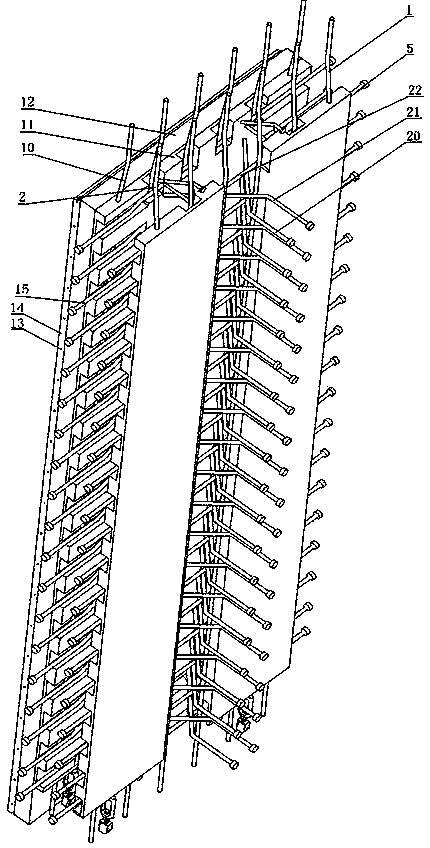

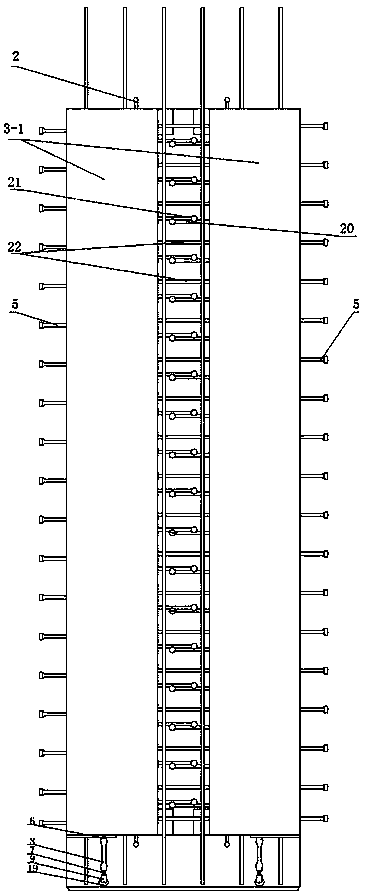

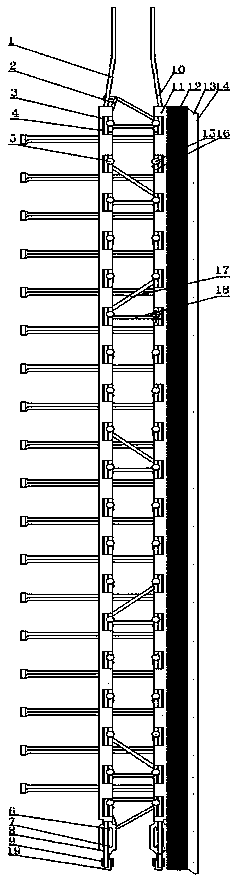

T-shaped assembling integral type shear wall external wall panel and construction method

A technology of shear walls and exterior wall panels, which is applied to building components, buildings, building structures, etc., can solve the problems of difficult installation and high cost, and achieve the effects of short construction period, simple steel bar connection, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Selected embodiments of the present invention are now explained with reference to the accompanying drawings. The following descriptions of the embodiments of the present invention disclosed by those skilled in the art are only exemplary and not intended to limit the solutions of the present invention.

[0030] A T-shaped assembled integral shear wall external wall panel is used for the connection between the external wall and the internal wall, including the external panel 14, the thermal insulation board 12 and the shear wall panel arranged in sequence; the external panel 14, the thermal insulation panel 12 and the shear wall panel The force wall panels are connected as a whole through a plurality of thermal break bridge connecting rods; the outer panel 14 is provided with a steel mesh layer 13; the shear wall panels are provided with an appropriate number of protruding connecting ribs from top to bottom, and the protruding connecting ribs protrude on the surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com