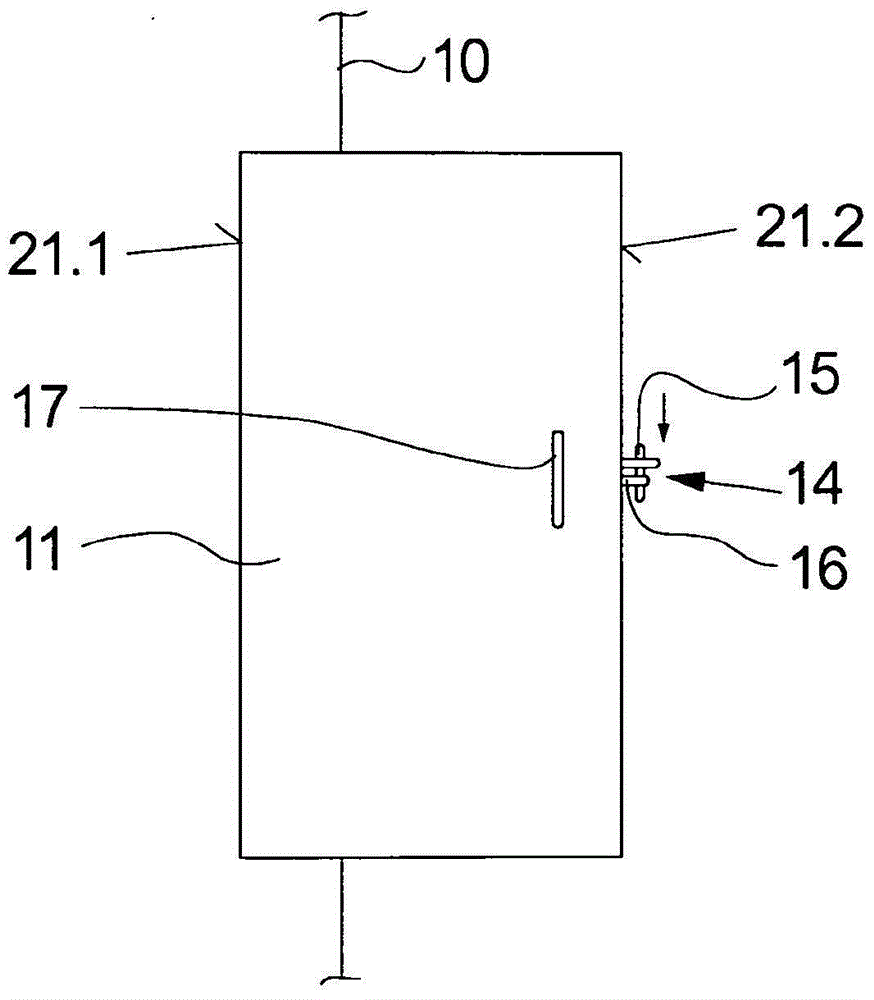

[0020] exist Figures 1 to 4 In , embodiments of the device according to the invention are shown in different views and operating situations. figure 1 An embodiment of the device according to the invention is shown perspectively in a stationary state. exist Figure 2 to Figure 4 In the figure, the embodiment is shown in different operating situations in front view. The following descriptions apply to all figures unless one of them is explicitly referred to.

[0021] This exemplary embodiment has a housing 1 which forms an upper treatment chamber 2.1 and a lower treatment chamber 2.2. In each of the treatment chambers 2.1 and 2.2, respectively, treatment devices 4.1 and 4.2 are provided for treatment of one or more synthetic threads. The upper treatment chamber 2.1 has a treatment device 4.1 formed by a plurality of heated godets 5. FIG. The heated godet 5 is driven, wherein the drive is arranged outside the housing 1 on the rear side, not shown here.

[0022] The treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com