Front drying system used for multi-cylinder long mesh paper machine

A technology of drying system and paper machine, applied in the field of pre-drying system, which can solve the problems of unfavorable paper, large paper stretching rate, low drying temperature, etc., achieve easy transfer and drying, improve the ability of paper, and improve sizing quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

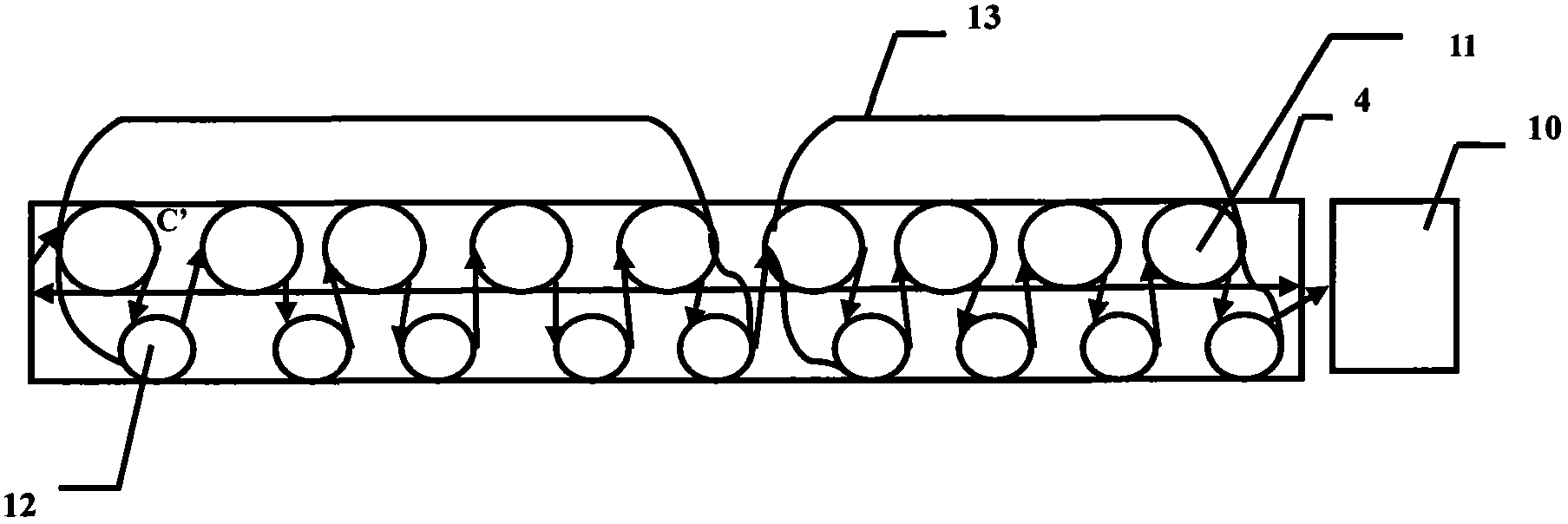

[0028] Such as figure 2 , 4 As shown, a kind of front drying system used on the fourdrinier multi-cylinder paper machine according to the present invention has a front drying part 4 and an enhanced drying device 10;

