On-line rapid transformation method of side column to center column in old industrial factory building with steel structure

A technology for industrial plants and steel structures, applied in building construction, building maintenance, construction, etc., can solve the problem that the capacity of the material storage area cannot meet the actual demand, etc., and achieve safe and reliable engineering quality, high speed, and low investment in plant renovation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

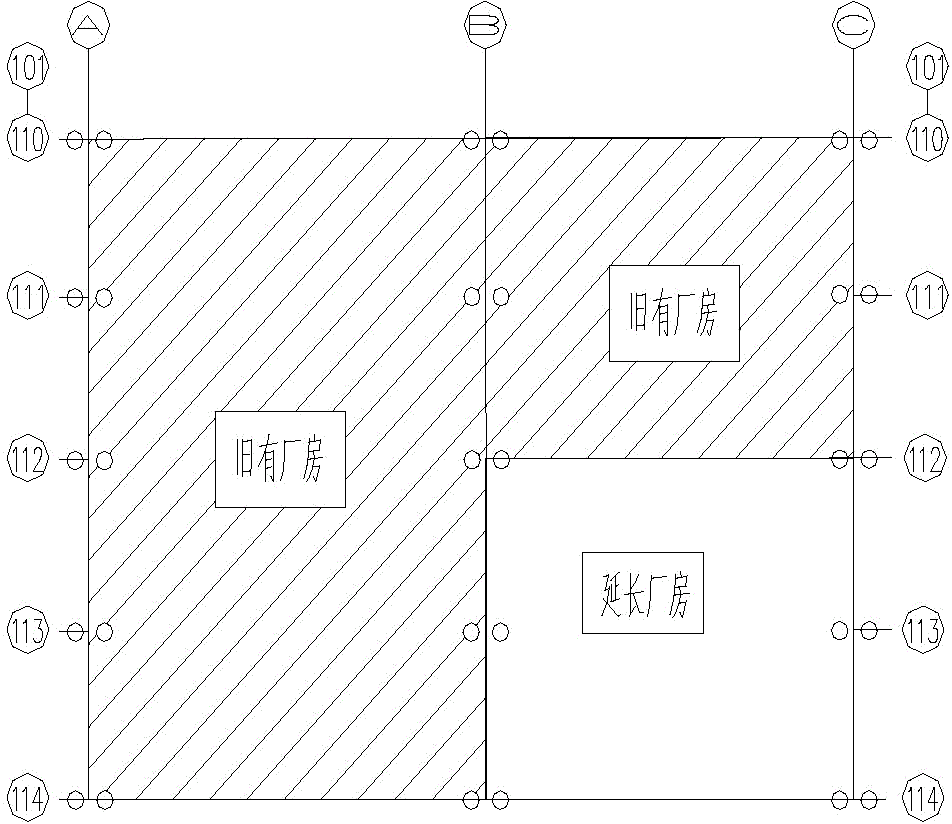

[0020] The column of the old steel structure industrial factory building is generally composed of upper and lower sections, the lower section is a double steel column, and the upper section is a single steel column. The upper section of the side column and the center column of the plant are different in structure, while the lower section is basically the same.

[0021] Middle column: L1=L2, that is, the distance between the center of the single steel column in the upper section and the center of the double steel column in the lower section is equal, which is a symmetrical structure. The centers of the driving beams on both sides coincide with the centers of the double steel columns respectively.

[0022] Side column: L1>L2, that is, the distance between the center of the single steel column in the upper section and the center of the double-row steel column i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com