High-plasticity steel hot-rolled coil for welded gas cylinder and production technology of high-plasticity steel hot-rolled coil

A technology of steel for gas cylinders and hot-rolled coils. It is applied in the field of steel for welding gas cylinders. It can solve the problems of not meeting the requirements of suppliers and the difficulty of obtaining uniform structures, so as to improve the strength, increase the bottle forming rate, and improve the performance. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, the hot-rolled coil of steel for high-plasticity welded gas cylinders, the mass percentage of chemical composition is: C: 0.12%, Mn: 0.75%, P: 0.0143%, S: 0.0015%, Als: 0.026% , The balance is Fe and impurity elements.

[0023] The steel undergoes converter smelting, ladle argon blowing, ladle refining furnace refining, and continuous casting. After heating, it enters two-stand rough rolling, and then passes through seven continuous rolling mills for finishing, and finally is cooled and coiled after rolling.

[0024] Among them, the rolling process parameters are: heating temperature 1200°C, bloom opening temperature 1150°C, finishing rolling opening temperature 1000°C, finishing rolling temperature 890°C,

[0025] The cooling process adopts intermittent water curtain laminar cooling, the water cooling rate is 18℃ / S, and the final cooling temperature is 630℃.

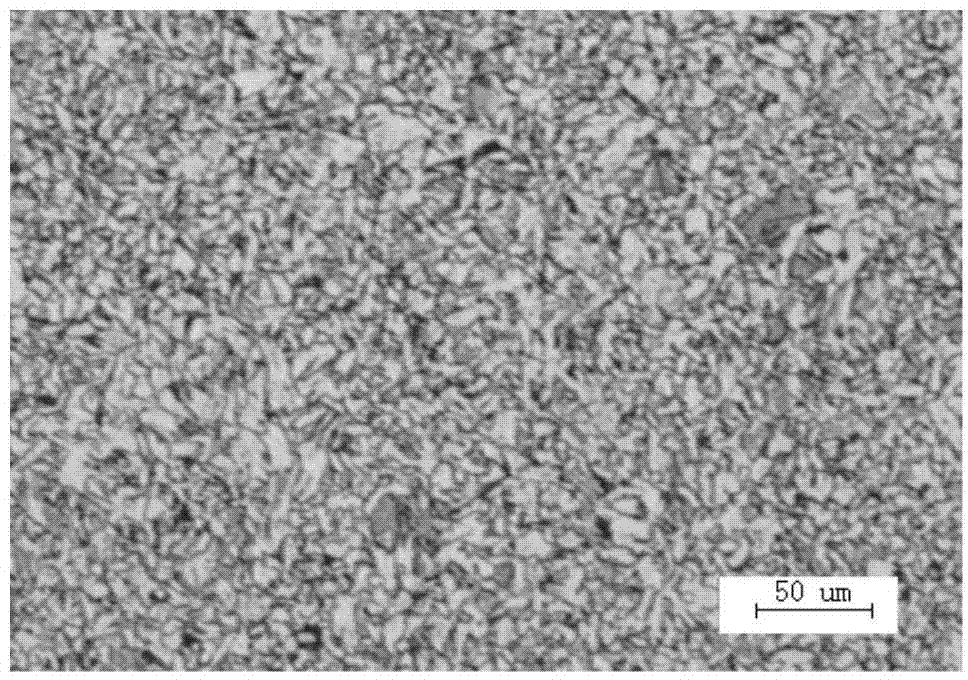

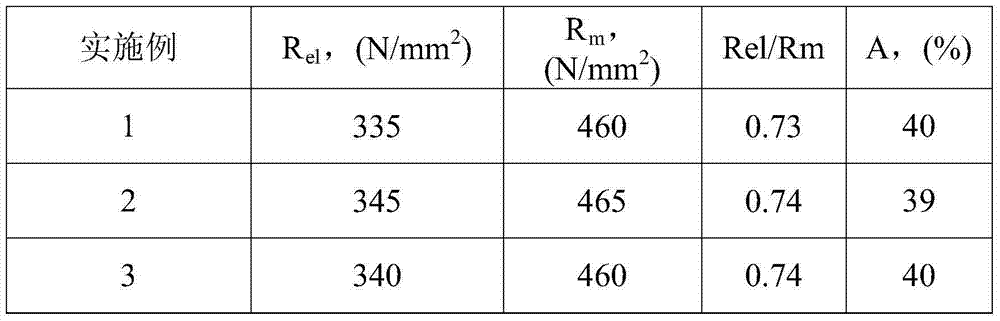

[0026] The mechanical properties of welded gas cylinder steel are shown in Table 1, and the metallograph...

