Vertical-flow self-aeration annular artificial wetland system

A constructed wetland system and automatic oxygenation technology, applied in sustainable biological treatment, energy wastewater treatment, water/sludge/sewage treatment, etc., can solve the problems of easy clogging of openings, no environmental conditions, and increased concentration. Achieve the effect of controlling mosquito breeding, reducing infrastructure investment and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

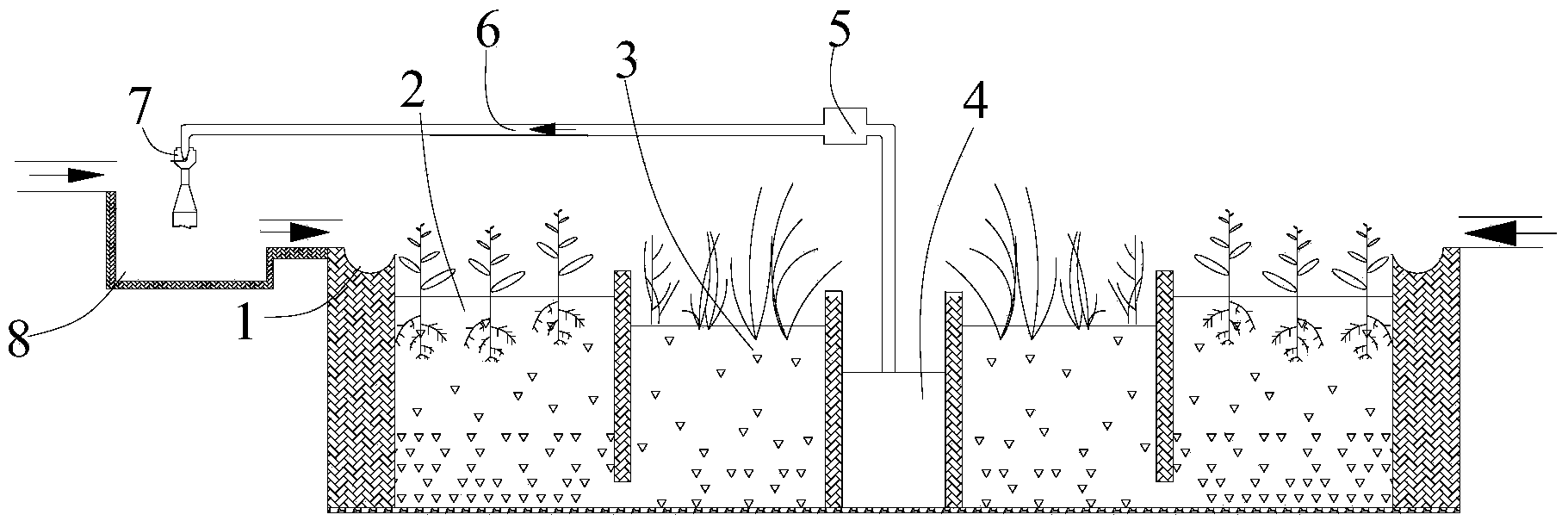

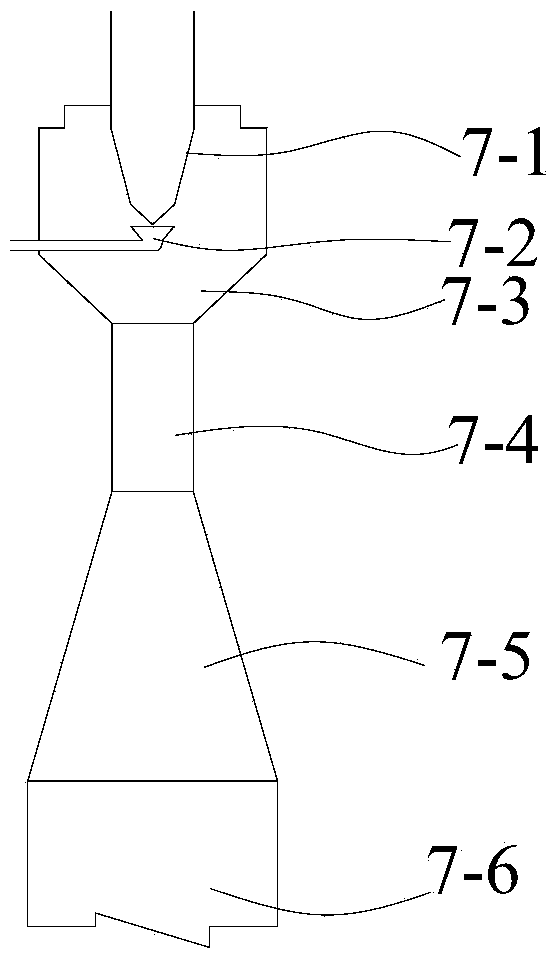

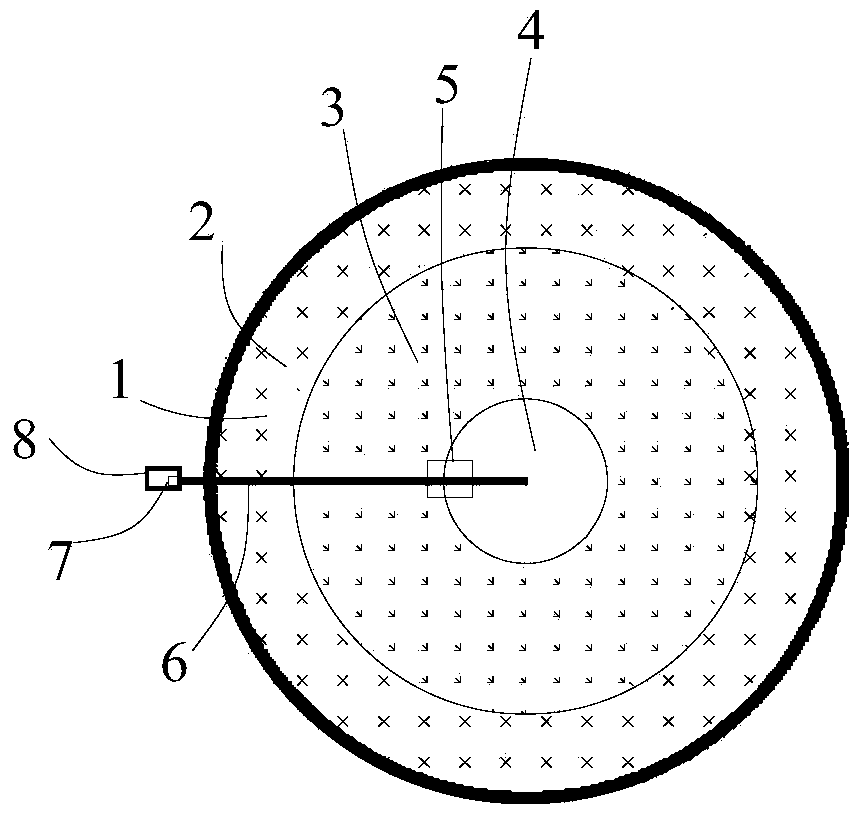

[0032] Such as figure 1 As shown, the vertical flow automatic oxygenation constructed wetland system includes a diversion groove 1, a downward flow annular pool 2, an upward flow annular pool 3, a collecting pool 4, a return pump 5, a loop pipeline 6, an automatic oxygenation return device 7 and a shallow Adjusting pool 8. The diversion groove 1 is arranged on the outer wall of the downstream annular pool, and the upstream annular pool is located inside the downstream annular pool. Both the downflow annular pool and the upflow annular pool adopt circular circulation pools, and a partition wall is arranged between them and communicated through a gap at the bottom of the partition wall.

[0033] Both the downward flow annular pool and the upward flow annular pool are equipped with fillers. The downward flow annular pool is filled with gravel layer, ceramsite layer and cinder layer in sequence from bottom to top, and the top layer is set with a semi-clay layer as a plant substrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com