Method for slowing longwall mining pressure appearance of shallow coal seam below gully

A gully and coal seam technology, applied in underground mining, surface mining, special mining, etc., can solve the problems of poor safety, high cost, affecting mine safety production, etc., and achieve the effect of strong applicability, improved recovery rate, and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

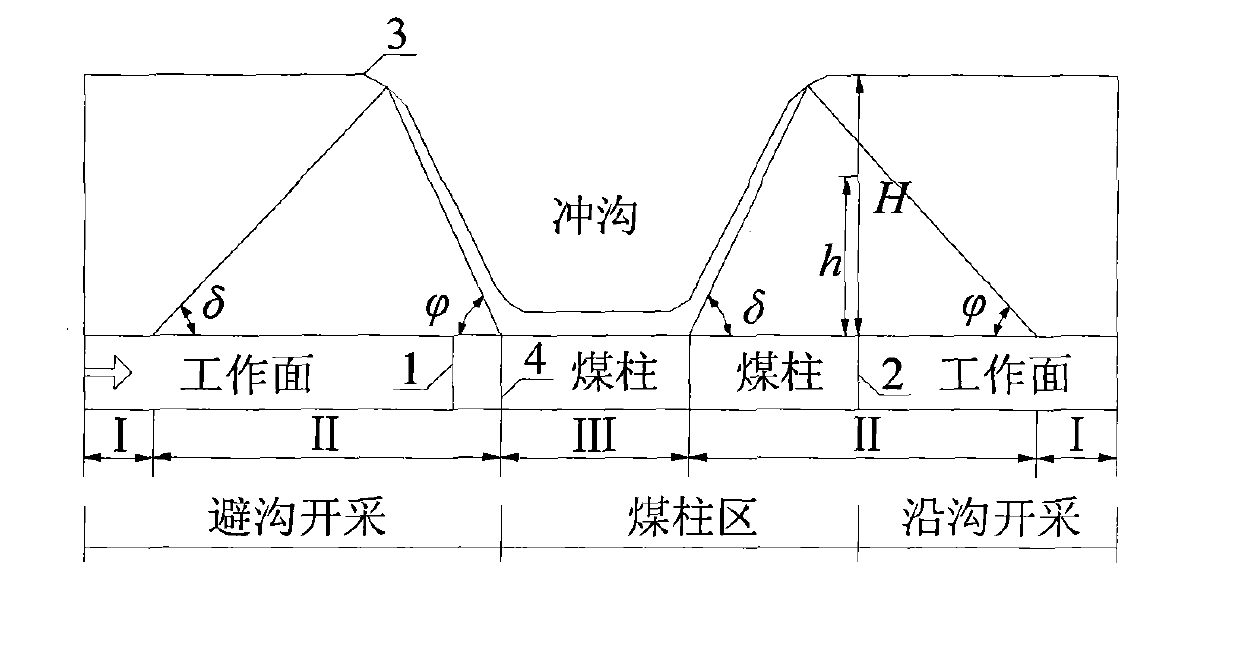

[0012] During the mining deployment, in order to reduce or avoid the impact of gully slope activities on mining, the position of the stop production line of the working face and the advancing direction of the working face are adjusted to realize mining in ditch avoidance or mining along the ditch.

[0013] Referring to the attached figure, when mining in trench avoidance, according to the mining influence angle (δ) and overburden fracture angle The area affected by gullies to mining is divided into no-influence area (I), impact area (II) and strongly-influence area (III). Mining influence angle (δ) and overlying rock breaking angle It can be obtained from the actual measurement data of each mining area. When the gully slope top (3) is affected by mining, the position of the working face is the dividing line between the unaffected area (I) and the affected area (II); the overburden breaking angle is determined by the gully slope top (3) , the corresponding position (4) is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com