Reciprocating mechanism for mini-tiller tilling cutter machining

A technology of reciprocating mechanism and micro tillage machine, which is applied in the direction of manufacturing tools and other manufacturing equipment/tools, etc. It can solve the problems of manual grinding range and frequency instability, and achieve the effect of good processing effect, stable frequency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

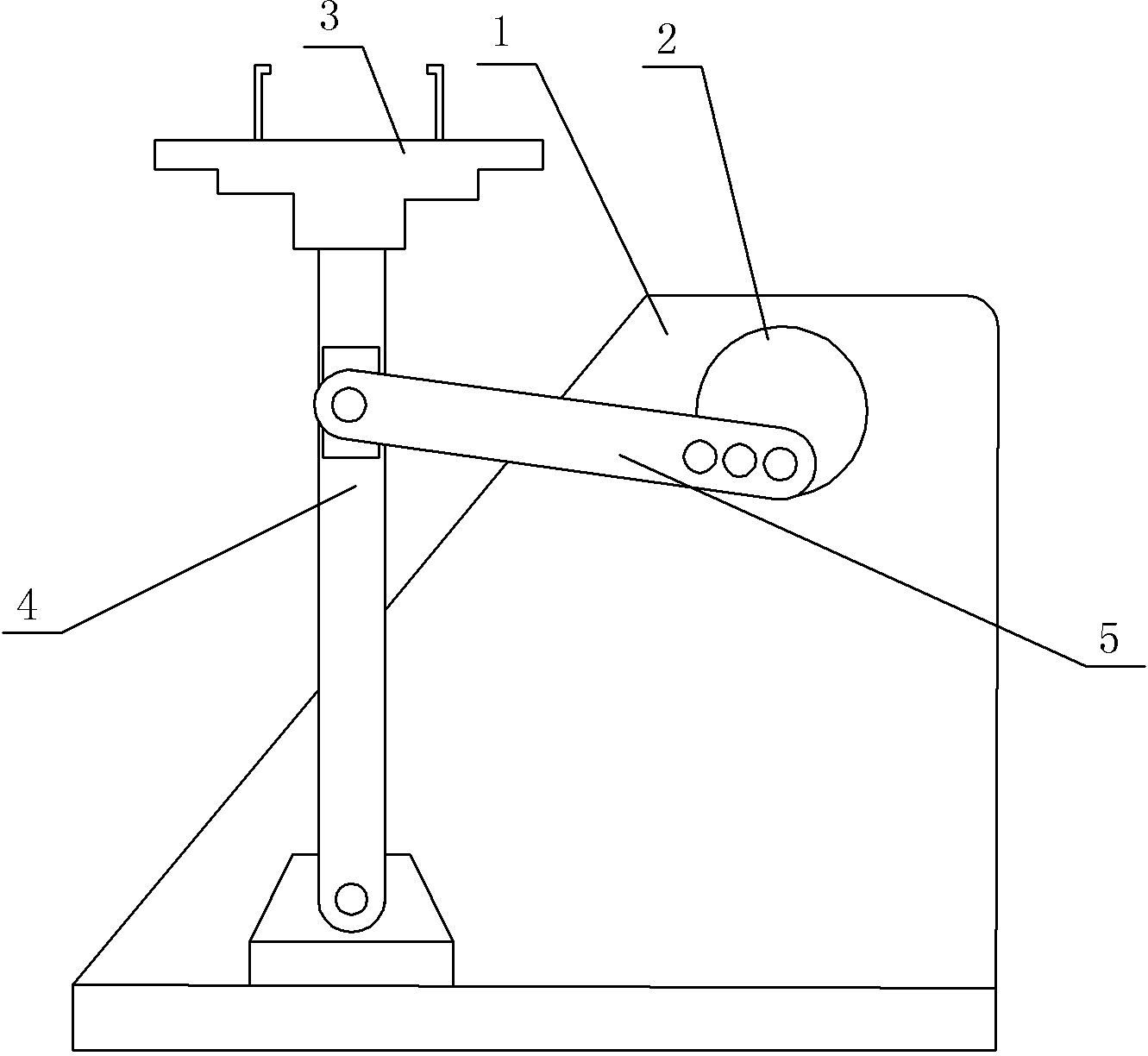

[0010] according to figure 1 As shown, the reciprocating motion mechanism for the tiller blade processing of the tiller in the embodiment of the present invention includes a frame 1, and also includes a driving disc 2 rotatably connected with the frame 1, a connecting rod 5 hinged at the edge of the driving disc 2 And the swing arm 4, one end of the swing arm 4 is hinged with the frame 1, the other end of the swing arm 4 is screwed with a worktable 3, and the worktable 3 is provided with a sharpening stone (not shown in the figure) and a fan (not shown in the figure) Out) and the clamp for holding the whetstone, the swing arm 4 is provided with a sliding groove in the middle, and the connecting rod 5 is hinged with a sliding block at one end away from the driving disc 2. The sliding block moves in the sliding groove in the middle of the swinging arm 4, and the connecting rod 5 A plurality of hinge holes are provided near one end of the driving circular plate 2.

[0011] What has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com