Preparation method of mesoporous silica spherical nano particles with dendritic pore structure

A technology of mesoporous silica and pore structure, applied in the directions of silica, silica, nanotechnology, etc., can solve the problems of complex synthesis method, high synthesis cost, lack of precise control of particle size, etc., and achieves simple preparation method, low cost synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

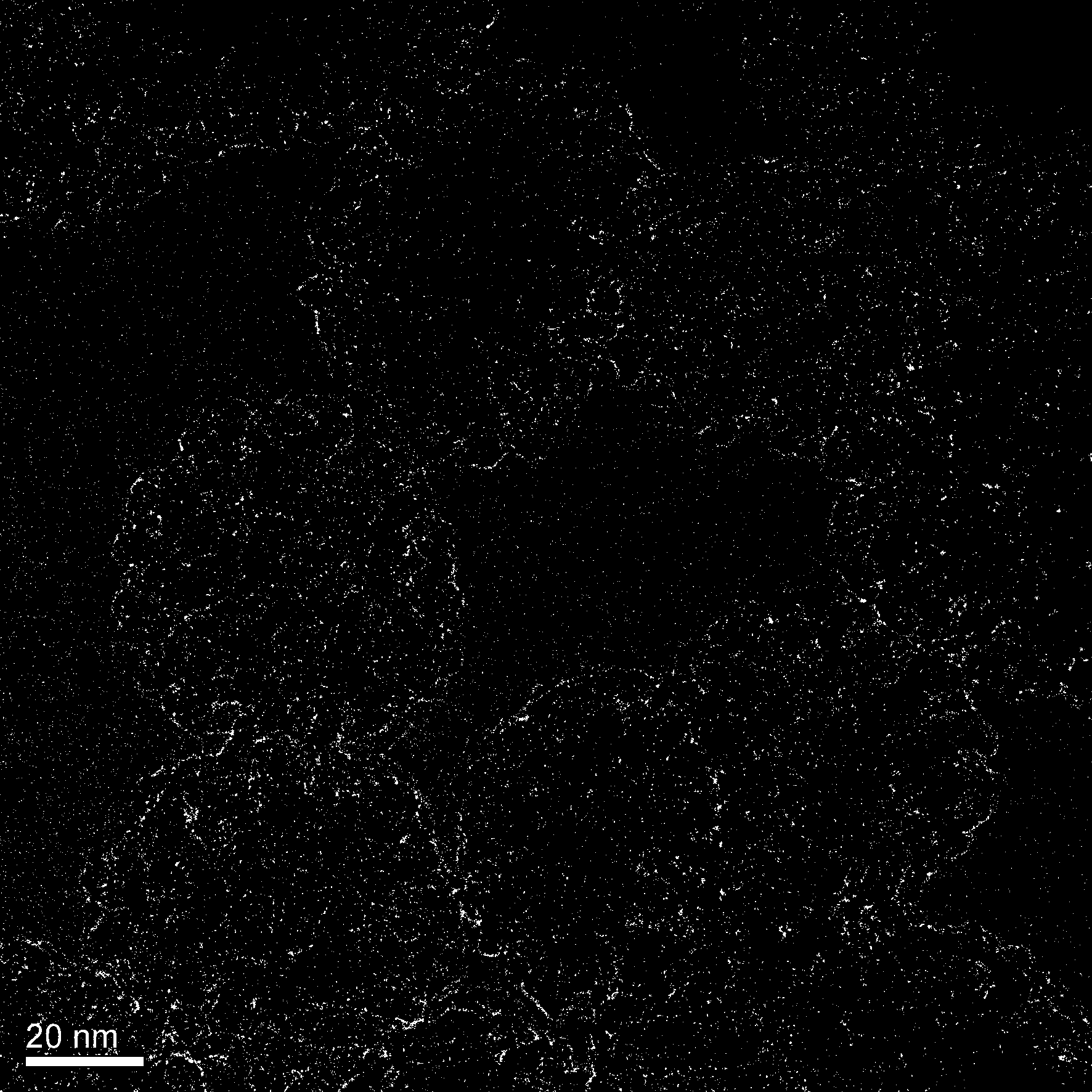

[0025] First, 2.74g of cetyltrimethylammonium p-toluenesulfonate (CTATos) and 8.33g of F127 were added to 144ml of deionized water, 14.92g of triethanolamine (TEAH 3 ) in a beaker, stirred at 80°C for 1 hour until the solution became clear, then quickly added 20.83g of tetraethoxysilicate (TEOS) into the beaker, and continued to stir at 80°C for 2 hours to obtain a stable gel state suspension, the molar composition of the mixture is SiO 2 :CTATos:TEAH 3 :F127:H 2 O = 1:0.06:1:0.0095:80; the resulting mixture was centrifuged, washed, and dried to obtain mesoporous SiO with a dendritic pore structure 2 Nanoparticles, yield 65%, average particle size 50 nm. attached figure 1 and 2 It shows that the mesoporous SiO2 nanoparticles synthesized by this method have a uniform size and a specific surface area of 1300m 2 / g, the pore volume is 2.3ml / g, and the pore diameter is between 3 and 20nm; the pore has an obvious divergent pore structure from the inside to the outside, whic...

Embodiment 2

[0027] First, 2.74g of cetyltrimethylammonium p-toluenesulfonate (CTATos) was added to a solution containing 144ml of deionized water, 0.15g of triethanolamine (TEAH 3 ) in a beaker, stirred at 80°C for 1 hour until the solution became clear, then quickly added 20.83g of tetraethoxysilicate (TEOS) into the beaker, and after stirring for 30 minutes, added 8.33g of F127 into the mixed solution. Continue to stir at a constant temperature of 80°C for 1.5 hours to obtain a stable colloidal suspension. The molar composition of the mixture is SiO 2 :CTATos:TEAH 3 :F127:H 2 O=1:0.06:1:0.0095:80; the obtained mixture was centrifuged at high speed, washed, and dried to obtain mesoporous SiO2 nanoparticles with a dendritic pore structure of large particle size, with a yield of 73% and an average particle diameter of 120 nm ; specific surface area 1200m 2 / g, the pore volume is 1.8ml / g, and the pore diameter is between 3.1 and 20nm. image 3 and 4 .

Embodiment 3

[0029] Except that tetramethoxysilicate (TMOS) was used instead of tetraethoxysilicate (TEOS) in Example 1, other preparation conditions were the same as in Example 1, and the mesoporous SiO with dendritic pore structure was obtained. 2 The average particle size of nanoparticles is 30nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com