Continuous powder conveying device with drying function

A conveying device and powder technology, which is applied in the field of machinery, can solve the problems of easy blockage of filters, low suspension speed, overflow, etc., achieve negative pressure pneumatic conveying and dust removal, prevent powder from adhering to the pipe, and reduce labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

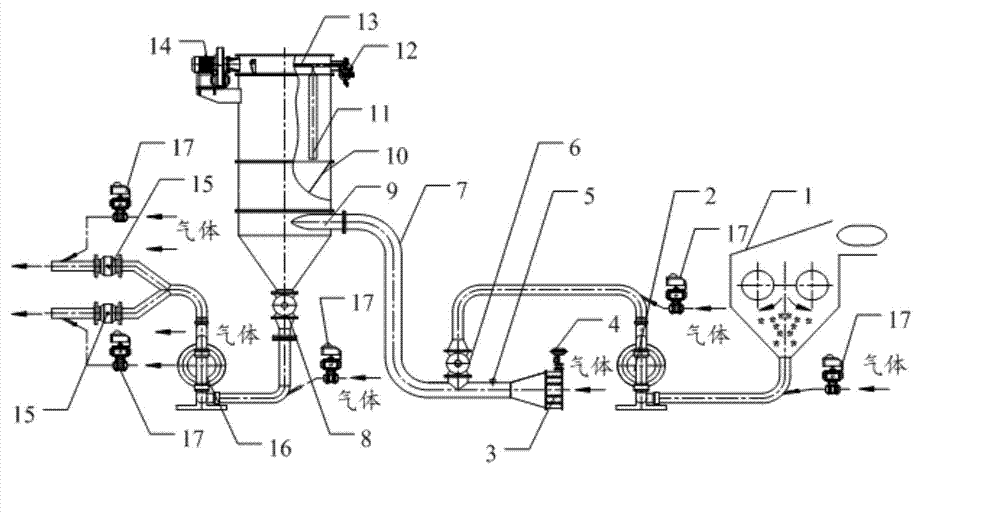

[0040] The embodiment of the present invention provides a continuous powder conveying device with a drying function, which adopts a fully automatic and fully enclosed design, and a combination of high-pressure centrifugal fan negative pressure pneumatic conveying and pneumatic diaphragm pump conveying, which can pass low power The blower fan solves the defects of the prior art.

[0041] Programmable Logic Controller (PLC) is an electronic device specially designed for digital operations in industrial environments. It uses a memory that can be programmed to store instructions for performing operations such as logic operations, sequential operations, timing, counting, and arithmetic operations, and can control various types of devices through digital or analog inputs and outputs. machinery or production process.

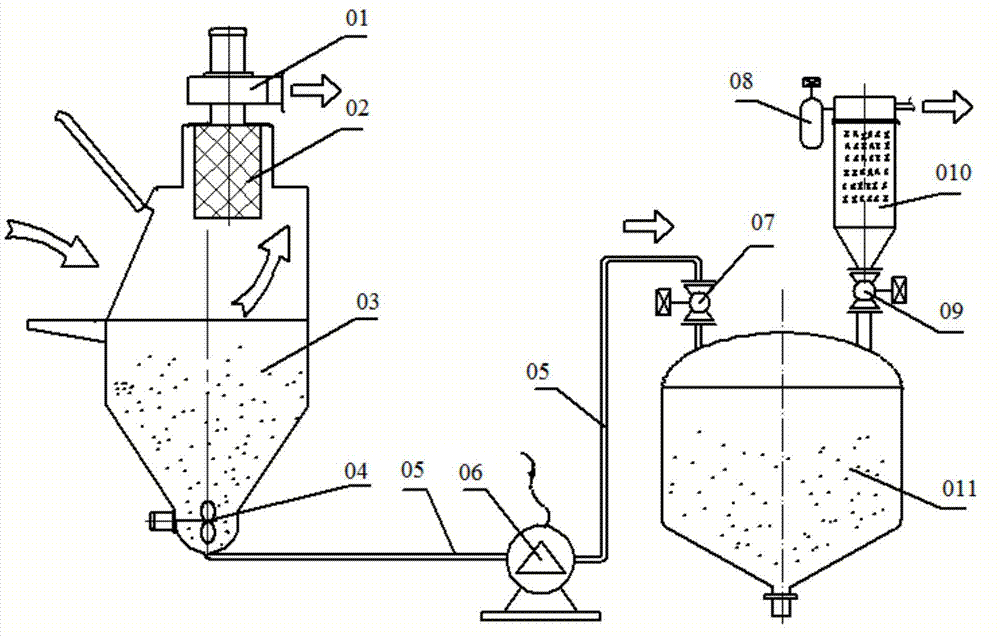

[0042] see figure 2 , The powder continuous conveying device with drying function in the embodiment of the present invention includes: an unpacking mechanism 1, a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com