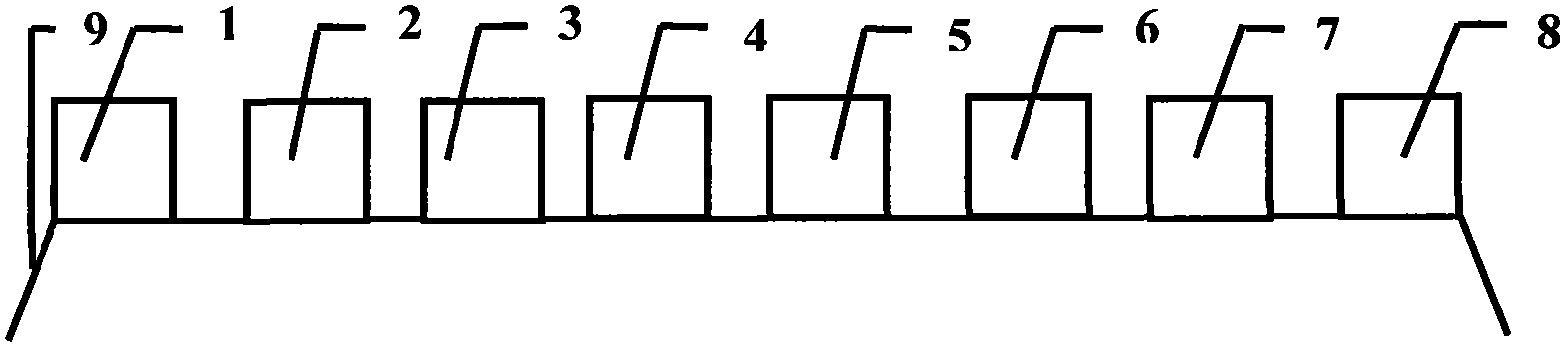

[0029] Such as image 3 , 4 As shown, the area of the front drying system is relatively larger than that of the traditional front drying system with the same width and speed;

[0030] The total number of drying cylinders 11 in the front drying section 4 is increased by 10%-50% compared with the total number of drying cylinders 11 in the traditional front drying section with the same width and speed;

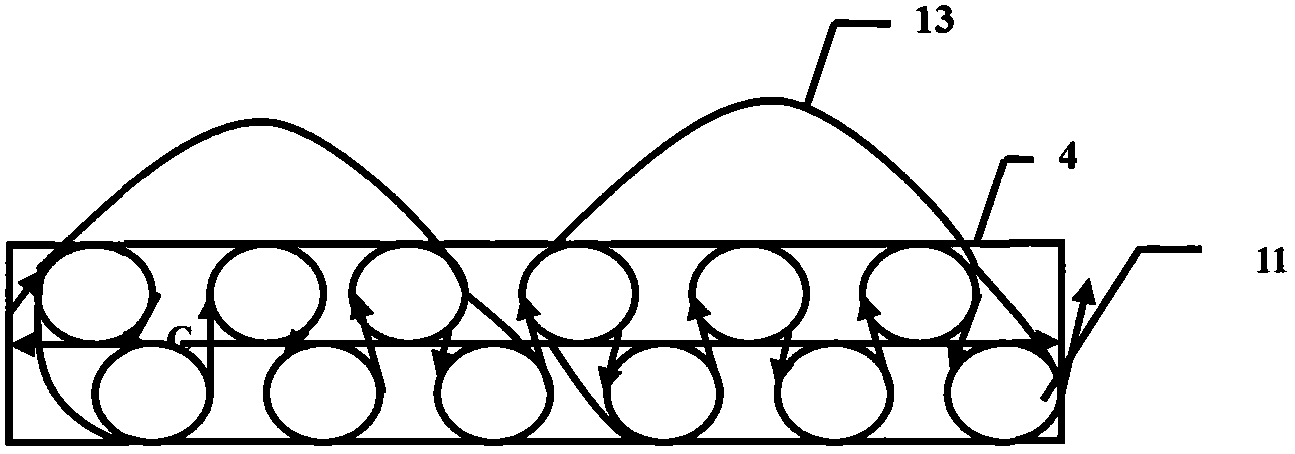

[0031] Such as figure 2 As shown, several drying cylinders 11 in the front drying section 4 are arranged in a single layer, and the lower part of each drying cylinder 11 cooperates with a Wacker cylinder 12 to enhance dehydration. The drying cylinders 11 are divided into groups of 3 to 6 ( figure 2 5 drying cylinders are listed as a group, and the front dr...

Embodiment 2

[0038] A pre-drying system used on a fourdrinier multi-cylinder paper machine according to the present invention has a pre-drying part 4, and the structure of the pre-drying part 4 is the same as that of the embodiment 1, without the enhanced drying device 10.

[0039] Compared with the traditional pre-drying system, the pre-drying system structure of the present invention solves the problem that the traditional pre-drying system is not suitable for producing high-filler pulp.

[0040] The content of the present invention is not limited to the content of this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com