Light rail soil residue vehicle

A technology for soil slag trucks and light rails, which is applied to dump trucks, transport passenger cars, railway car body parts, etc., can solve the problems of lack of versatility, complex bogie structure, procurement costs, logistics costs, manufacturing costs, and after-sales service costs. , to achieve the effect of reducing types and reducing procurement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

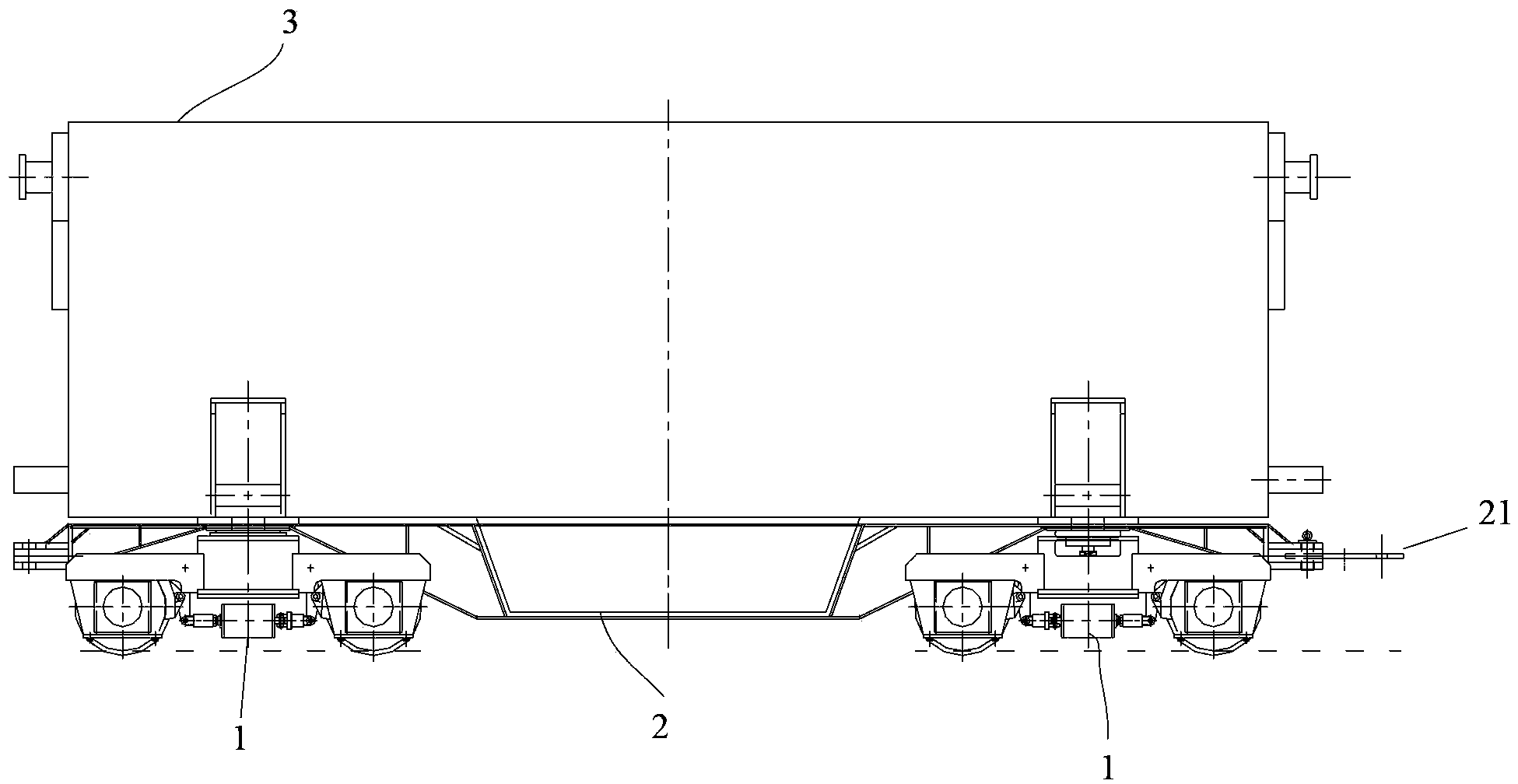

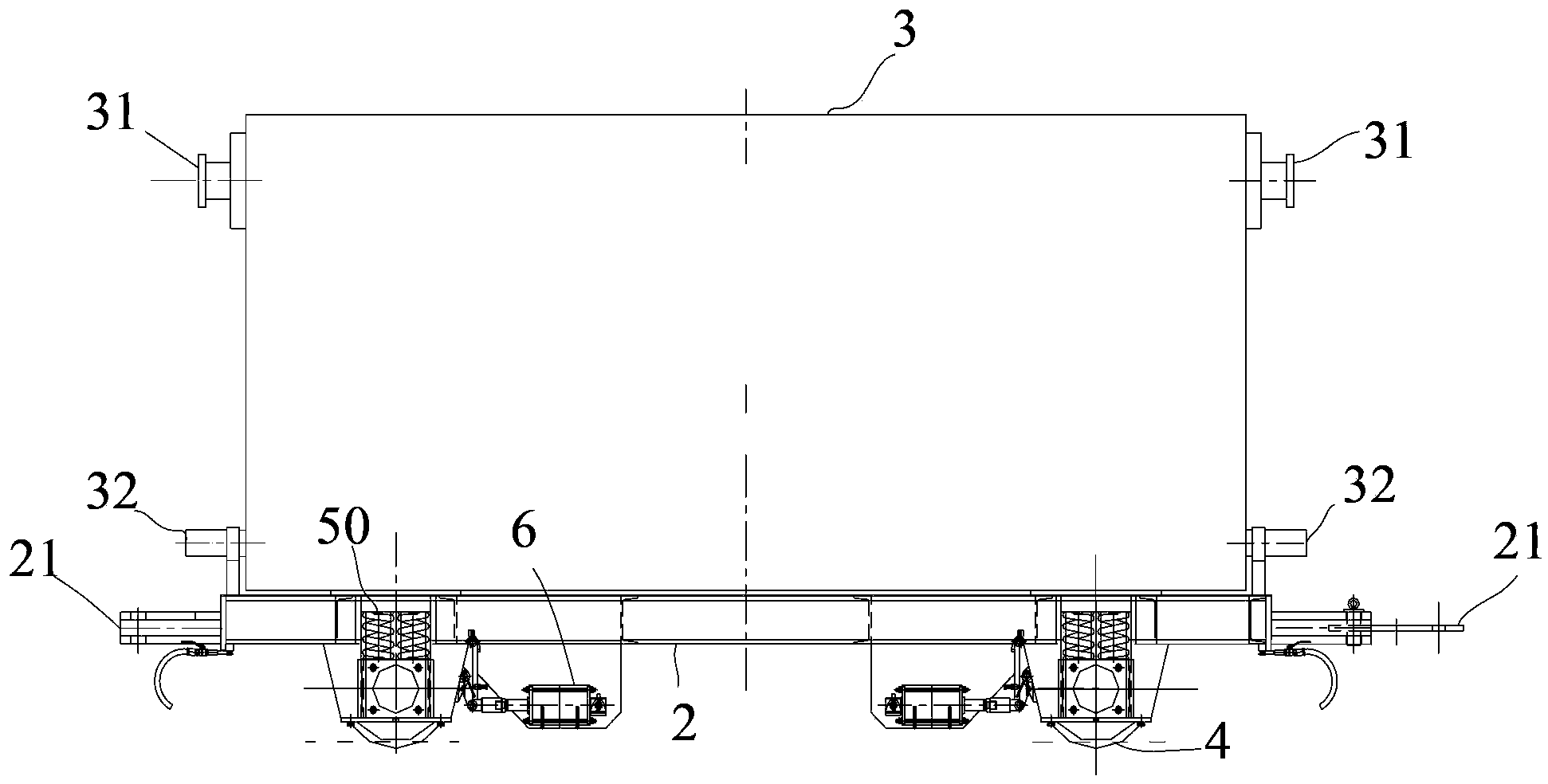

[0023] Such as Figure 3-11 As shown, the embodiment of the present invention provides a light rail earth muck truck, which includes:

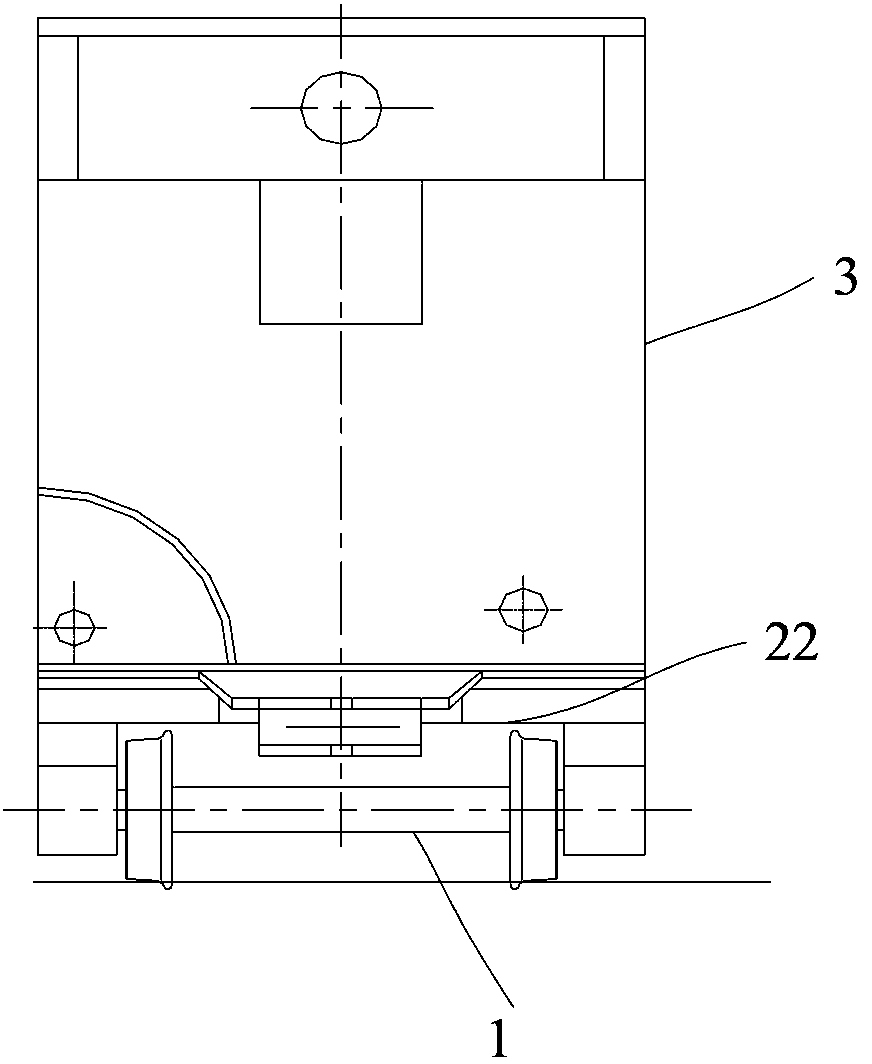

[0024] The slag hopper 3 is used to hold the slag and is symmetrical about the center line 30; both ends have a lifting shaft 31 for hoisting and a rotating shaft 32 for supporting; the connection line between the centers of the two lifting shafts 31 and the slag hopper The center line 30 coincides, and the line connecting the centers of the two rotating shafts 32 is located on the same side of the center line 30 of the slag hopper; see Figure 3-5 ;

[0025] The bottom frame 2 is used to carry the slag hopper 3. On the top surface, there are two positioning plates 23 adapted to the positions of the rotating shafts 32. The positioning plates 23 are provided with U-shaped grooves 24, and the rotating shafts 32 are respectively placed in the U-shaped grooves. 24 inside; both ends have a traction coupling 21 for connection; see Figure 6-8 ; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com