Embodiment 2

[0027] Embodiment 2, the hot-rolled coil of steel for high-plasticity welded gas cylinders, the mass percentage of chemical composition is: C: 0.13%, Mn: 0.73%, P: 0.0112%, S: 0.0010%, Als: 0.029% , The balance is Fe and impurity elements.

[0028] The steel undergoes converter smelting, ladle argon blowing, ladle refining furnace refining, and continuous casting. After heating, it enters two-stand rough rolling, and then passes through seven continuous rolling mills for finishing, and finally is cooled and coiled after rolling.

[0029] Among them, the rolling process parameters are: heating temperature 1200°C, bloom opening temperature 1165°C, finishing rolling opening temperature 950°C, finishing rolling temperature 895°C,

[0030] The cooling process adopts intermittent water curtain laminar cooling, the water cooling rate is 19℃ / S, and the final cooling temperature is 625℃.

[0031] The mechanical properties of welded gas cylinder steel are shown in Table 1.

Embodiment 3

[0032] Example 3, the hot-rolled coil of steel for high-plasticity welded gas cylinders, the mass percentage of chemical composition is: C: 0.14%, Mn: 0.75%, P: 0.0122%, S: 0.0012%, Als: 0.027% , The balance is Fe and impurity elements.

[0033] The steel undergoes converter smelting, ladle argon blowing, ladle refining furnace refining, and continuous casting. After heating, it enters two-stand rough rolling, and then passes through seven continuous rolling mills for finishing, and finally is cooled and coiled after rolling.

[0034] Among them, the rolling process parameters are: heating temperature 1190°C, bloom opening temperature 1170°C, finishing rolling opening temperature 1000°C, finishing rolling temperature 850°C,

[0035] The cooling process adopts intermittent water curtain laminar cooling, the water cooling rate is 25℃ / S, and the final cooling temperature is 610℃.

[0036] The mechanical properties of welded gas cylinder steel are shown in Table 1.

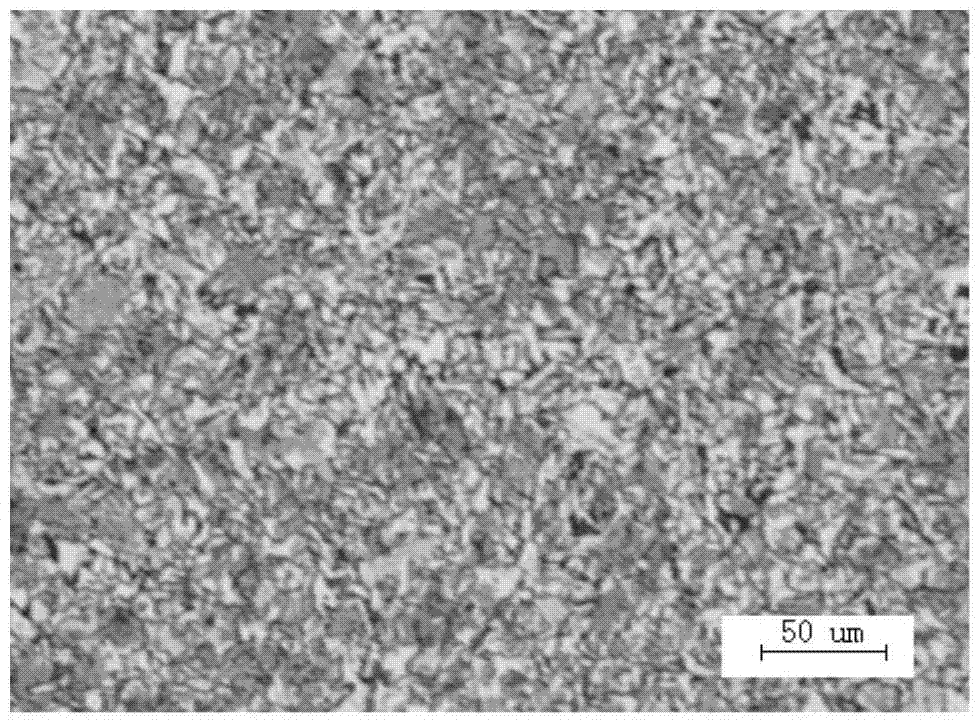

[0037] The metallograp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com