Composite flocculating agent and preparation method thereof

A technology of composite flocculant and sulfuric acid method, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of increasing the operating cost of titanium dioxide production enterprises, loss, and high cost of titanium dioxide waste acid, so as to increase added value and decontamination Strong ability, good for environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

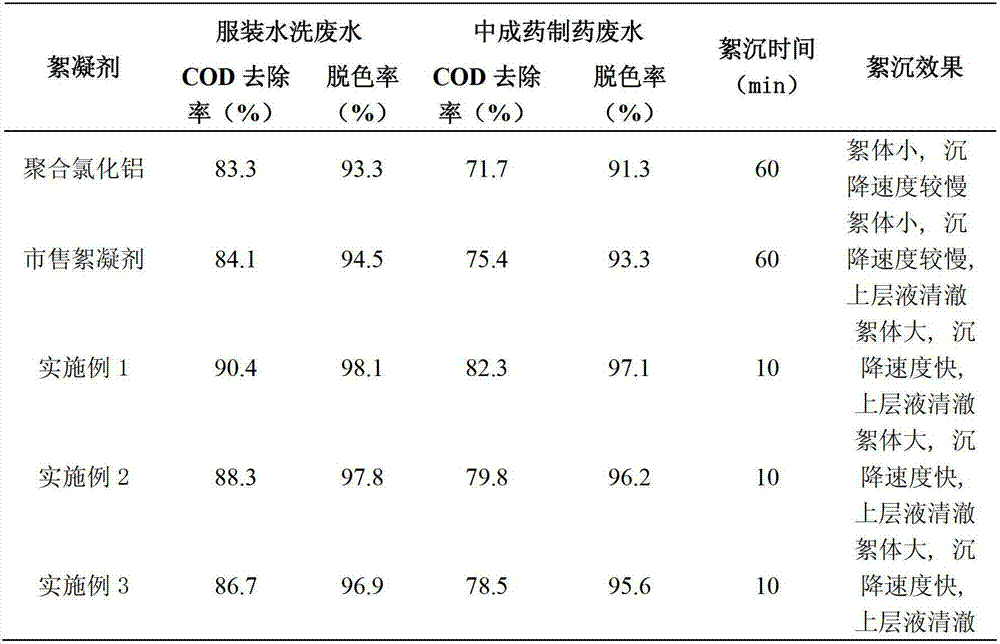

Examples

Embodiment 1

[0025] (1) Cut 2.0g of waste nylon socks into small pieces and add to 120mL of titanium dioxide waste acid, stir and boil for 15 minutes to dissolve;

[0026] (2) Add 200mL of water, 40g of ferrous sulfate heptahydrate, 15g of potassium chlorate, 0.6g of fly ash and 5g of pre-alkalized starch to the mixture in step (1);

[0027] (3) Stir and react the mixed solution in step (2) in a constant temperature magnetic stirrer. During the reaction, the pH of the reaction solution is controlled at 1-1.5, the reaction temperature is 60°C, and the reaction time is 2.0h;

[0028] (4) The solid-liquid separation of the reaction solution in step (3) yielded about 260mL of liquid composite flocculant, and the product was stored for 3 months without gelling.

Embodiment 2

[0030] (1) Cut 1.0g of waste nylon socks into small pieces and add to 120mL of titanium dioxide waste acid, stir and boil for 12 minutes to dissolve;

[0031] (2) Add 200mL of water, 60g of ferrous sulfate heptahydrate, 15g of potassium chlorate, 0.6g of fly ash and 5g of pre-alkalized starch to the mixture in step (1);

[0032] (3) Stir and react the mixed solution in step (2) in a constant temperature magnetic stirrer. During the reaction, the pH of the reaction solution is controlled at 1-1.5, the reaction temperature is 60°C, and the reaction time is 2.0h;

[0033] (4) The solid-liquid separation of the reaction solution in step (3) yielded about 270mL of liquid composite flocculant, and the product was stored for 3 months without gelling.

Embodiment 3

[0035] (1) Cut 1.5g of waste nylon socks into small pieces and add to 120mL of titanium dioxide waste acid, stir and boil for 15 minutes to dissolve;

[0036] (2) Add 200mL of water, 80g of ferrous sulfate heptahydrate, 15g of potassium chlorate, 0.6g of fly ash and 5g of pre-alkalized starch to the mixture in step (1);

[0037] (3) Stir and react the mixed solution in step (2) in a constant temperature magnetic stirrer. During the reaction, the pH of the reaction solution is controlled at 1-1.5, the reaction temperature is 60°C, and the reaction time is 1.0h;

[0038] (4) The solid-liquid separation of the reaction solution in step (3) yielded about 260mL of liquid composite flocculant, and the product was stored for 3 months without gelling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com