Installation structure and method for accurately positioning tunnel arch wall lining buried type water-stop belt

A technology for accurate positioning and installation of structures, applied in tunnel linings, tunnels, shaft linings, etc., which can solve problems such as uneven exposed parts, different depths of embedded concrete, and easy water leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

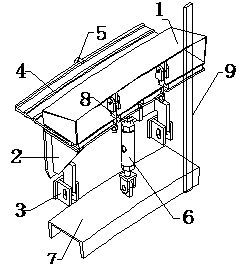

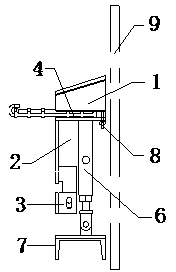

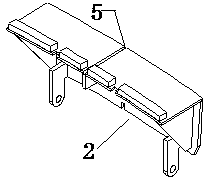

[0017] Embodiment of the present invention: a mid-buried waterstop 4 is set between the upper mold 1 and the lower mold 2, and a steel bar clip 5 is set at the bottom of the mid-buried waterstop 4; a twisted screw 8 is set on the lower edge of the upper mold 1, and The buried waterstop 4 between the mold 1 and the lower mold 2 is clamped and fixed by the twisted screw 8, the middle part of the lower mold 2 is provided with a screw 6, the lower edge of both sides is provided with a winch 3, and the support channel steel 7 and Support with screw mandrel 6 in the middle of lower die 2 .

[0018] The winch 3 and the support channel steel 7 are welded with the steel end dies of the two lining trolleys respectively.

[0019] Support channel steel 7 and upper mold 1, lower mold 2 outer edges adopt wooden formwork inserting plate 9 to reinforce.

[0020] The upper mold 1 is a trapezoidal steel mold, and the lower mold 2 is an L-shaped steel mold

[0021] The installation process of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com