Compound flux of high-MgO sinter ore, and preparation method and application of the compound flux

A technology of composite flux and sinter, applied in the field of iron ore powder sintering, can solve the problems of poor strength of high MgO sinter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of composite flux for strengthening the production of high-MgO type sinter, the water-soluble additive is B2O3, which is dissolved in water to make an aqueous solution; the source of MgO is magnesium oxide (MgO), and the mass ratio of MgO and B2O3 is 100:2, so that B2O3 adheres to the surface of the MgO source material, put it in an oven for drying at 95°C, and obtain a composite flux that strengthens the production of high-MgO sinter.

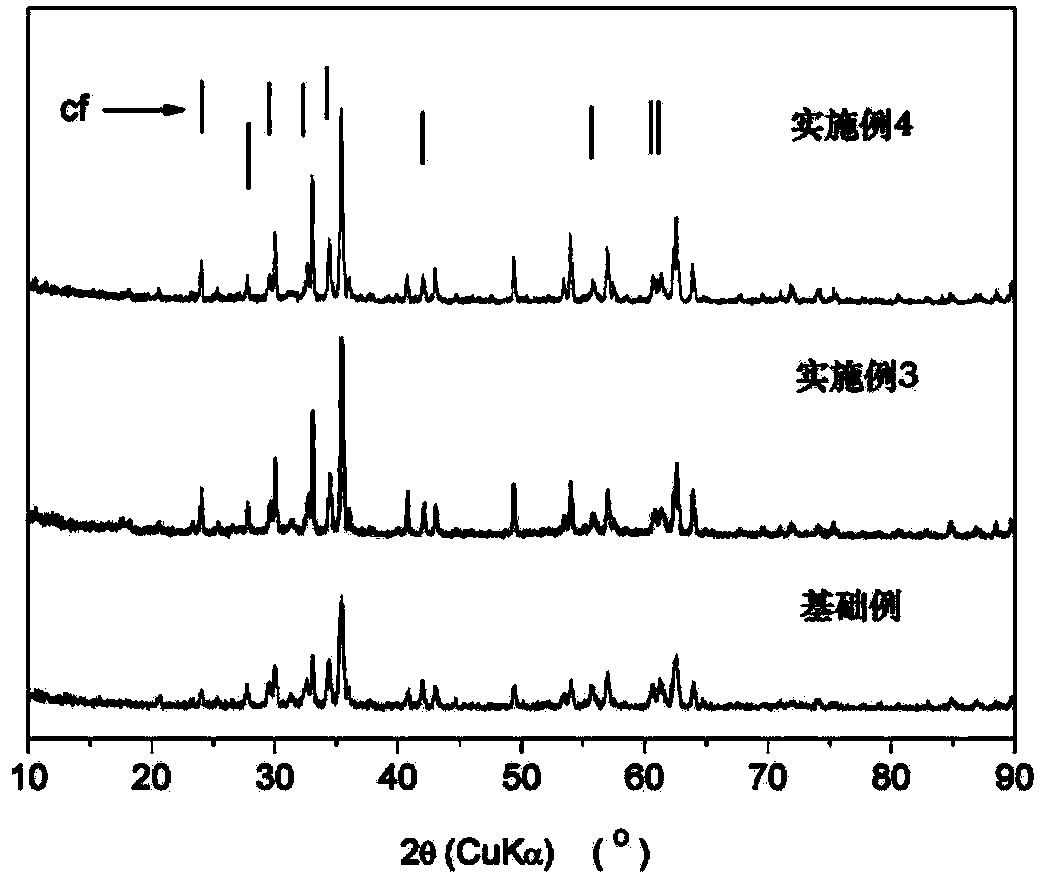

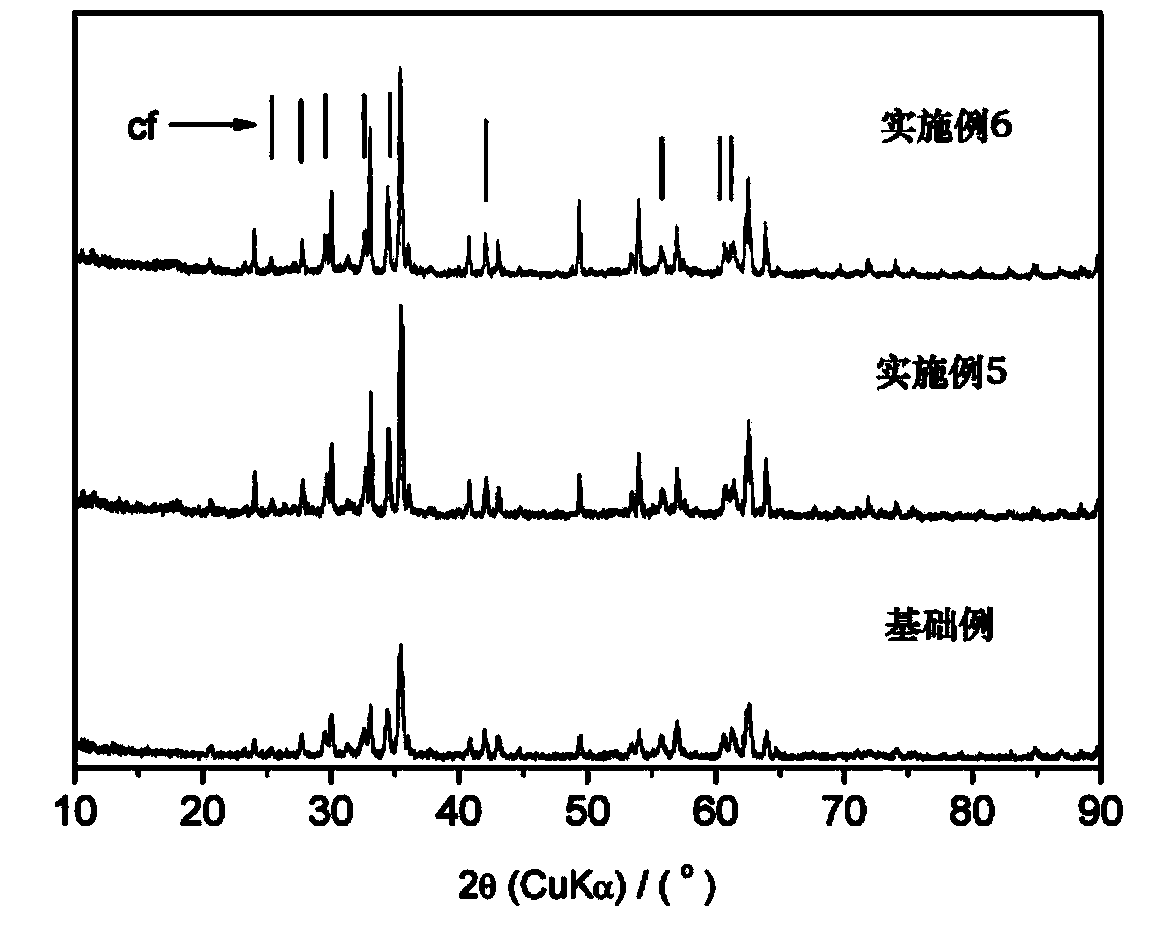

[0033] Mix the composite flux with iron ore powder and quicklime, and the mixing ratio is calculated based on the basicity of 2.0 and 4% MgO in the sinter composition. Sinter in an air atmosphere, mix the mixture, take 2g and put it into a φ15mm die, press it into a round cake at a pressure of 5MPa, put it into the furnace at 500°C, and raise the temperature to 1250°C at a speed of 20°C / min Sintering is carried out, and after reaching the temperature, the sample is taken out and cooled in air. Test the X-ray diff...

Embodiment 2

[0036] The preparation method of composite flux for strengthening the production of high-MgO type sinter, the water-soluble additive is B2O3, which is dissolved in water to make an aqueous solution; the source of MgO is magnesium oxide (MgO), and the mass ratio of MgO and B2O3 is 10:1. B2O3 adheres to the surface of the MgO source material, put it in an oven for drying at 95°C, and obtain a composite flux that strengthens the production of high-MgO sinter.

