Glass pane manufacturing method and glass pane manufacturing device

A manufacturing method and glass plate technology, applied in glass manufacturing equipment, glass forming, glass forming, etc., can solve the problems of glass plate thickness deviation, temperature distribution, forming furnace temperature distribution, etc., and achieve the effect of suppressing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

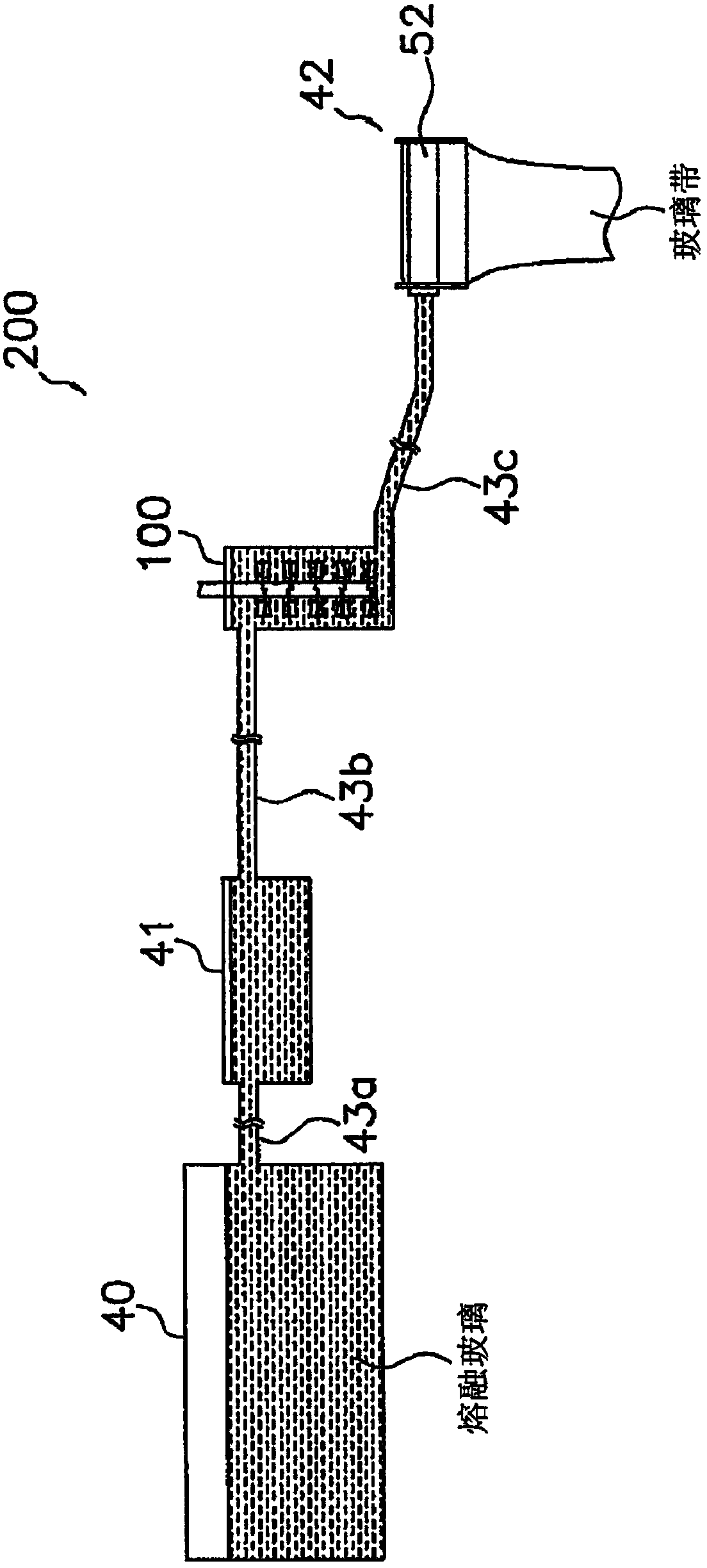

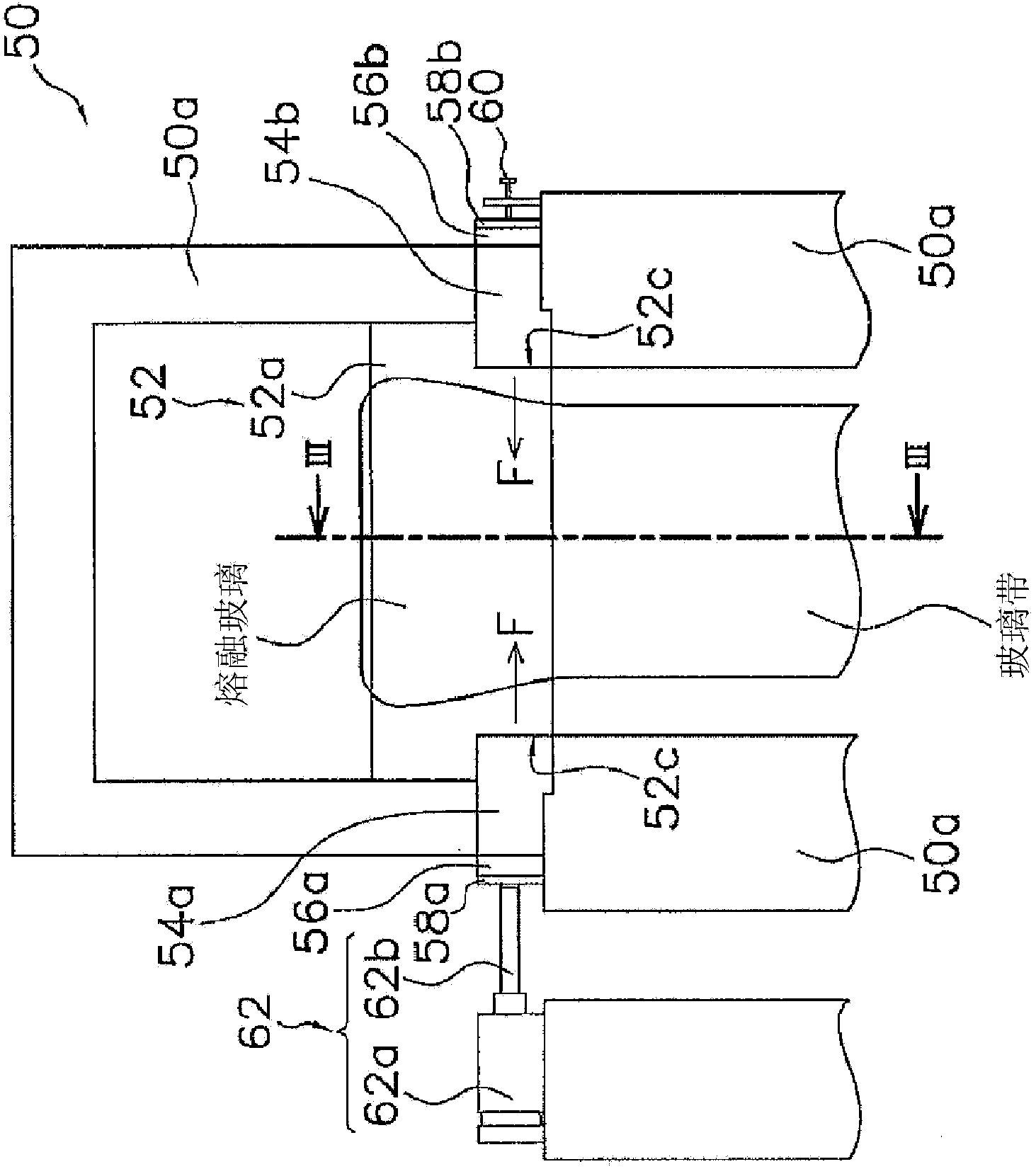

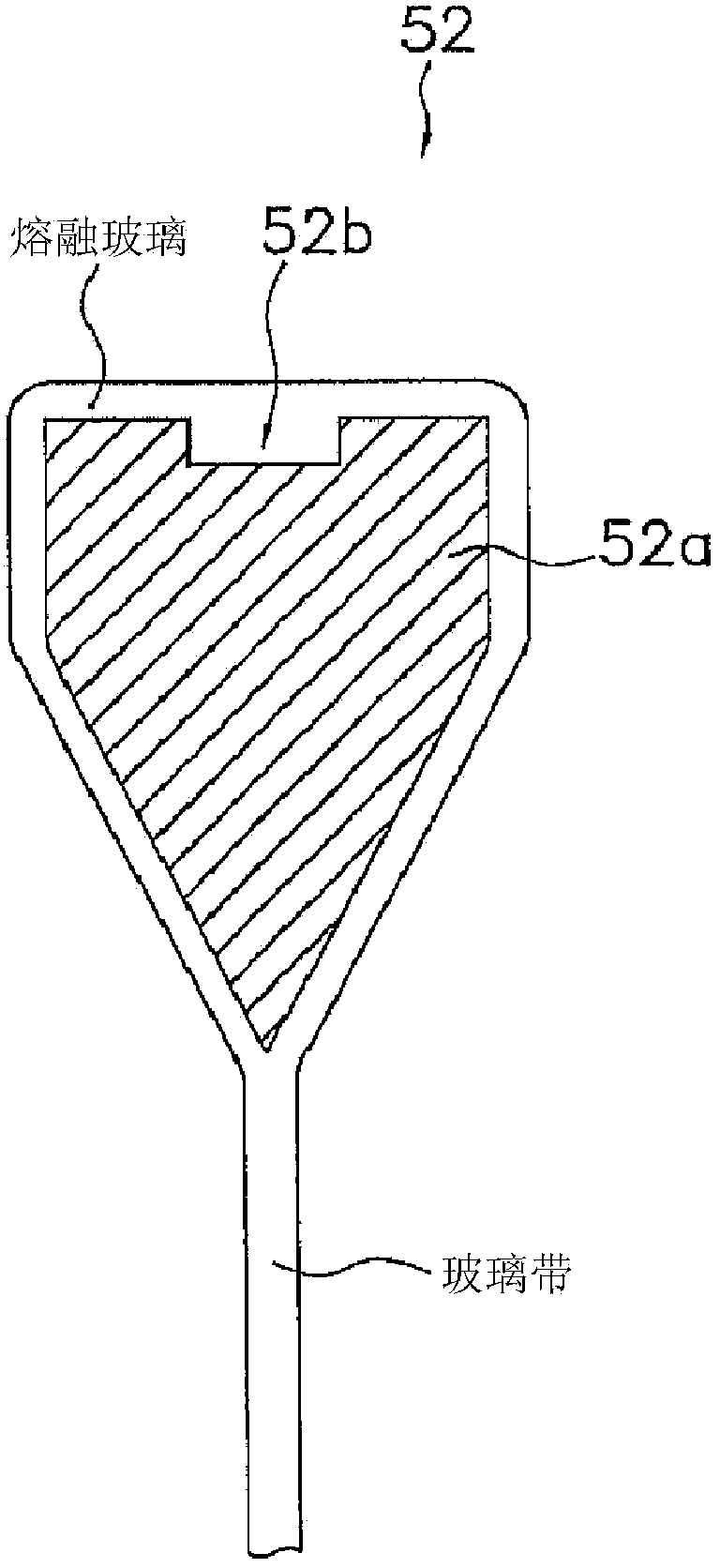

[0037] (1) The overall configuration of the glass plate manufacturing equipment

[0038] Embodiments of the manufacturing method of the glass plate of this invention, and the manufacturing apparatus of a glass plate are demonstrated, referring drawings. figure 1 It is a schematic diagram which shows an example of the structure of the glass plate manufacturing apparatus 200 of this embodiment. The glass plate manufacturing apparatus 200 is equipped with the melting tank 40, the clarification tank 41, the stirring apparatus 100, the shaping|molding apparatus 42, and conduit|pipe 43a, 43b, 43c. The conduit 43a connects the melting tank 40 and the clarification tank 41 . The conduit 43b connects the clarification tank 41 and the stirring device 100 . The conduit 43c connects the stirring device 100 to the forming device 42 .

[0039] The molten glass produced|generated in the melting tank 40 flows into the clarification tank 41 through the conduit|pipe 43a. The molten glass clar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap