Prefabricated asphalt concrete steel bridge deck pavement structure and method

A technology for asphalt concrete and steel bridge decks, which is applied to coagulating pavements, bridges, bridge parts, etc., which are laid on site, and can solve the problems of insufficient shear resistance of concrete, easy to move, and low viscosity of ordinary modified asphalt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

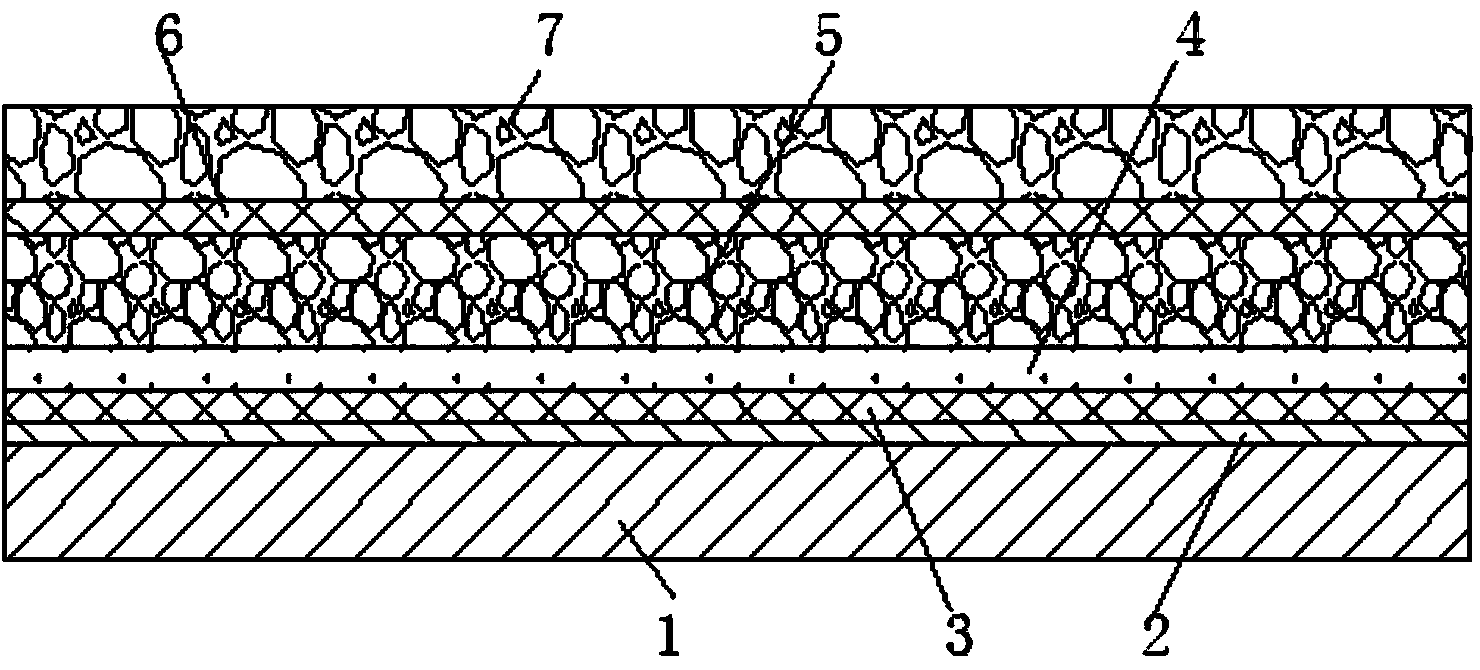

[0034] The prefabricated asphalt concrete steel bridge deck pavement structure of the present invention comprises: the anticorrosion layer 2 painted on the steel bridge deck 1; the waterproof layer 3 painted on the anticorrosion layer; the first adhesive layer sprayed on the waterproof layer 4; the asphalt concrete lower layer 5 laid on the first bonding layer; the second bonding layer 6 sprinkled on the asphalt concrete lower layer; and the prefabricated asphalt concrete laid on the second bonding layer Layer 7.

[0035] The underlayer of asphalt concrete may be a prefabricated underlayer of asphalt concrete or a conventional underlayer of asphalt concrete. The lower layer of conventional asphalt concrete is one of asphalt mastic concrete (SMA), cast asphalt concrete or epoxy asphalt concrete.

[0036] The "precast asphalt concrete upper course" and "precast asphalt concrete lower course" in the present invention refer to rollable asphalt pavements that are not produced on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com