[0037] Mix the composite flux with iron ore powder and quicklime, and the mixing ratio is calculated based on the basicity of 2.0 and 4% MgO in the sinter composition. Sinter in an air atmosphere, mix the mixture, take 2g and put it into a φ15mm die, press it into a round cake at a pressure of 5MPa, put it into the furnace at 500°C, and raise the temperature to 1250°C at a speed of 20°C / min Sintering is carried out, and after reaching the temperature, the sample is taken out and cooled in air. Test the X-ray diffraction c...

Embodiment 3

[0040] The preparation method of composite flux for strengthening the production of high-MgO type sinter, the water-soluble additive is CaCl2, which is dissolved in water to make an aqueous solution; the source of MgO is magnesite (MgCO3), and the mass ratio of MgCO3 and CaCl2 is 50:2. Make CaCl2 adhere to the surface of MgCO3 material, put it in an oven for drying at 90°C, and obtain a composite flux that strengthens the production of high-MgO sintered ore.

[0041] Mix the composite flux with iron ore powder and quicklime, and the mixing ratio is calculated based on the basicity of 2.0 and 3% MgO in the sinter composition. Sinter in an air atmosphere, mix the mixture, take 2g and put it into a φ15mm die, press it into a round cake at a pressure of 5MPa, put it into the furnace at 500°C, and raise the temperature to 1250°C at a speed of 20°C / min Sintering is carried out, and after reaching the temperature, the sample is taken out and cooled in air. Test the X-ray diffraction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com