Buried double-layer petroleum product storage tank

A technology of double-layer storage tanks and refined oil, which is applied in the direction of containers, packaging, transportation and packaging, etc. It can solve the problems of single-layer iron storage tanks, such as hidden dangers in the quality and service life of single-layer iron storage tanks, threats to the lives of surrounding people, and environmental pollution. , to achieve the effect of eliminating the possibility of flammable, explosive or toxic substances flowing out of the outside world, protecting them from pollution, and improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

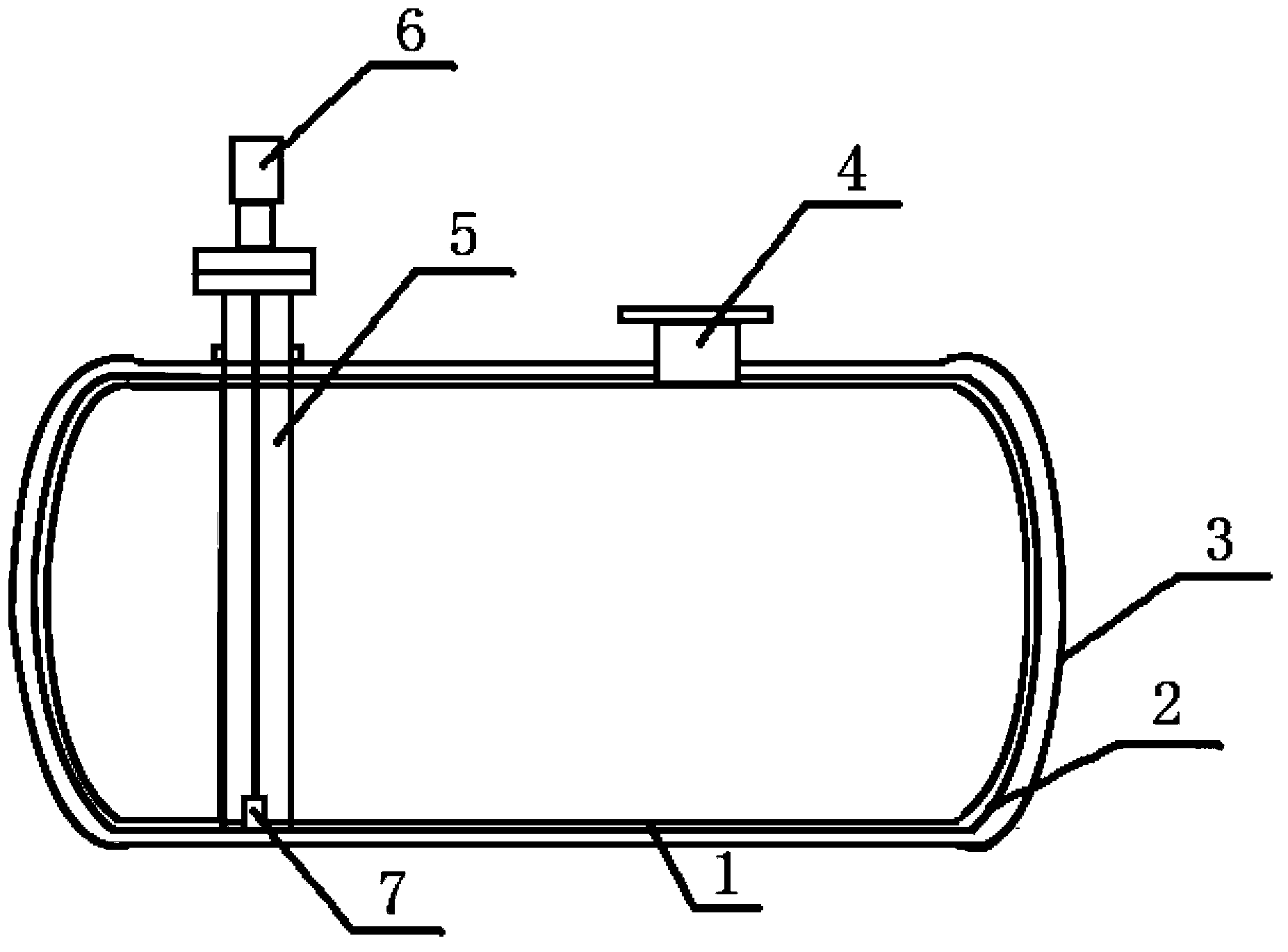

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012] Such as figure 1 As shown, the upper part of the tank body is provided with a tank hole 4, and the tank hole 4 is connected to the inner shell 3 through the outer shell 1 and the interlayer 2. The inner shell 1 is made of steel material, and the outer surface has an anti-corrosion coating layer. There is a hollow layer between the outer casings 3, the thickness of the hollow layer is 0.1-0.2mm, the outer casing 3 is made of FRP material, and the thickness of the outer casing 3 is 3-4mm, the remote monitoring leak detection system 6 detects from the leak detection tube of the storage tank The top of the leak detection pipe 5 is inserted into the bottom of the interlayer 2, and the detection sensor 7 of the remote monitoring leak detection system 6 is installed on the bottom of the leak detection pipe 5 to communicate with the interlayer 2. The present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com