Premixing mixer and finished product warehouse cleaning method

A technology for finished product bins and mixers, applied to mixers, mixers with rotating stirring devices, chemical instruments and methods, etc., can solve problems such as sudden operation of mixer blades, personnel consumption, worker injuries, etc., to avoid consumption, increase production efficiency, and save production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings and examples.

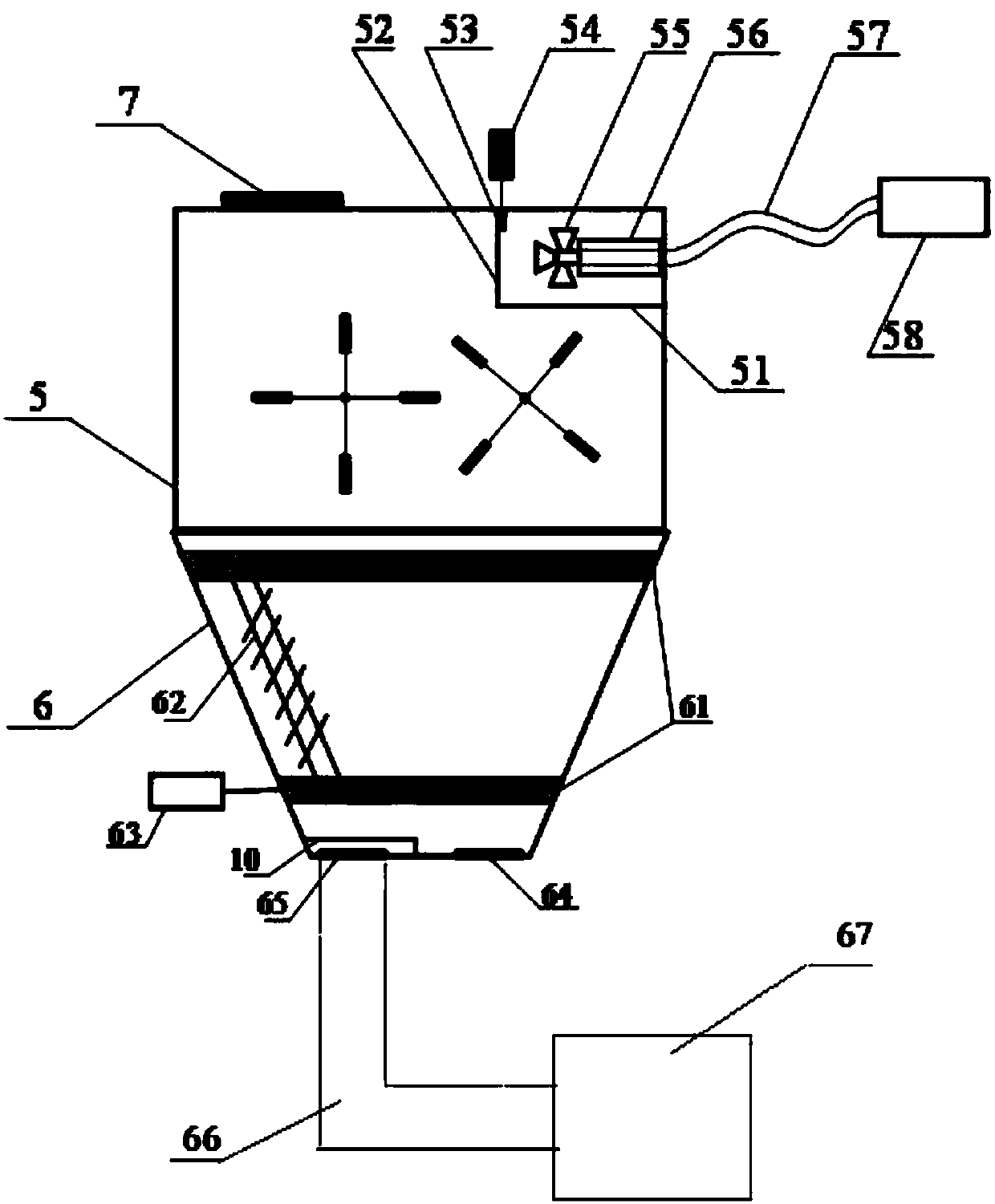

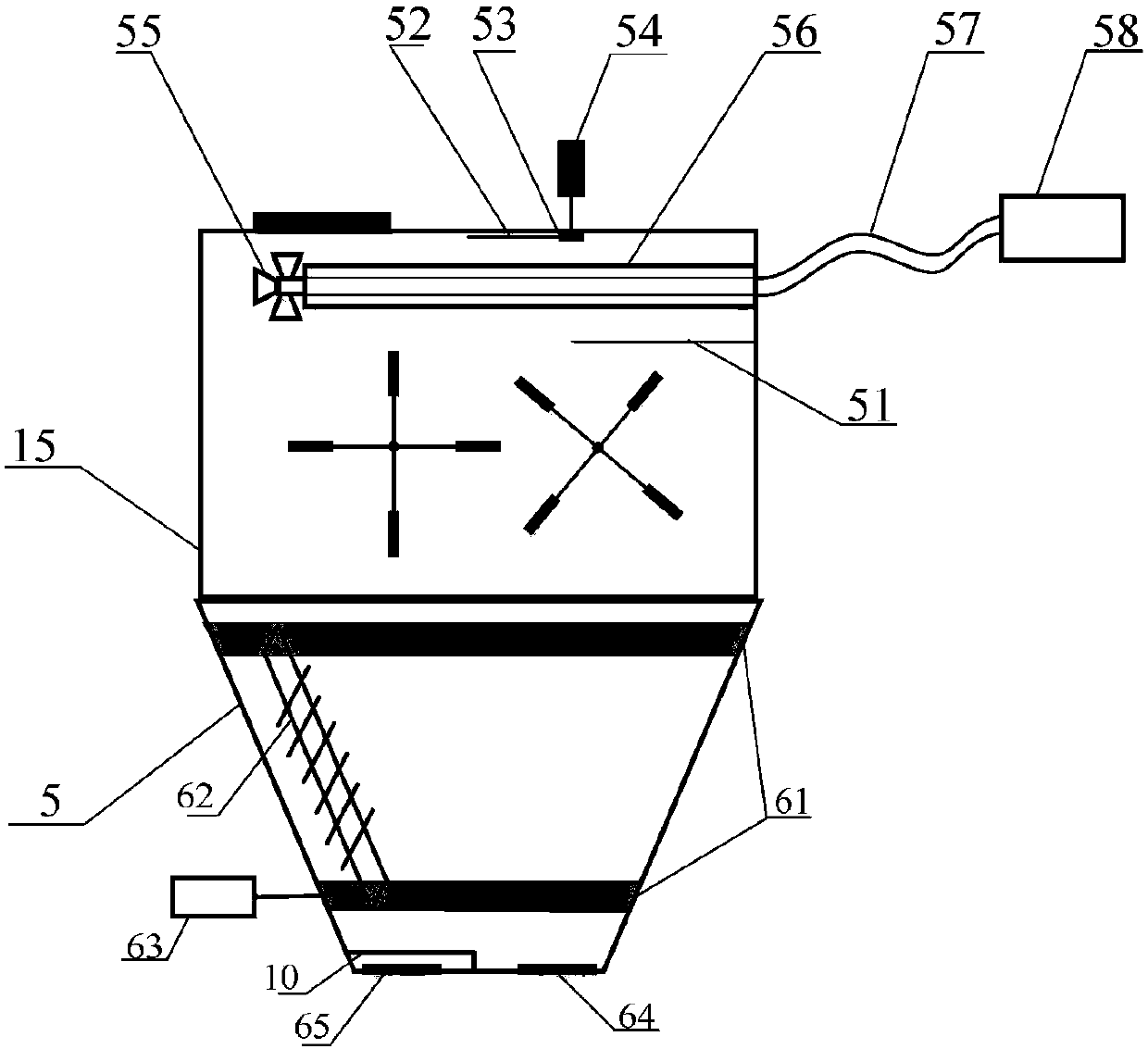

[0020] The invention provides a cleaning method for a premix mixer and a finished product bin, see figure 1 and figure 2 , the premix mixer and the finished product bin cleaning device adopted in the present invention, a warehouse is provided in the mixer, and the warehouse is composed of an airtight cover 51 and part of the side wall of the mixer 5, and the airtight cover 51 and the mixer The side walls are fixedly connected, the airtight cover 51 is provided with a door 52, and the door 52 is provided with a door opening and closing controller 53, and the door opening and closing controller 53 realizes opening of the door 52 under the control of the control motor 54 and closing; the premixed material enters the mixer 5 through the mixing inlet 7, and one end of a hollow telescopic bracket 56 is fixed on a part of the side wall of the mixer 5, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com