Iron bucket transmission frame

A transmission frame and iron bucket technology, applied in the field of transmission frame, can solve the problems that the conveyor only pays attention to the transmission of the conveyor, the existence of hidden dangers, and the inconvenience of the transportation process, and achieves the effect of simple structure, reduced risk rate, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The preferred embodiments of the present invention will be described in detail below.

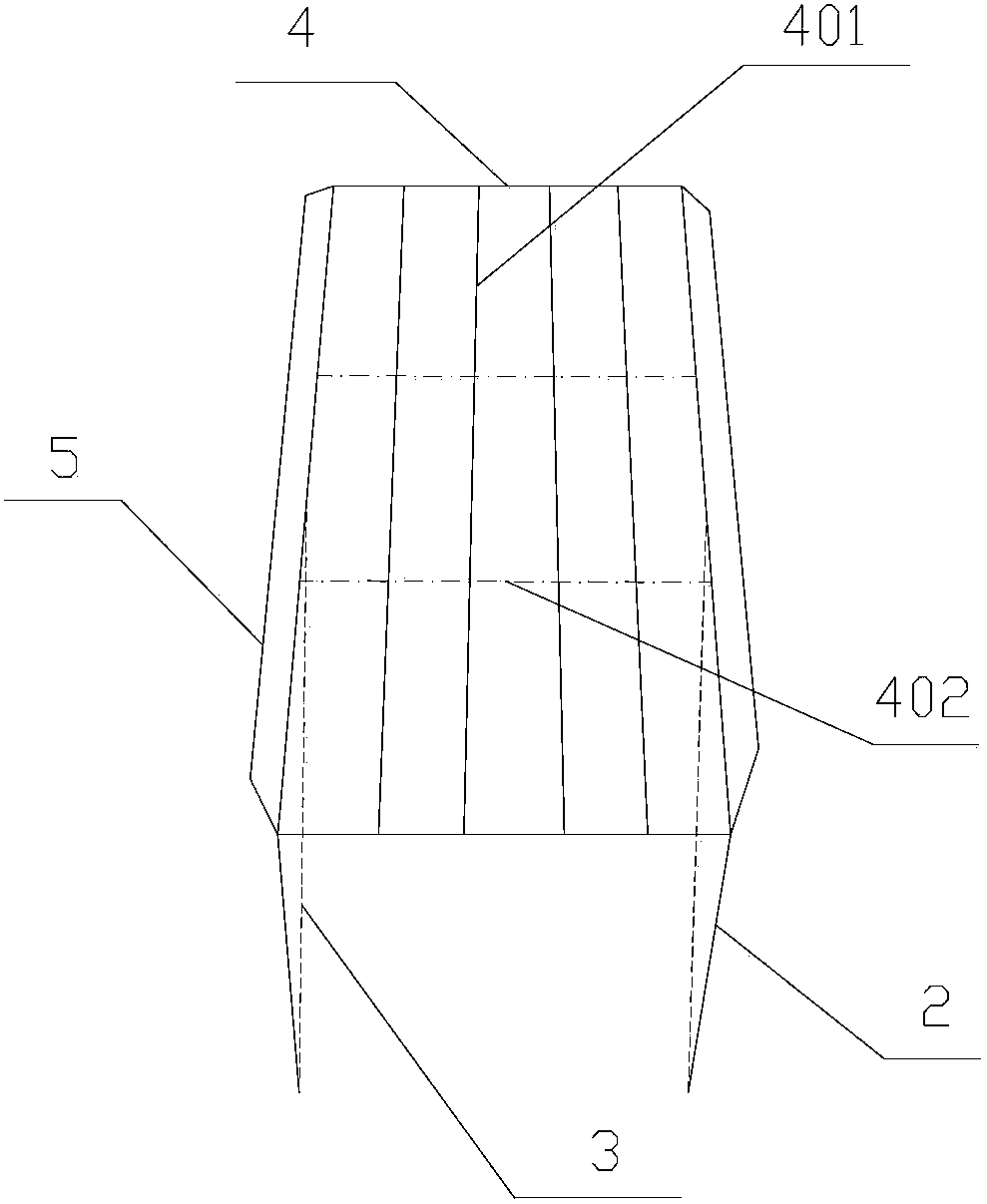

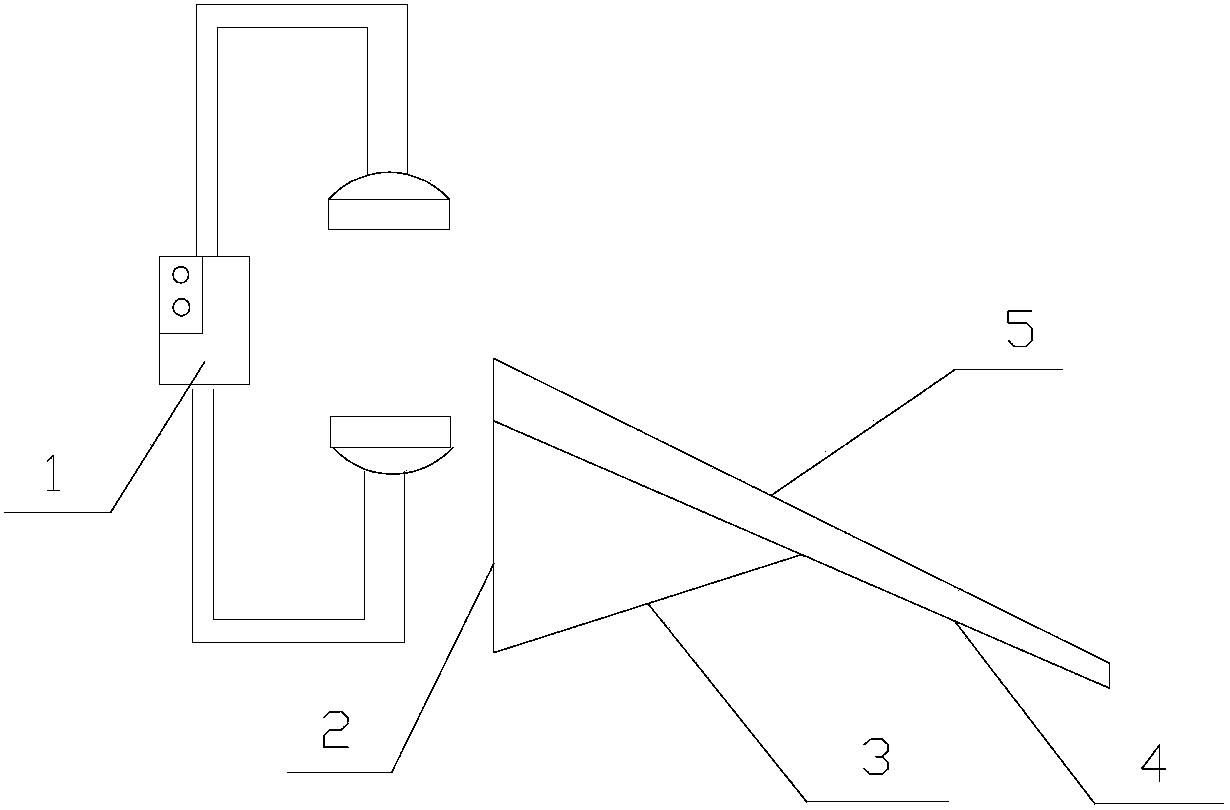

[0011] Such as figure 1 , 2 As shown, a metal barrel transmission frame is welded by a barrel making machine and a number of iron pipes, including vertical iron pipes 2, lateral support iron pipes 3, rectangular plane frames 4, square frames 5, longitudinal iron pipes 401 and horizontal iron pipe 402, which are characterized in that: six longitudinal iron pipes 401 and four horizontal iron pipes 402 are fixedly connected to form a rectangular plane frame 4, and an iron pipe is vertically connected at a right angle on one side of the short side of the frame, and the The bottom end of the vertical iron pipe 2 is fixedly connected to a side support iron pipe 3 at the midpoint of the long frame of the frame, and a square frame 5 is fixedly connected to each side of the frame surface.

[0012] The working process of the present invention: after the barrel making machine 1 finishes proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com