High-recovery-rate saline wastewater membrane combination and separation process and application

A salty wastewater and high recovery rate technology, applied in the field of water treatment and resource recycling, can solve the problems of increasing water treatment costs, increasing treatment process costs, increasing pre-coagulation treatment, etc., to achieve good system recovery rate and operation Stability, ensuring operation stability and separation effect, reducing equipment investment and operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

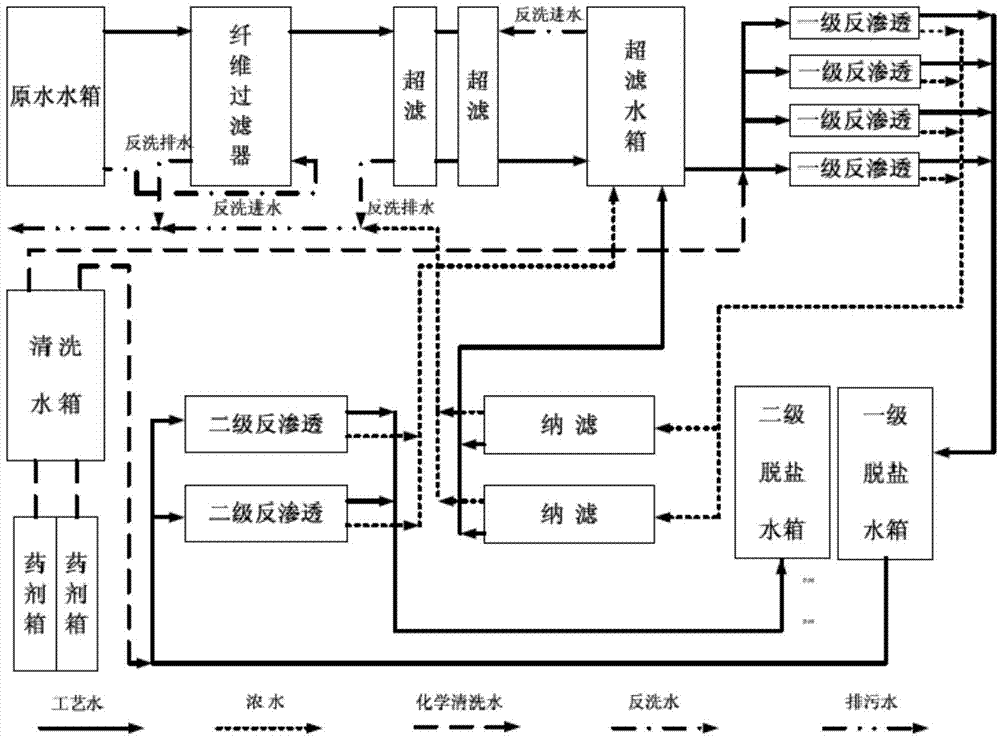

[0029] Embodiment 1: Desalination treatment of underground brackish water

[0030] Using NaCl to simulate the total dissolved solids is 10000mg / L, the pH is 9.0, and the temperature is the underground brackish water of 16.8°C, and the process equipment and flow process of the present invention (such as figure 1 shown) for processing. The ultrafiltration membrane in the equipment is a hollow fiber internal pressure ultrafiltration membrane. The material of the ultrafiltration membrane is modified PVDF, the inner diameter of the fiber is 1.0mm, and the surface pore diameter of the membrane is 0.01μm; It is aromatic polyamide, and the surface pore diameter of the membrane is 0.5nm; the nanofiltration membrane is a coiled membrane, and the material of the nanofiltration membrane is aromatic polyamide, and the surface pore diameter of the membrane is 1.0nm.

[0031] When treating wastewater, the prepared raw water is injected into the raw water tank first, and the fiber filter and...

Embodiment 2

[0035]Example 2: Recycling and treatment of power plant circulating cooling sewage

[0036] The water quality of circulating cooling wastewater from a power plant is: pH=6.0, turbidity 23.7NTU, conductivity 2255μs / cm, treated with the process equipment and method of the present invention. The difference from the above-mentioned Example 1 is that in order to ensure better effluent water quality, a second-stage reverse osmosis is added after the water produced by the first-stage reverse osmosis. The feed water of the secondary reverse osmosis is the product water of the primary reverse osmosis, and the concentrated water of the secondary reverse osmosis is returned to the ultrafiltration water tank. During the operation of the equipment, set the ultrafiltration operation for 20 minutes and backwash for 20 seconds through the relay; adjust the inlet water pressure of the first-stage reverse osmosis to about 0.5Mpa and the inlet water pressure of nanofiltration to about 0.3Mpa by ...

Embodiment 3

[0038] Embodiment 3: the recycling treatment of PVC production sewage

[0039] The drainage water quality of a PVC production enterprise is as follows: pH=8.4, turbidity 18.7NTU, conductivity 1310μs / cm, treated with the process equipment and method of the present invention. The difference from the above-mentioned Example 1 is that during the operation of the equipment, the ultrafiltration operation is set by the relay for 10 minutes, and the backwashing is 10s; by adjusting the nanofiltration inlet water and the concentrated water valve, the primary reverse osmosis inlet water pressure is adjusted to about 0.6Mpa, and the nanofiltration The water inlet pressure is about 0.4Mpa. The operation results show that the desalination rate of the system reaches 99.0%, and the total recovery rate reaches 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com