Thorough cut sludge elutriation separator stirring device

A technology of stirring device and communicating sludge, which is applied in the field of mixing device of mud washing and separating machine, can solve the problems of overload of motor, easy wear of paddles, high sand and gravel content, etc., so as to prolong the service life and seal The effect of good effect and simple sealing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

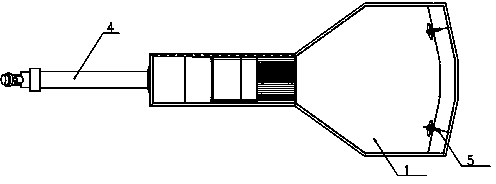

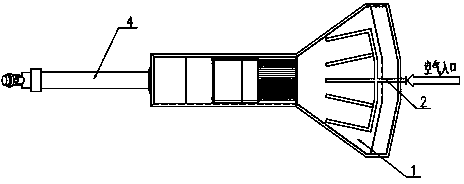

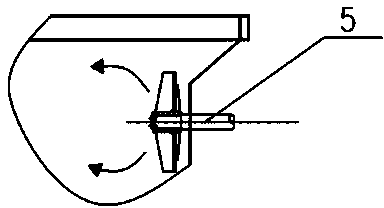

[0018] like figure 2 As shown, the structure diagram of the ditch sludge elutriation separator of the present invention is to change the existing mechanical agitation device into an air agitation device, which consists of a sludge tank 1, a microporous aeration device 2, a slag removal machine 3. The grit settling conveyor 4 is composed; the inlet of the aeration device pipeline is arranged at the front end of the sludge tank 1, and the aeration pipeline in the sludge tank is laid flat on the bottom of the sludge tank, and the installation direction is the same as the flow direction of the cleaning water consistent, such as Figure 4 As shown, prevent the pipeline from blocking the sludge.

[0019] The present invention adopts the aeration air flotation method, and adopts a blower and a microporous aeration device 2 . The blower (not shown in the figure) sends the air to the microporous aeration device, and the air outlet is located under the microporous aeration pipe to pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com