Production method for high-elastic polyester yarn

A processing method and technology of polyester yarn, applied in textiles and papermaking, etc., can solve the problems of poor unwinding, severe end breakage, insufficient fabric elasticity, etc., and achieve the effects of improving curl shrinkage, weaving efficiency, and elasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

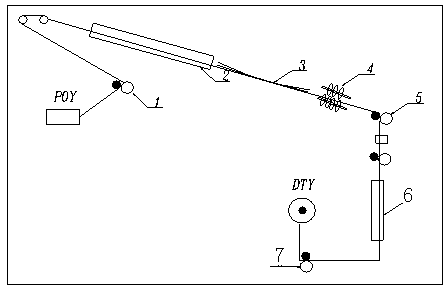

[0016] A processing method of high-elastic polyester yarn, using polyester POY as raw material, the processing method flow chart is as follows figure 1 As shown, the production process is as follows: original wire frame → first roller 1 → deformation heating box 2 → cooling plate 3 → false twist deformation 4 → second roller 5 → shaping heating box 6 → third roller 7 → oiling → coiling Winding → grading packaging. In the present invention, the temperature of the deformation heating box is increased to 210-240°C, which is near the limit condition of thermal deformation of polyester yarn, and the setting heating box is closed, and the setting is cooled at ambient temperature, in order to improve the crimping and shrinkage of the yarn Rate, and then improve the elasticity of the yarn, set the processing speed of the production line to 400~550m / min, during the processing, reduce the network and increase the fineness of the single filament. In addition, in order to increase the cr...

Embodiment 4

[0025] [Example 4 ~ 5]

[0026] A processing method of high-elastic polyester yarn, the processing technology, raw materials, processing machine, crimp shrinkage testing instrument and method, and unwinding performance testing instrument are all the same as those in Examples 1-3.

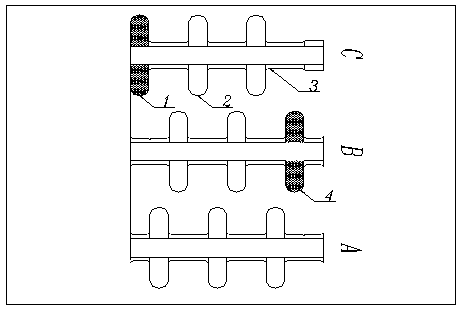

[0027] In Examples 4-5, the temperature of the deformation heating box is set to 225°C, the shaping heating box is turned off, and the combination modes of the false twisters are respectively set to 1-5-1 and 1-6-1. Schematic diagram of the combination mode of the false twisters Such as figure 2 As shown, it includes the driving shaft A, the driven shaft B, the driven shaft C, the output disc 1, the working disc 2, the spacer 3 and the leading disc 4. On the shaft A and the driven shaft B, spacers 3 are set in series between the working discs to keep a constant distance.

Embodiment 6~7

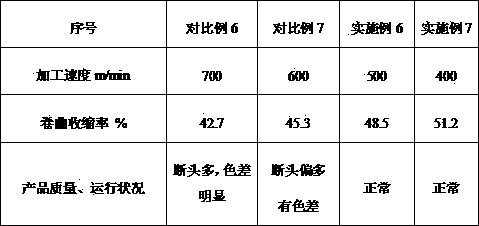

[0035] A processing method of high-elastic polyester yarn, the processing technology, raw materials, processing machine, crimp shrinkage testing instrument and method, and unwinding performance testing instrument are all the same as those in Examples 1-3.

[0036] In Examples 6-7, the temperature of the deformation heating box is set to 225°C, the setting heating box is closed, the false twister combinations are set to 1-5-1 and 1-6-1 respectively, and the speed of the production line is set to 500m / min and 400m / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com